| Home | About Us | Contribute | Bookstore | Advertising | Subscribe for Free NOW! |

| News Archive | Features | Events | Recruitment | Directory |

CMP PROCESSING

Learn more about R&D chemical mechanical polishing by requesting our FREE informational CD.

| FREE subscription |

| Subscribe for free to receive each issue of Semiconductor Today magazine and weekly news brief. |

News

10 January 2008

Nextreme launches OptoCooler thermoelectric module

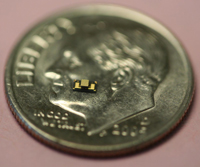

Nextreme Thermal Solutions Inc of Durham, NC, USA, which designs and manufactures microscale thermal and power management products, has announced the availability of the Ultra-High Packing Fraction (UPF) OptoCooler thermoelectric module, which addresses the latest cooling and temperature control requirements for optoelectronics, electronics, medical, military and aerospace applications. In particular, the new module has been optimized for laser diode, LED and advanced sensor products.

Developed in response to market demand for microscale cooling solutions that improve the performance of electronics without sacrificing efficiency, the UPF OptoCooler removes a maximum of 420mW of heat at 25°C ambient in an active footprint of only 0.55mm². As a result, the module can pump a heat density of up to 78W/cm². At 85°C, these values increase to 610mW and 112W/cm², respectively.

With Nextreme’s thin-film thermal bump technology at its core, the OptoCooler can be integrated directly into electronic and optoelectronic packaging to deliver more than 45°C of cooling for a wide variety of thermal management applications. For example, the module can be embedded within laser diode packages to control temperatures and maintain proper operating conditions for optimal performance. In addition, its ultra-fast, millisecond response time and broad temperature range capabilities can enable improved performance of the thermal cycling processes in a host of applications, Nextreme claims.

“The OptoCooler module is the industry’s first thermoelectric device to offer a heat pumping density in excess of 70W/cm², a ten-fold increase in heat pumping capacity over conventional TEC modules,” claims VP of engineering Dave Koester. “This development enables direct cooling of a laser diode on a scale that is similar to the diode itself,” he adds. “This significantly improves efficiency and offers new, integrated packaging options that were previously unavailable.”

The UPF OptoCooler module serves as Nextreme’s unit building block for all future discrete products. It is manufactured in high volumes with Nextreme’s Thermal Copper Pillar Bump process, which is based on an established electronic packaging approach that scales well into large arrays, the firm claims. The process integrates thin-film thermoelectric material into the solder bumped interconnects that traditionally provide mechanical and electrical functionalities in existing high-performance/high-density ICs. But, unlike conventional solder bumps, Nextreme bumps function as solid-state heat pumps on a microscale. The thermal bumping process can be implemented at the system-level, package-level or wafer-level, as well as in discrete modules such as the OptoCooler.

The new modules can be purchased for $12 in unit volumes of 1000s. Pricing for smaller or larger volumes are available upon request.

The new modules can be purchased for $12 in unit volumes of 1000s. Pricing for smaller or larger volumes are available upon request.

*Nextreme will be demonstrating the OptoCooler at the Photonics West conference in San Jose, CA, USA (22-24 January).

See related item:

Nextreme adds high-power packaging expert as VP of marketing & business development

Search: Laser diodes LEDs

Visit: www.nextreme.com