- News

24 October 2012

Improving nitride semiconductor LEDs with ZnO nanorods on rear surface

Researchers in Korea and India have used zinc oxide (ZnO) nanorods on the rear side to improve light output from nitride semiconductor light-emitting diodes (LEDs) grown on c-plane sapphire [Joo Jin et al, Jpn. J. Appl. Phys., vol51, p102101, 2012]. The researchers were based at Chonbuk National University, Republic of Korea, and Sona College of Technology, India.

Researchers around the world are seeking ways to improve nitride LEDs for high-brightness lighting applications at low production and operation cost. One factor that limits external quantum efficiency (EQE) is poor light extraction due to the large refractive index difference between nitride semiconductor and air, resulting in a narrow escape cone of around 23°. A number of techniques have been tried for improving light extraction, but they tend to involve expensive processes or they damage the underlying performance of the LED.

One way that has been tried is to use ZnO nanorods on the transparent top p-electrode, where 50% improved light output was achieved with a metal-organic chemical vapor deposition. However, the high-temperature process damaged the p-electrode, reducing electrical performance. Some researchers have tried low-temperature deposition using aqueous solutions, but these needed time- and energy-consuming multi-processing steps.

The Korea/India LEDs were constructed from epitaxial material produced through metal-organic chemical vapor deposition (MOCVD) on c-plane sapphire. The multi-quantum well (MQW) active region consisted of five indium gallium nitride (InGaN) wells in gallium nitride (GaN) barriers. The blue emission wavelength was ~460nm.

The epitaxial material was subjected to an inductively coupled etch, producing 254µm x 584µm mesa regions. The raised p-electrode was covered with 200nm indium tin oxide (ITO) transparent conductor. Chromium and gold (Cr/Au) were used for contact metals.

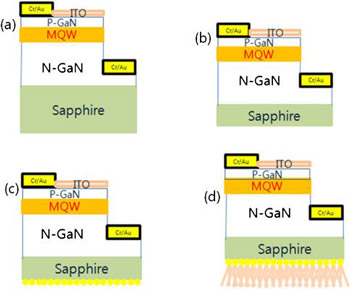

The sapphire substrate was prepared for the ZnO deposition by polishing (Figure 1). The polished bottom sapphire surface (PBSS) was then seeded with ZnO by spin coating. The ZnO seeds were then developed into nanorods using solution growth. The time of exposure to solution was varied to give different samples: A for 0 hours (conventional LED), B for 0.5 hours, C for 1 hour, D for 2 hours, and E for 3 hours.

The sapphire substrate was prepared for the ZnO deposition by polishing (Figure 1). The polished bottom sapphire surface (PBSS) was then seeded with ZnO by spin coating. The ZnO seeds were then developed into nanorods using solution growth. The time of exposure to solution was varied to give different samples: A for 0 hours (conventional LED), B for 0.5 hours, C for 1 hour, D for 2 hours, and E for 3 hours.

Figure 1: Schematic of process for growing ZnO nanorods on rear side of PBSS: (a) basic LED structure, (b) sapphire polishing, (c) ZnO seed deposition, and (d) growth of ZnO nanords.

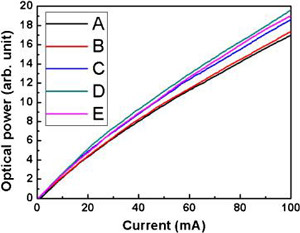

The resulting nanorods are randomly oriented on the sapphire surface with constant diameters but length varying with the length of exposure to the solution: ~370nm for sample B, ~650nm for C, ~900 for D, and ~1300nm for E. The effect of the nanorods on 460nm light is to increase reflectance to almost 18% for sample E. There is almost no effect on forward voltage, which is in the range 3.40-3.43V for all LEDs at 20mA. Also, at 20mA, the light output from sample D was 15% higher than that without nanorods (Figure 2).

Figure 2: Light output power of LEDs with and without ZnO nanorods.

Figure 2: Light output power of LEDs with and without ZnO nanorods.

The researchers comment: “Compared with the conventional LED the optical output power of the LEDs with ZnO nanorods was enhanced, indicating that more light escapes from the rear side of the LEDs through ZnO nanorods.”

The light output with the even longer ZnO nanorods of sample E was less, at only 9% higher than the conventional LED. “The decline in light output power after a critical nanorod length can be attributed to the light loss occurring via absorption and appearance of air-voids in the interlayer between the nanorod arrays and silver paste,” the researchers write.

The researchers believe that the enhanced optical output power of the LEDs with ZnO nanorods was due to the high level of heat dissipation through the nanorods due to both the high thermal conductivity of ZnO and the high surface/volume ratio of nanorod arrays, along with the increased probability of light emission in all directions with reduced absorption.

The angular properties of the emission were also measured. The divergence angles to half maximum emission intensity at 20mA were 157°, 162°, 162°, 169° and 153° for samples A to E, respectively. The broader emission with nanorods can be attributed to waveguiding and scattering effects of the inclined nanorods.

The low divergence for LED E was explained as being due to the appearance of air voids in the interlayer between ZnO nanorods and silver paste used to make thermal connection with the packaging structure.

| Materials | Thermal conductivity (W/m-K) |

| ZnO | 1.47 |

| Air | 0.032 |

| Silver paste | 2–25 |

| Sapphire | 0.35 |

Table 1: Comparison of thermal conductivity of relevant materials.

The thermal resistances of the connection with the silver paste were 40.5°C/W, 38.7°C/W, 35.9°C/W, 25.1°C/W and 29.4°C/W for samples A to E, respectively. The samples with nanorods benefitted from the high thermal conductivity of ZnO (Table 1). The up-tick for LED E can again be attributed to air voids/discontinuity between the nanorods and silver paste.

Blue LEDs ZnO nanorods MOCVD Sapphire substrates InGaN wells GaN barriers

http://jjap.jsap.jp/link?JJAP/51/102101

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.