| Home | About Us | Contribute | Bookstore | Advertising | Subscribe for Free NOW! |

| News Archive | Features | Events | Recruitment | Directory |

News

29 June 2010

LayTec appoints sales engineer for business development in South Korea and Russia

LayTec GmbH of Berlin, Germany, which provides in-situ optical metrology systems for thin-film processes, has appointed Dr Oliver Schulz as a new sales engineer, responsible for handling customer relations, coordinating sales activities and supporting distributors in South Korea and Russia.

Schulz obtained his diploma and Ph.D. degree at the Technical University (TU) Berlin, working on Zn(Cd)Se-based semiconductor lasers and (Ga)As quantum dot lasers emitting in the green and infrared wavelength ranges, respectively. At TU Berlin he also gained broad experience in device processing technology, especially plasma-based processes (e.g. PECVD and ICP-RIE). In 2007 he joined epiwafer foundry Azzurro Semiconductors AG, a spin-off of Germany’s Otto-von-Guericke Universität Magdeburg, as a senior R&D manager. At Azzurro, Schulz dealt with gallium nitride on silicon (GaN-on-Si) technology, in particular with FETs on large-diameter silicon substrates.

FBH uses Pyro 400 to measure GaN surface temperature uniformity

At the 15th International Conference on Metal Organic Vapor Phase Epitaxy (IC MOVPE XV) in Lake Tahoe, NV, USA (23–28 May), Veit Hoffmann of Germany’s Ferdinand Braun Institute Berlin (FBH) presented how, to control the growth of GaN-based laser diodes, LayTec’s new Pyro 400 tool has been used for direct temperature measurements on the wafer surface and its EpiCurve TT tool has been used to control wafer bowing and pocket temperature (V. Hoffmann et. al. ‘Uniformity of the wafer surface temperature during MOVPE growth of GaN-based laser diode structures on GaN and sapphire substrate’, submitted to J. Crystal Growth, ICMOVPE XV proceedings).

Hoffmann investigated the influence of different substrate materials (sapphire and GaN) and different growth conditions on wafer bow and the temperature uniformity during growth of the laser’s active region.

Hoffmann investigated the influence of different substrate materials (sapphire and GaN) and different growth conditions on wafer bow and the temperature uniformity during growth of the laser’s active region.

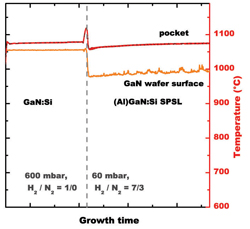

Graphic: Pocket temperature measured by EpiCurve TT at 950nm (red curve) and GaN surface temperature measured by Pyro 400 (orange curve).

The figure shows an example of temperature measurements during the growth of AlGaN buffers on GaN. After changing the pressure from 600mbar to 60mbar and H2 gas to 70%H2/30%N2, the temperature dropped. The EpiCurve TT, which measures the 950nm pyro emission, showed that the pocket temperature (red curve) fell insignificantly, whereas the GaN surface temperature measured by the Pyro 400 fell by 75K (orange curve). This difference could not have been detected without the Pyro 400, says LayTec.

The study proves that the wafer surface temperature is affected by changes in pressure and gas phase much more strongly than the pocket temperature. This is because the modified thermal conductivity and the thermal capacity of the gases at low reactor pressure results in an increased vertical temperature gradient between the pocket and ceiling.

“With Pyro 400 we obtain valuable information about temperature effects that are not visible to the conventional infrared pyrometers,” comments Hoffmann. “This is the best method to improve the uniformity of the surface temperature,” he believes. By using a convex pre-bowed GaN substrate and changing the growth conditions, the active region could hence be deposited on nearly flat wafers with homogeneous temperature distribution.

![]() Search: LayTec Pyro 400 GaN MOCVD

Search: LayTec Pyro 400 GaN MOCVD

Visit: www.laytec.de