- News

13 May 2014

Tailored last quantum barrier achieves more efficient, powerful GaN LEDs

Researchers based in Singapore and Turkey have demonstrated a last quantum barrier (LQB) structure for indium gallium nitride (InGaN) light-emitting diodes (LEDs) that improves the electron blocking and hole injection of an aluminium gallium nitride (AlGaN) barrier [Zabu Kyaw, Appl. Phys. Lett., vol104, p161113, 2014]. The team consisted of researchers from Nanyang Technological University, Singapore; Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), Singapore; and Bilkent University, Turkey.

AlGaN barriers are commonly used in GaN-based LEDs to avoid electron overflow into the p-contact region. Electron overflow tends to lead to non-radiative recombination and hence reduced efficiency. However, AlGaN electron-blocking layers (EBLs) also raise a barrier to hole injection that again reduces efficiency.

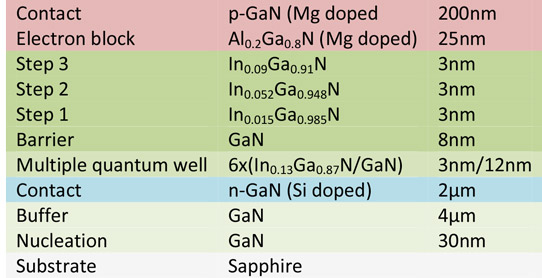

The LED epitaxial material was grown on sapphire using metal-organic chemical vapor deposition (MOCVD). The device structure (Figure 1) included a three-step InGaN tailored LQB between the multiple quantum well (MQW) active light-emitting region and the electron-blocking layer. A reference device was also produced where the tailored LQB was replaced with 17nm of GaN.

Figure 1: Epitaxial structure of LED with 3-step InGaN tailored last quantum barrier.

The epitaxial material was fabricated into 350μmx350μm mesa LEDs. A transparent conducting layer of nickel/gold was deposited on the p-contact layer. The contact pads for both the p- and n-type layers consisted of titanium/gold.

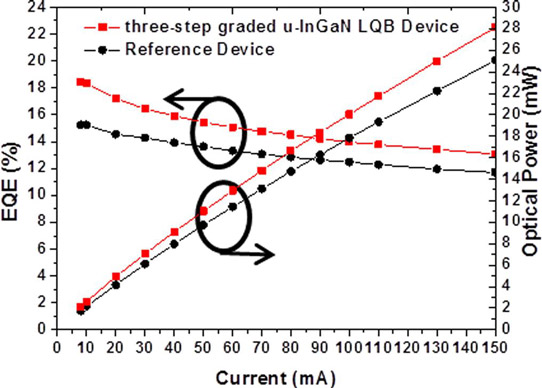

The use of a tailored LQB improved both external quantum efficiency (EQE) and output power (Figure 2). At 150mA injection current, the output power of the tailored LQB LED of 28.13mW was 12.25% higher than that for the plain GaN LQB device of 25.06mW. The EQE improvement was 11.98% at the same current injection.

Figure 2: Optical output power and EQE versus current injection for reference and three-step graded u-InGaN LQB devices.

The researchers comment: “This observed improvement of the optical power and the EQE is well attributed to the simultaneous reduction of the electron overflow and enhancement of the hole injection efficiency enabled by the proposed three-step u-InGaN LQB.”

Table 1: Energy barrier heights computed for reference and three-step graded u-InGaN LQB devices at 20A/cm2.

| Device | LQB electron barrier | EBL electron barrier | EBL hole barrier |

| Reference | 210meV | 325meV | 469meV |

| Three-step graded u-InGaN LQB | 362meV | 490meV | 358meV |

Simulations suggest that one factor reducing electron overflow is an increased effective potential barrier for electrons of the LQB of 362meV in the tailored LQB LED at 20A/cm2 injection, compared with 210meV for the all-GaN LQB device. The simulations also suggest enhanced electron blocking by the EBL itself and better hole injection with tailored LQB due to an increased barrier for electrons and a reduced barrier for holes (Table 1).

http://dx.doi.org/10.1063/1.4873395

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.