- News

17 May 2013

Graphene foam as transparent conductive electrode for blue LEDs

Researchers in Korea have used three-dimensional (3D) graphene foam as a transparent conductor for the p-contact of blue nitride semiconductor light-emitting diodes (LEDs) [Byung-Jae Kim et al, Appl. Phys. Lett., vol102, p161902, 2013]. The team consisted of engineers from Korea University, Sunchon National University, and Hongik University.

The effect of using graphene foam was to reduce the forward voltage by 26% and to increase light output by 14%. Both factors suggest improved power efficiency. Ordinary 2D graphene has previously been tried as transparent conductive electrodes in nitride LEDs with mixed success. However, up to now, graphene foam has not previously been applied to light emitting or absorbing devices (e.g. solar cells).

Many researchers are exploring graphene as an alternative to indium tin oxide (ITO), which increases in price with indium supply shortages. Also, the transmission of light cuts off in ITO in the ultraviolet range.

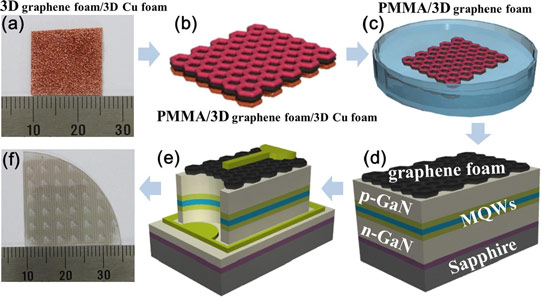

Commercial 3D graphene foam was used, produced on 3D copper foam using chemical vapor deposition (CVD). The material was spin-coated with poly(methyl methacrylate) (PMMA) and the copper etched away in ammonium sulfate ((NH4)2S2O8) solution (Figure 1). The graphene foam was cut into a square and transferred to the p-type gallium nitride (p-GaN) layer of a commercial blue LED nitride epitaxial material on sapphire substrate. The assembly of graphene foam on nitride semiconductor structure was fabricated into LED devices with plasma-etched mesas, titanium/aluminium/nickel/gold contacts with the n-GaN layer, and titanium/gold n- and p-contact pads.

Figure 1: Fabrication of blue LEDs with 3D graphene foam-based transparent conductive electrodes: (a) 3D graphene foam grown on 3D Cu foam; (b) spin-coating with PMMA; (c) wet etch of copper; (d) transfer of 3D graphene foam coated to p-GaN layer blue LED material and removal of PMMA; (e) and (f) blue LED devices fabricated with standard processes.

Graphene foam suffers from reduced transmittance compared with bilayer graphene. At 438nm wavelength, the transmittance of foam is 71%, while that of a bilayer is 95%. However, the foam is closer to 150nm ITO’s 75% transmittance at the same wavelength. The researchers point out that foam does have advantages over bilayer graphene such as low mass density, large surface area, high thermal and electrical conductivity, and good mechanical stability. The foam has a sheet resistance of ~800Ω/square, compared with 1500-3000Ω/square for 2D graphene films.

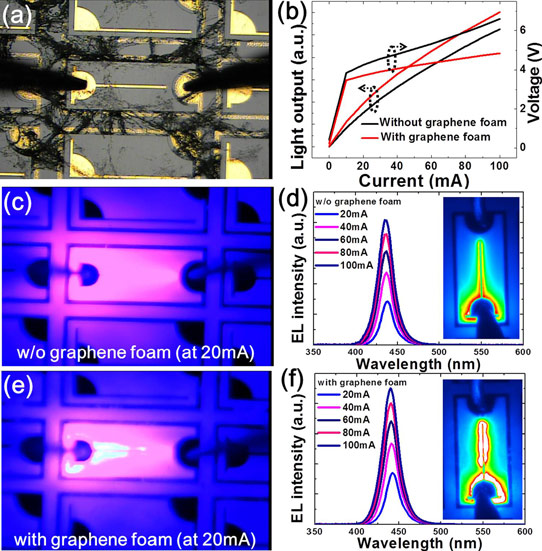

The LED chips measured 200μm x 500μm. At 100mA current injection, the forward voltage was 4.85V while without the foam the value was increased to 6.61V (Figure 2). Also, light output increased by 14% at 100mA from the better current-spreading capability of the foam.

Figure 2: (a) Optical microscope image of blue LED devices with graphene foam transparent conductive electrode. (b) Light output and current versus voltage (L-I-V) characteristics of blue LEDs with/without graphene foam. (c) Electroluminescence (EL) image of blue LED device without graphene foam at 20mA. (d) EL spectra of blue LED without graphene foam in 20-100mA range. (e) EL image of blue LED with graphene foam at 20mA. (f) EL spectra of blue LED with graphene foam in 20-100mA range. Insets of (d) and (f) are optical light emission images from beam profiler without/with graphene foam.

The researchers comment that the fabrication process of graphene foam needs to be optimized. For example, the foam structure partially collapsed during the photolithography processing, which involves spin-coating of the photoresist, development, plasma etch, and lift-off steps. Some photolithography residue was seen in electron and optical micrograph images as structures with a spider-web appearance. Raman spectroscopy confirmed that the web-like material was not graphene.

Graphene foam Transparent conductor Blue LEDs GaN

http://link.aip.org/link/doi/10.1063/1.4801763

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.