- News

4 March 2015

ROHM's SiC MOSFETs used in ultra-high-voltage pulse generators

ROHM of Kyoto, Japan says that its SCT2080KE silicon carbide (SiC) MOSFET has been adopted in the new SiC-Pulser Series of ultra-high-voltage pulse generators launched by Japan's Fukushima SiC Applied Engineering Inc.

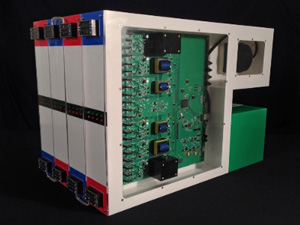

Picture: Fukushima SiC Applied Engineering's ultra-high-voltage pulse generator.

Picture: Fukushima SiC Applied Engineering's ultra-high-voltage pulse generator.

Pulse generators are used in applications including high-voltage accelerators, plasma generators, and laser processing machines. Conventional systems utilize silicon devices or vacuum tubes as switching elements. However, this often entails a large number of system components, which often results in enormous construction and installation costs.

In contrast, SiC switching elements combine high breakdown voltage with very low on-resistance and high-speed switching performance. ROHM says that, by adopting its SiC devices in the switch module, pulse generators can be made considerably smaller and provide a level of performance that cannot be achieved with conventional systems.

"We evaluated a number of different switching elements," says Fukushima SiC Applied Engineering's president Kokubo. "As a result, we determined that ROHM's SiC MOSFET was able to meet our criteria for reliability and performance. This marks the world's first practical application of SiC in a pulse generator," he adds. "For example, when trying to achieve a normal conducting linac (linear accelerator) with a beam output on the order of tens of kW, conventional vacuum tube acceleration technology will result in a linac that is 1600m long. However, by adopting SiC-based acceleration technology we can reduce the length of the linac to less than 6m, thereby decreasing construction and installation costs significantly."

Since the March 2011 Tohoku earthquake, Fukushima SiC Applied Engineering is "supporting reconstruction by implementing build-to-order manufacturing of advanced power electronics products using these SiC devices at the Fukushima facility," says Kokubo. "Going forward, we would like to work together to expand the possibilities of SiC to a variety of fields."

Picture: Rohm's SiC MOSFET.

Picture: Rohm's SiC MOSFET.

ROHM is ramping up production of SiC products, specifically for the power sector. The SCT2080KE SiC MOSFET reduces switching losses by more than 70% compared with silicon IGBTs used in general inverters, the firm claims. Support for higher switching frequencies allows the use of smaller peripheral components, contributing to end-product miniaturization. SiC devices are already employed in converters and inverters in industrial equipment and power conditioners in solar power systems, and ROHM is exploring new markets for SiC devices.

The power device field is a key area for continued growth and ROHM aims to continue to strengthen its lineups of both silicon and SiC solutions to meet current and future demand.

ROHM launches 80milliOhm 1200V SiC MOSFETs; one with co-packaged anti-parallel SiC Schottky

ROHM Semiconductor SiC Schottky barrier diodes SiC power MOSFET

www.rohm.com/web/global/products/-/product/SCT2080KE