- News

30 May 2011

ZnO particle enhancement to nitride LED light extraction

Researchers at Chonbuk National University in South Korea have developed a technique to improve light extraction efficiency in nitride LEDs using zinc oxide (ZnO) nanoparticles in an indium tin oxide (ITO) film to reduce total internal reflection at the air interface [Beo Deul Ryu et al, J. Appl. Phys., vol109, p093116, 2011]. The resulting device has up to 39% improved output power without impacting the electrical performance.

A good LED depends on both efficient production of photons in the active layers and extraction from the device into the outside world. Extraction is a particular problem in nitride devices since these materials have high refractive indices. For example, gallium nitride (GaN) has a refractive index of 2.5. This severely restricts the angles at which light incident on the GaN–air interface can be transmitted out rather than totally reflected back into the device.

A number of different techniques have been directed at improving light extraction efficiency of nitride LEDs, usually through some sort of patterning of the device emission surface or adding layers of different materials.

Some groups have recently used zinc oxide nano-tips or nano-rods to enhance light extraction by up to 70%. Unfortunately, these devices also have an increased forward voltage for operation, which means that energy is wasted. The increase in forward voltage is attributed to damage of the transparent p-electrode caused by the high-temperature ZnO nano-tip or nano-rod growth method.

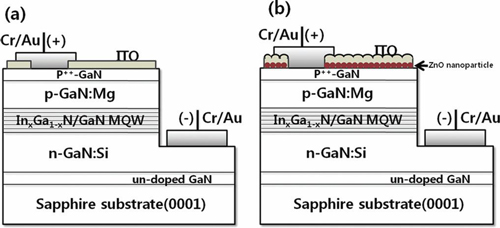

The Chonbuk method is to use already formed ZnO nanoparticles that can be spin-coated onto the epitaxial nitride semiconductor wafer. The epitaxial structure (Figure 1) was grown on sapphire using metal-organic chemical vapor deposition (MOCVD). The active region of the device consisted of a five-period multi-quantum well of InGaN/GaN pairs with a blue emission wavelength of about 460nm.

Figure 1: Schematic cross section of (a) conventional LED and (b) LEDs using ZnO nanoparticles.

Before further processing, the LED wafer was cleaned with acetone, isopropanol and deionized water. The ZnO particles (~20nm in diameter) dispersed in methanol were then spin coated onto the LED wafer surface. The spin cycle consisted of three steps: 500 rotations per minute (rpm) for 10 seconds, 1500rpm for 30 seconds, and 3000rpm for 30 seconds. Various numbers of spin cycles were used to vary the density of ZnO particles on the surface (Table 1). The particles were then covered with 200nm of indium tin oxide (ITO) that was annealed at 600°C for 30 seconds in air.

Sample |

Spin cycles |

ZnO particle density |

A |

1 |

4.14x1010/cm2 |

B |

2 |

5.32x1010/cm2 |

C |

3 |

8.31x1010/cm2 |

D |

5 |

1.40x1011/cm2 |

Reference |

0 |

0/cm2 |

Table 1.

Dilute nitric acid was used to remove unwanted ZnO particles and ITO. Mesa structures were created using inductively coupled plasma (ICP) etching. The metal contacts consisted of chromium-gold.

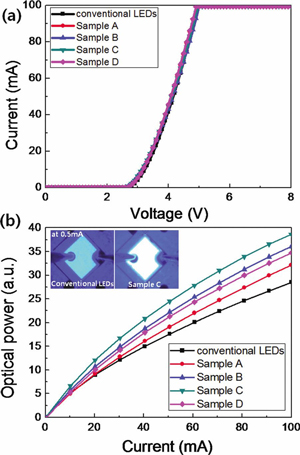

The current–voltage (I–V) characteristics were unaffected by different levels of ZnO nanoparticles (Figure 2), unlike other treatments designed to improve the extraction efficiency such as ZnO nano-tips or nano-rods. The forward voltage at 20mA was around 3.45V. At the same drive current (20mA), light output powers for samples A, B, C and D were increased over a conventional device by 9%, 27%, 39% and 19%, respectively.

The current–voltage (I–V) characteristics were unaffected by different levels of ZnO nanoparticles (Figure 2), unlike other treatments designed to improve the extraction efficiency such as ZnO nano-tips or nano-rods. The forward voltage at 20mA was around 3.45V. At the same drive current (20mA), light output powers for samples A, B, C and D were increased over a conventional device by 9%, 27%, 39% and 19%, respectively.

The researchers ascribe the improved light extraction to light scattering by the ZnO nanoparticles and to the nano-rough morphology of the covering ITO film. However, with the highest density of nanoparticles, one sees increased scattering/reflection, reducing the amount of extracted light.

The researchers comment: “both the nano-rough ITO surface and the ZnO nanoparticles presumably improve the angular distribution of emissions in the optical phase space, leading to a larger escape cone at the nano-rough ITO film. Moreover, the reduction in the total internal reflection as a result of the difference in refractive indices at the GaN/ZnO/ITO interfaces has a significant impact on the enhancement of light output power.”

Figure 2: (a) Current–voltage and (b) light output power–current characteristics of samples A, B, C and D. Inset in (b): optical microscopic photographs of a conventional LED and sample C.

The refractive indices of GaN, ZnO, and ITO are 2.5, 2 and 1.9, respectively

Some measurements were made of transmittance of light by the nanoparticle layers before and after deposition of the ITO film. Without the film, samples A, B, C and D had transmittances of 98%, 97%, 93% and 90%, respectively. Planar ITO film (i.e. without ZnO nanoparticles) had a transmittance of 90%, and samples A, B, C and D had transmittances of 86%, 85%, 83%, and 81%, respectively.

The researchers believe that greater enhancement can be achieved through optimizing the nanoparticle dispersion technology.

ZnO nanoparticles InGaN/GaN MOCVD LEDs Sapphire substrates

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.