- News

1 October 2014

Airlight and IBM partner to commercialize HCPVT solar system by 2017

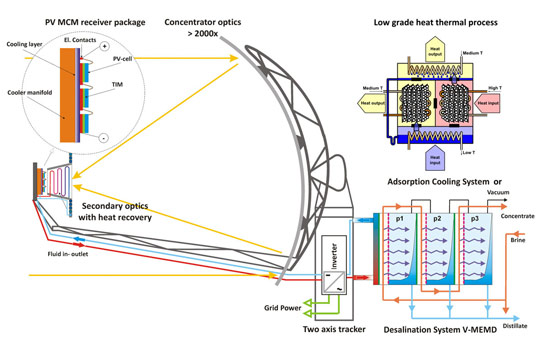

Airlight Energy of Biasca, Switzerland, which supplies proprietary technology for large-scale production of electricity using solar power and for energy storage, has partnered with IBM Research, aiming to bring affordable solar technology to market by 2017. The high-concentration photovoltaic thermal (HCPVT) system can concentrate the sun’s radiation 2000 times and convert 80% of it into useful energy to generate 12kW of electrical power and 20kW of heat on a sunny day (enough to power several average homes).

The 10m-high system uses a 40m2 parabolic dish made of patented fiber-based concrete, which can be molded into nearly any shape in less than 4 hours and has mechanical characteristics similar to those of aluminium at one-fifth the cost, it is reckoned.

The inside of the parabolic dish is covered with 36 elliptic mirrors made of 0.2mm-thick recyclable plastic foil with a silver coating, which are then curved using a slight vacuum. The mirrored surface area concentrates the sun’s radiation by reflecting it onto several micro-channel liquid-cooled receivers, each of which is populated with a dense array of multi-junction photovoltaic chips. Each 1cm × 1cm chip produces electrical power of up to 57 watts on a typical sunny day. To protect them from rain or dust, the mirrors and the receiver are encased with a large inflated transparent plastic enclosure, which also prevents birds and other animals from getting in harm’s way.

The photovoltaic chips, similar to those used on orbiting satellites, are mounted on micro-structured layers that pipe treated water within fractions of millimeters of the chip to absorb the heat and draw it away 10 times more effectively than with passive air cooling. The 85-90°C hot water maintains the chips at safe operating temperatures of 105°C, which otherwise would reach over 1500°C. The entire system sits on a tracking system that positions the dish at the best angle throughout the day to capture the sun’s rays. The direct hot-water cooling design with very small pumping power has already been made commercially available by IBM in its high-performance computers, including SuperMUC (Europe’s fastest supercomputer) in 2012. “The direct cooling technology with very small pumping power used to cool the photovoltaic chips with water is inspired by the hierarchical branched blood supply system of the human body,” says Dr Bruno Michel, manager, advanced thermal packaging at IBM Research.

Picture: Schematic of HCPVT system.

An initial demonstrator of the multi-chip solar receiver was developed in a previous collaboration between IBM and the Egypt Nanotechnology Research Center. With such a high concentration and based on its radical design, researchers believe that with high-volume production they can achieve a cost of 2-3 times lower than comparable systems.

To market, license and sell the HCPVT system globally, Airlight Energy has spun off the new company Dsolar (dish solar), which has licensed several patents from IBM in the area of hot-water chip cooling. “Not only is the system affordable, but it will create jobs where it is installed because many of the materials will be sourced locally,” says Dr Gianluca Ambrosetti, Airlight Energy’s head of research, with responsibilities for building the new spinoff. “We expect to partner with firms around the world to bring a commercial version to market by 2017,” he adds.

Based on its current design, scientists estimate that the operating lifetime for the HCPVT structure is up to 60 years with proper maintenance. The protective foil and the plastic elliptic mirrors will need to be replaced every 10–15 years depending on the environment, and the PV cells need replacing every 25 years. Throughout its lifetime the system will benefit from design and manufacturing improvements, allowing even greater system efficiency, the firm reckons.

The HCPVT system can also be customized with further equipment to provide drinkable water and air conditioning from its hot water output. For example, salt water can pass through a porous membrane distillation system, where it is vaporized and desalinated.

Airlight and the IBM Corporate Service Corps (CSC) aim to team up to donate an HCPVT system to two deserving communities. Each winning community will receive a prototype HCPVT system from Airlight, and be eligible for pro bono enablement and transformation support from IBM CSC. Applications from communities will be open in 2015 and the winners will be announced in December 2015, with installations beginning in late 2016.

Airlight and IBM envision the HCPVT system providing energy to locations around the world including southern Europe, Africa, the Arabian peninsula, the southwestern part of North America, South America, Japan and Australia. In addition to residences, additional applications include remote hospitals, medical facilities, hotels and resorts, shopping centers and locations where available land is at a premium.

Some of the initial funding for the development of the HCPVT system was provided to IBM Research, Airlight Energy, ETH Zurich and the Interstate University of Applied Sciences Buchs NTB (Institute for Micro- and Nanotechnology MNT) in a three-year $2.4m (CHF2.25m) grant from the Swiss Commission for Technology and Innovation.

Swiss funding for IBM-led collaboration to develop high-concentration photovoltaic thermal system

www.ibm.com/ibm/responsibility/corporateservicecorps/solar.html

www.research.ibm.com/labs/zurich/dsolar