| Home | About Us | Contribute | Bookstore | Advertising | Subscribe for Free NOW! |

| News Archive | Features | Events | Recruitment | Directory |

News

15 March 2010

Increased UV power from diamond LEDs enables E. coli sterilization

Researchers in Japan have increased deep ultraviolet output power to 0.3mW from diamond light-emitting diodes (LEDs) and used the radiation as a sterilizing agent against Escherichia coli (E. coli) bacteria. The latest UV LEDs emit at wavelengths around 235nm, corresponding to the energy of the diamond exciton (electron–hole bound state). The external quantum efficiency was 0.01%. These results were presented at the recent nano tech 2010 exhibition and conference in Tokyo.

The 235nm wavelength is short enough to give the energy that is needed (~260nm) to break the chemical bonds between corresponding base pairs within the deoxyribonucleic acid (DNA) and ribonucleic acid (RNA) polymers of micro-organisms such as bacteria and viruses. Rather than forming the usual hydrogen-bonded thymine-adenine (T-A) base pairs in the DNA double-helix, neighboring thymine pairs on a single chain are transformed to bond covalently, disrupting the genetic code.

Presently, bulky 254nm mercury lamps are most often used for such UV sterilization. UV sterilization can be effective also against bacteria that are resistant to thermal treatments. However, breakage of mercury lamps poses environmental hazards.

Development of the LED was performed by two scientists, Satoshi Yamasaki and Toshiharu Makino, from the Energy Technology Research Institute (ETRI) of the National Institute of Advanced Industrial Science and Technology (AIST). The scientists worked in cooperation with the National Institute for Materials Science (NIMS) and Japanese industrial diamond producer Syntek. The sterilization application was developed with lighting and optical applications developer Iwasaki Electric.

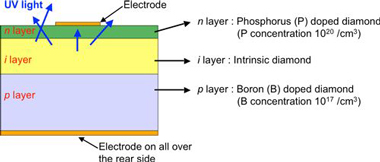

The diamond was doped with phosphorous and boron to create n-type (electron majority carrier) and p-type (hole majority carrier) layers, respectively, on either side of an undoped intrinsic region (Figure 1).

Figure 1: Cross section of diamond UV LED.

The 0.3mW output power is close to what is needed for the practical application of UV sterilization. The hope is to develop portable germicidal lamps.

AIST has been developing diamond for UV emission for some time, working on the synthesis, electronic device technology, and basic physics of the material. Devices based on diamond exciton UV emission were presented in 2006. Some of this work also involved Kobe Steel, in addition to the companies and organizations mentioned above. Some of the funding originated from the ‘Research and Development of Nanodevices for Practical Utilization of Nanotechnology’ project supported by Japan’s New Energy and Industrial Technology Development Organization (NEDO). Last year, the scientists produced a 30μW (0.03mW) device.

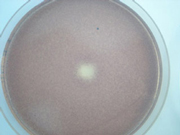

Figure 2: Agar plate on which E. coli was grown. UV light was directed at the center by the diamond LED, and incubation was for 24 hours. At the point of irradiation, E. coli was killed; in the surrounding purple area, proliferation was seen.

Figure 2: Agar plate on which E. coli was grown. UV light was directed at the center by the diamond LED, and incubation was for 24 hours. At the point of irradiation, E. coli was killed; in the surrounding purple area, proliferation was seen.

The sterilization experiments were carried out with 0.1mW pulsed operation of the LEDs. The pulses were 10msec with 90msec intervals. The distance between the LED and the bacterial growth medium (agar) was about 2mm. With 100sec of UV irradiation (carried out over 1000sec), a 10mm-diameter region of the agar showed no E. coli growth after 24 hours of incubation (Figure 2). Outside of the irradiated region, the E. coli grew normally.

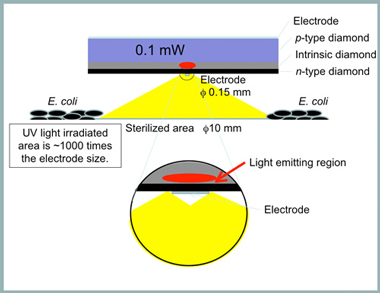

The scientists are now working to enhance the emission intensity by improving the device structure to increase the light extraction efficiency . Presently, most of the light emitted from the intrinsic layer is blocked by the titanium electrode and absorbed within the device itself (Figure 3). Only light generated near the circumference of the electrode escapes from the device, providing radiation for sterilization.

Figure 3: Red areas: light-emitting regions. Light escaping from circumference of electrode was used for sterilization.

Further tests of the UV LED radiation’s rapid sterilization capability are also planned.

An alternative to diamond that is being developed for UV LEDs is nitride semiconductor materials. US firm Sensor Electronic Technology reported 2mW 245–247nm continuous-wave output from a 2x2 arrangement of four aluminum gallium nitride (AlGaN) devices.

See related item:

Deep ultraviolet power boost at shorter wavelengths

![]() Search: LEDs Deep-ultraviolet LEDs

Search: LEDs Deep-ultraviolet LEDs

Visit: www.aist.go.jp/aist_e/latest_research

Visit: http://unit.aist.go.jp/energy/index_e.htm

Visit: www.syntek.co.jp/en

Visit: www.eye.co.jp

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.