- News

7 August 2014

High-brightness LEDs made from perovskite material

A hybrid form of perovskite - the same type of material that has recently been found to make highly efficient solar cells that could replace silicon - has been used to make low-cost, easily manufactured LEDs, potentially opening up a wide range of commercial applications in future, such as flexible colour displays.

This particular class of semiconducting perovskites have generated interest in the solar cell field over the past several years, after professor Henry Snaith’s group at the UK’s University of Oxford found them to be remarkably efficient at converting light to electricity. In just two years, perovskite-based solar cells have reached efficiencies of nearly 20%, a level that took conventional silicon-based solar cells 20 years to reach.

Now, researchers at the University of Cambridge, University of Oxford and the Ludwig-Maximilians-Universität in Munich, Germany have demonstrated a new application for perovskite materials, using them to make high-brightness LEDs (Zhi-Kuang Tan et al, published online in Nature Nanotechnology; doi:10.1038/nnano.2014.149).

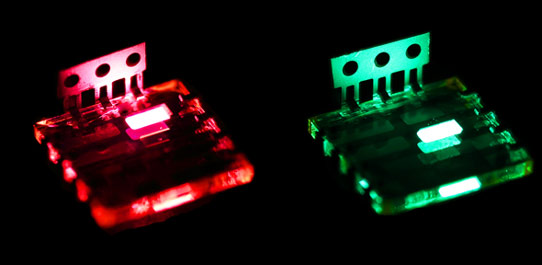

Picture: LEDs made from perovskite material. Credit: Zhi-Kuang Tan.

Perovskite is a general term used to describe a group of materials that have a distinctive crystal structure of cuboid and diamond shapes. They have long been of interest for their superconducting and ferroelectric properties. But in the past several years their efficiency at converting light into electrical energy has opened up a wide range of potential applications.

The perovskites that were used to make the LEDs are known as organometal halide perovskites, and contain a mixture of lead, carbon-based ions and halogen ions (halides). These materials dissolve well in common solvents, and assemble to form perovskite crystals when dried, so they are cheap and simple to make.

“We have designed the diode structure to confine electrical charges into a very thin layer of the perovskite, which sets up conditions for the electron-hole capture process to produce light emission,” says the paper’s lead author Zhi-Kuang Tan, a PhD student at the University of Cambridge’s Cavendish Laboratory.

The perovskite LEDs are made using a simple and scalable process in which a perovskite solution is prepared and spin-coated onto the substrate. This process does not require high-temperature heating steps or a high vacuum, and is therefore cheap to manufacture in large scale. In contrast, conventional methods for manufacturing LEDs make the cost prohibitive for many large-area display applications, the researchers say.

“The big surprise to the semiconductor community is to find that such simple process methods still produce very clean semiconductor properties, without the need for the complex purification procedures required for traditional semiconductors such as silicon,” comments professor Sir Richard Friend of the Cavendish Laboratory, who led the program at Cambridge.

“It’s remarkable that this material can be easily tuned to emit light in a variety of colours, which makes it extremely useful for color displays, lighting and optical communication applications,” says Tan. “This technology could provide a lot of value to the ever-growing flat-panel display industry,” he reckons.

The team is now looking to increase the efficiency of the LEDs and to apply the material to diode lasers, which are used in a range of scientific, medical and industrial applications, such as materials processing and medical equipment. The first commercially available LED based on perovskite could be available within five years, it is reckoned.

www.nature.com/nnano/journal/vaop/ncurrent/full/nnano.2014.149.html