- News

9 April 2013

Sol Voltaics unveils SolInk nanomaterial to boost PV module performance by 25%

Sol Voltaics AB of Ideon Science Park, Lund, Sweden has unveiled SolInk, a nanomaterial that promises to boost the efficiency of crystalline silicon or thin-film solar modules by up to 25%, leading to solar power plants and rooftop solar arrays that can generate far more electricity than the best systems currently available commercially, it is claimed.

The firm reckons that the increase in efficiency will allow SolInk-enhanced panels to deliver power at prices that can compete directly against electricity from fossil-fuel plants while improving the economics for manufacturers. Global demand for solar energy is expected to grow from 29.8GW of new solar installations in 2012 to 50.8GW in 2016, according to Greentech Media.

“About two-thirds of the cost of commercial solar systems revolves around land, labor costs and other factors that solar developers cannot directly control,” says Sol Voltaics’ CEO David Epstein. “By raising the efficiency of solar modules, we give solar manufacturers the opportunity to sell more valuable, higher-margin products and solar developers the opportunity to generate more power ‐ at a lower price - with essentially the same physical assets,” he adds.

Picture:

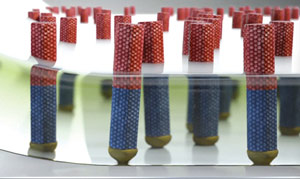

SolInk nanowires grown by Aerotaxy process.

Picture:

SolInk nanowires grown by Aerotaxy process.

Sol Voltaics’ strategy revolves around two fundamental technologies: gallium arsenide nanowires measuring 1-2 microns in length and 100-200nm in diameter (the active ingredient in SolInk) and Aerotaxy (a process for producing nanowires created by company founder and Lund University professor Lars Samuelson).

GaAs has been used in solar for years (e.g. in orbiting satellites) because of its reliability and high energy conversion efficiencies, but GaAs solar cells typically cost far more to produce than crystalline silicon or thin-film cells, confining the material to niche market segments, says the firm.

SolInk reduces the cost by minimizing materials: less than a gram of nanowires is added to the surface of crystalline silicon panels. With SolInk, module makers can make commercially feasible, high-efficiency GaAs solar modules or multi‐junction solar modules combining GaAs nanowires on top of crystalline silicon, reckons the firm.

SolInk also enables light concentration without the use of optics or mechanical components, Sol Voltaics adds. Nanowires need to cover only a small portion of the surface area of a crystalline silicon or thin-film solar cell to achieve substantially all of the benefits of adding GaAs. In the academic journal Science earlier this year, Lund University and Sol Voltaics researchers demonstrated that indium phosphide (InP) nanowires covering just 12% of the substrate surface produced a solar cell with an efficiency of 13.8%. The results were certified by Germany’s Fraunhofer Institute. The phenomenon, called wave concentrated photovoltaics (WCPV), combined with the other advantages of GaAs nanowires leads to the high performance of SolInk, it is claimed.

Aerotaxy manufacturing method

Nanowires and nanotubes are typically produced via a process of epitaxial crystal growth on a substrate. But because of the inherent physical limits of the epitaxial process, nanoparticles often need to be grown in place or harvested and sorted in batch processes that can be both time-consuming and expensive.

Instead, Aerotaxy creates nanomaterials by suspending and mixing active materials in carrier gas streams. The active materials bond to form larger, uniform structures while in flight: nanowires are literally grown in air. Aerotaxy can hence generate tens of billions of nanowires per second on a continuous basis. The finished nanowires can be integrated into a solar panel or other products, or can be stored indefinitely. A paper published in Nature late last year details how professor Samuelson and his team used Aerotaxy to manufacture GaAs nanowires (‘Continuous gas-phase synthesis of nanowires with tunable properties’ by Magnus Heurlin et al, Nature, 492, 90–94 (6 December 2012); doi:10.1038/nature11652).

“The results have been far better than we ever expected,” says Samuelson. “We understand how different materials react or bond to one another,” he adds. “With Aerotaxy, we essentially create an atmosphere where we can better harness those physical and chemical properties.”

Business model: selling SolInk, rather than modules

Rather than produce modules or sell capital equipment, Sol Voltaics will produce and sell SolInk to solar cell and module makers. Hence a single, relatively small manufacturing facility will be able to provide megawatts worth of materials, it is reckoned. Module makers likewise will be able to integrate new materials into their products without replacing existing production lines, the firm adds.

Sol Voltaics expects to produce functional solar cells with GaAs nanowires for demonstration by the end of 2013. Commercial production of SolInk-enhanced modules should begin in 2015 and move into volume production in 2016. Total invested capital to get into high‐volume commercial production will come to less than $50m, the firm estimates.

Founded in 2008, Sol Voltaics has previously raised $11m from private investors including Stockholm-based venture capital firm Industrifonden, Foundation Asset Management AB of Sweden, Teknoinvest AS, Provider, Nano Future Invest and Scatec Energy of Norway. The firm has also received public funding from the European Union, Vinnova, Nordic Innovation Center, and others. Sol Voltaics aims to raise $10-20m this year.

The firm reckons that other potential applications for Aerotaxy include producing nanomaterials for power electronics, LEDs, batteries and energy storage.

“The promise of nanotechnology has been held back by complexity, low yields and cost,” says Scatec’s chairman Alf Bjorseth. “Aerotaxy paves the way for integrating new materials into products in a streamlined manner.”

www.nature.com/nature/journal/v492/n7427/full/nature11652.html