- News

27 January 2011

Dai Nippon Printing uses Eulitha’s PHABLE technology

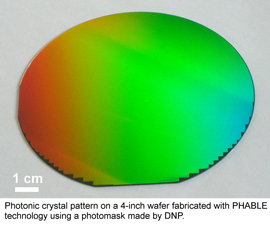

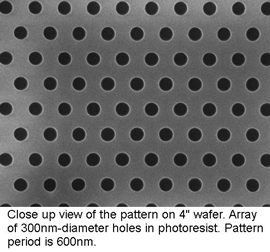

Photomask maker Dai Nippon Printing Co Ltd (DNP) of Japan has patterned 4-inch wafers using the proprietary PHABLE (Photonics Enabler) technology of nanolithography firm Eulitha AG (a spin-off of the Paul Scherrer Institute in Villigen, Switzerland). Photonic crystal patterns with a period of 600nm and hexagonal symmetry were created uniformly over the 4” wafers.

PHABLE is a mask-based ultraviolet (UV) photolithography technology that targets production of photonic structures such as photonic crystals, diffraction gratings and anti-reflection surfaces. Eulitha says that high-throughput fabrication of such patterns over large areas is required for the manufacturing of future high-performance devices in fields including LEDs, solar cells and flat-screen displays. In PHABLE, a mask is illuminated with a UV beam to form a high-resolution image that has a very large depth of focus, so substrates with non-flat surfaces can be patterned easily.

PHABLE is a mask-based ultraviolet (UV) photolithography technology that targets production of photonic structures such as photonic crystals, diffraction gratings and anti-reflection surfaces. Eulitha says that high-throughput fabrication of such patterns over large areas is required for the manufacturing of future high-performance devices in fields including LEDs, solar cells and flat-screen displays. In PHABLE, a mask is illuminated with a UV beam to form a high-resolution image that has a very large depth of focus, so substrates with non-flat surfaces can be patterned easily.

The necessary high-resolution mask with the same 4” area as the final pattern was produced by DNP on a standard quartz/Cr plate. UV photolithography exposures were performed on a PHABLE-R lithography tool made by Eulitha. Photonic crystal patterns consisting of circular holes on a 600nm-period hexagonal lattice were printed in a commercially available photoresist coated on silicon wafers. The patterns that were produced were highly uniform over the whole 4” area of the wafers.

Eulitha says that the demonstration of uniform patterning on 4” substrates is an important milestone as most targeted applications require patterning of large areas. For example, the high-brightness LED industry is switching to 4” and 6” wafers from the traditional 2” base. Photonic crystal structures that enhance light extraction in LEDs or patterned sapphire substrates that improve performance of LEDs grown on them can be fabricated using PHABLE technology. Similarly, the technology can be used to produce the required substrates for nanowire-based LED or solar cell applications.

Eulitha says that the demonstration of uniform patterning on 4” substrates is an important milestone as most targeted applications require patterning of large areas. For example, the high-brightness LED industry is switching to 4” and 6” wafers from the traditional 2” base. Photonic crystal structures that enhance light extraction in LEDs or patterned sapphire substrates that improve performance of LEDs grown on them can be fabricated using PHABLE technology. Similarly, the technology can be used to produce the required substrates for nanowire-based LED or solar cell applications.

Eulitha currently offers samples and wafer batch processing services to companies and researchers developing nanostructure-based products. It also offers laboratory lithography tools for 2–4” wafers that are suitable for product development.

Eulitha unveils PHABLE UV litho technology for photonics patterning

Eulitha Photonics patterning LEDs UV photolithography