- News

23 September 2015

Slanted trench approach to side-mode suppression in Fabry-Perot laser diodes

Researchers based in China and Canada have developed single-mode ridge waveguide Fabry-Perot (RW FP) laser diodes using a pair of etched trenches that are slanted to reflect out unwanted wavelengths [Xun Li et al, Appl. Phys. Lett., vol107, p091108, 2015]. Side-mode suppression ratios (SMSRs) up to 35dB were achieved.

The team from Huazhong University of Science and Technology in China, McMaster University in Canada, and Shandong University in China comment: "As a cost-effective solution, this device is promising as a replacement for conventional distributed feedback laser diodes in specific applications where single-mode operation is indispensable but precise control of the lasing wavelength and/or very high SMSR (e.g. >40 dB) are not required."

Standard FP laser diodes can be mass produced, but suffer from multi-mode operation. This creates noise problems in high-speed moderate-span passive optical networks. Cleaning up the emission spectrum with distributed feedback techniques suffers from low manufacturing yields, increasing cost.

The etched-trenches create a coupled cavity that acts as an extra band-pass filter (BPF), while the slanting ensures that other modes do not compete with the selected mode inside the laser cavity.

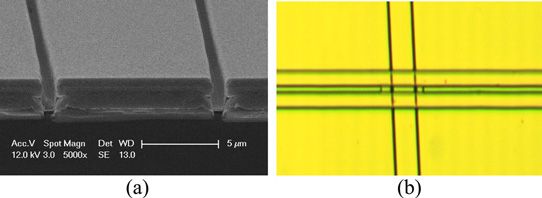

The researchers fabricated 1310nm ridge-waveguide Fabry-Perot lasers using strained-layer indium aluminium gallium arsenide/indium phosphide (InAlGaAs/InP) multiple quantum well material. Based on simulations, a pair of deep trenches were etched into the structure (Figure 1). The optimum trench design was for 1.1μm width with 10μm separation at 4° slant. The researchers found that varying the trench parameters allowed them to lock into one of the many FP modes so that precise control of this aspect of the fabrication was not required.

Figure 1: (a) Cross-sectional and (b) top views of trenches in fabricated device.

The FP cavity length was 250μm. The devices were packaged in standard transistor outline packages without cooling.

In theory, the trenches should be as deep as possible to suppress side-modes, but the researchers were concerned about reliability issues and limited the depth to the etch-stop layer used for the ridge etching. The researchers add: "As such, the crossing trenches can be formed in the same step as the ridge waveguide itself, so that no extra burden is introduced to the conventional RW FP laser fabrication process other than the replacement of the mask pattern in the standard photolithography process."

The 12-13μm region around the trenches was not metalized so that the band-pass filter region was passive. This was to avoid the laser wavelength and side-mode suppression ratio being affected by conditions such as the bias current.

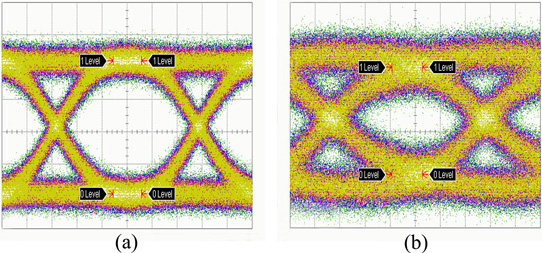

In testing, the devices were directly modulated at 2.5 gigabits per second and 6.25Gbps with a 231 pseudo-binary sequence. The modulated laser light was sent down 50km of standard single-mode fiber (Figure 2). With a 10Gbps signal, the researchers claim that the reception demonstrated "clear eye opening" even after 10km travel.

Figure 2: Measured eye-diagrams after 50km standard single-mode fiber transmission at modulation speeds of (a) 2.5Gbps and (b) 6.25Gbps.

The researchers report that aging tests at 100°C and 100mA current have reached 3000 hours, showing no appreciable degradation.

The yield for devices with side-mode suppression ratio greater than 20dB exceeded 55%. For 30dB SMSR, the yield was better than 30%. Single-mode lasers based on distributed feedback usually have yields less than 30% for 30dB SMSR.

The researchers comment: "When the reliability issue related to Al oxidization is eliminated by advanced processing technologies, or by using Al-free (InGaAsP/InP) SL-MQW laser diodes, the trenches can then be etched further through the active region, and our simulations show that the yield can be increased further to more than 70%."

The threshold current was around 12mA and the slope efficiency 0.2mW/A from a single facet.

Fabry-Perot laser diodes InAlGaAs InGaAsP InP

http://dx.doi.org/10.1063/1.4930027

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.