- News

26 October 2015

FBH uses LayTec's EpiTT Gen3 metrology tool for high-temperature MOCVD growth of AlN/sapphire templates for UV LEDs

In the course of its cooperation with in-situ metrology system maker LayTec AG of Berlin, Germany in the consortium 'Advanced UV for Life', the group of professor Markus Weyers at Berlin-based Ferdinand-Braun-Institut, Leibniz-Institut für Höchstfrequenztechnik (FBH) has developed a high-temperature (HT) metal-organic chemical vapor deposition (MOCVD) process for growing low-defect-density aluminium nitride (AlN)/sapphire templates for ultraviolet light-emitting diodes (UV LEDs).

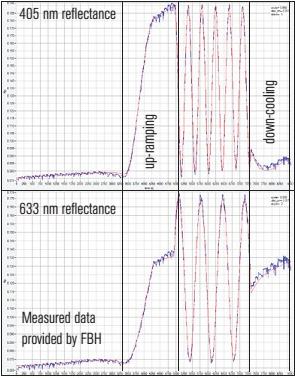

Picture: Two-step growth of AlN template structure for UV LEDs monitored by EpiTT Gen3 during AlN growth run in a modified HT Aixtron G3 Planetary reactor (950nm reflctance not shown).

Picture: Two-step growth of AlN template structure for UV LEDs monitored by EpiTT Gen3 during AlN growth run in a modified HT Aixtron G3 Planetary reactor (950nm reflctance not shown).

Splitting UV LED growth into two separate steps in two different MOCVD systems completely avoids the possible memory-effect-related interference of aluminium gallium nitride (AlGaN) processes with the growth of high-quality AlN buffers.

This UV LED buffer growth (see Figure) is monitored by three-wavelength reflectance, improved for very thick AlN/AlGaN layer stacks, and by emissivity-corrected high-temperature sensing of LayTec's EpiTT Gen3 tool. The blue curve is the result of quantitative analysis of three-wavelength reflectance measured by EpiTT Gen3. The thickness of the AlN nucleation layer is determined from the fitting curves (red) to be 43.2±0.2nm, and the AlN HT buffer layer thickness to be 524.2±0.5nm. The consistency of the HT nk database that was employed is also obvious from the good agreement of the simulated curve segments in the temperature ramp-up and cool-down steps.

LayTec says that the key to the EpiTT Gen3 HT performance is not just the widened temperature sensing range but, most importantly, also the HT nk database (up to 1500°C) for the AlN and AlGaN class of materials as well as improved performance for double-side polished sapphire wafers.

LayTec Metrology MOCVD UV LEDs AlGaN