| Home | About Us | Contribute | Bookstore | Advertising | Subscribe for Free NOW! |

| News Archive | Features | Events | Recruitment | Directory |

News

15 June 2010

Low threshold for m-plane nitride semiconductor lasing

Threshold currents for aluminum gallium nitride (AlGaN) cladding-free m-plane indium gallium nitride (InGaN) laser diodes (LDs) have been reduced to levels comparable to those for traditional ‘state-of-the-art’ c-plane devices in research carried out by University of California Santa Barbara (UCSB) [R. M. Farrell et al, Appl. Phys. Lett., vol96, p231113, 2010].

UCSB has been working since 2007 on m-plane LDs without AlGaN cladding. LDs grown in the m-plane direction of the nitride semiconductor crystal structure do not suffer from high polarization field effects seen in devices grown in different directions such as the c-plane. These polarization fields can reduce recombination into photons by tending to separate the electron–hole charge carriers, decreasing the effectiveness of light-emitting devices.

The use of non-polar and semi-polar nitride semiconductor material is predicted to boost optical gain, an important aspect of achieving laser emission. Non-polar LEDs have achieved 50% external quantum efficiency, and semi-polar material has been used to extend the wavelength range of nitride semiconductor LDs from the blue–violet region into the green region. UCSB has also recently done some work on semi-polar LDs [see: Yet another angle on nitride laser diodes].

Cladding layers in LDs are used to confine the optical field, creating the conditions needed for stimulated emission. However, the AlGaN material often used for this has a large lattice mismatch with the underlying structures and is therefore difficult to grow with sufficient quality (e.g. without cracking, and with low defect density, etc).

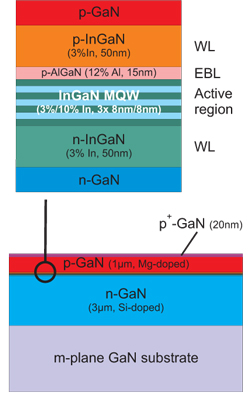

Figure 1: Epilayer structure of UCSB’s latest laser diodes without AlGaN cladding. EBL = electron-blocking layer, WL = waveguide layer.

Figure 1: Epilayer structure of UCSB’s latest laser diodes without AlGaN cladding. EBL = electron-blocking layer, WL = waveguide layer.

The new UCSB LDs (Figure 1) were grown using metal-organic chemical vapor deposition (MOCVD) on free-standing GaN substrates supplied by Mitsubishi Chemical. InGaN separate-confinement heterostructures (SCH) were used to waveguide the optical field. The only AlGaN in the structure is a very thin 15nm electron-blocking layer, designed to stop electrons from overshooting the active region and recombining in the p-type hole injection layers.

The material was formed into standard ridge-waveguide LD structures with self-aligned dry etch and insulator lift-off. The ridges were aligned in the c-direction of the nitride semiconductor crystal structure. Mirror facets for the laser cavity were formed using dry etch. Silicon dioxide was used for electrical insulation. Palladium-gold and aluminum-gold were used for the p- and n-type contacts, respectively.

Characterization was carried out under controlled temperature conditions (mostly 20°C). Pulsed testing was carried out at 1kHz with a width of 2μsec (0.2% duty cycle). The measurements were made with one device before and after facet coating with a highly reflective (HR) six-period sequence of quarter-wavelength layers of silicon dioxide/tantalum pentoxide (SiO2/Ta2O5).

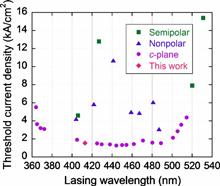

Figure 2: Dependence of best reported threshold current density on lasing wavelength for semi-polar, non-polar, and c-plane InGaN/GaN LDs.

Figure 2: Dependence of best reported threshold current density on lasing wavelength for semi-polar, non-polar, and c-plane InGaN/GaN LDs.

Before coating, the threshold was 584mA (2.16kA/cm2 density); this was reduced to 416mA (1.54kA/cm2) after coating, “which is comparable to the best reported threshold current densities for c-plane LDs” (Figure 2). The after-coating threshold of 5.3V is relatively low for such a device, and comparable to values that are typical for c-plane LDs, the researchers say. Coating reduces the slope efficiency from 0.56W/A to 0.26W/A. This corresponds to an internal loss of 7/cm.

Coating also increased the lasing wavelength slightly – red-shifting it from 412.0nm to 412.9nm. Since there are no polarization fields to shift the emission spectrum, a blue-shift in the sub-threshold spectrum is attributed to ‘band filling’; as the injection current increases and the bands fill up, the energy separation between the hole and electron states increases, giving a blue-shift in emission. Since the threshold is lower in the coated device, it starts lasing when the bands are less full, giving the slight red-shift in lasing wavelength.

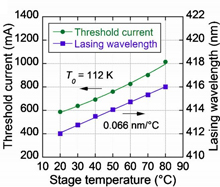

Temperature variation of the threshold for the uncoated device gave a characteristic temperature (T0) of 112K – “comparable to values reported for early c-plane LDs” (Figure 3).

Temperature variation of the threshold for the uncoated device gave a characteristic temperature (T0) of 112K – “comparable to values reported for early c-plane LDs” (Figure 3).

Figure 3: Dependence of threshold current and lasing wavelength on stage temperature.

The researchers believe that even lower threshold currents could be achieved using lower numbers of quantum wells.

The work was supported by the Solid State Lighting and Energy Center (SSLEC) at UCSB and the US Defense Advanced Research Projects Agency (DARPA) Visible InGaN Injection Lasers (VIGIL) program.

![]() Search: InGaN laser diodes

Search: InGaN laser diodes

Visit: http://link.aip.org

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.