- News

1 December 2016

Continuous-wave room-temperature broad-area quantum cascade lasers

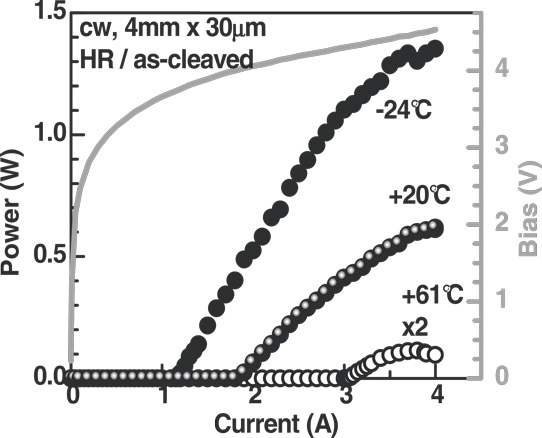

Two researchers at Humboldt University Berlin in Germany have developed broad-area quantum cascade lasers (QCLs) that can operate in continuous-wave mode beyond 100°C [M. P. Semtsiv and W. T. Masselink, Appl. Phys. Lett., vol109, p203502, 2016]. The emission wavelength was 4.6μm. One device achieved an output power of 1.3W at -27°C and 0.6W at +20°C.

QCLs are the leading semiconductor laser sources being developed for the mid- to far-infrared spectral regions. Although QCLs with wavelengths ranging from a couple of microns to hundreds of microns have been reported, the best performance comes in the mid-infrared (4-10μm). Pulsed operation is easier to achieve, since the active region does not accumulate heat that raises the effective temperature.

Continuous wave (cw) operation is needed for applications that require very narrow spectral width such as high-resolution spectroscopy. Further, cw operation allows for higher average power output, as is needed for infrared counter-measures against heat-seeking missiles.

In order to achieve cw performance with high power at room temperature, QCLs are produced with large numbers of cascades of between 30 and 40, along with a medium stripe width up to 16μm. Such devices depend on vertical and lateral heat flow to keep active-region temperatures down.

The approach of Semtsiv and Masselink was to reduce the number of cascades, allowing for wider stripes. Reducing the number of cascades in the active region reduced the heat generation, allowing for only the vertical dissipation that dominates in wide stripes.

The QCL material was grown on lightly sulfur-doped indium phosphide (n-InP) by molecular beam epitaxy (MBE). The substrate also served as bottom cladding for the laser cavity. The epitaxial layers consisted of a 360nm InGaAs bottom spacer, a 10-period InGaAs-InAlAs active region, a 360nm InGaAs top spacer, and a 4μm InP top cladding. The active region had a strain-compensated design.

Broad 30μm-wide ridges were formed with wet etching. The sidewalls were covered with 600nm reactive magnetron sputtering silicon dioxide insulation. Contacts were made with chromium and gold. A heat spreader was formed with a 5μm-thick layer of galvanic gold over-coating.

The laser stripes were soldered epi-side down using semi-eutectic gold-tin on aluminium nitride submounts. A 1mm-wide and 30μm-thick copper foil was soldered to the back-side of the InP substrate as a contact.

Lasers with 4mm-long cavities and as-cleaved facets had a pulse-mode threshold current density of 2kA/cm2 at room temperature. The power/wall-plug efficiency was 6% at 8kA/cm2. Room-temperature QCLs have achieved power efficiency up to 28% in pulsed mode.

Figure 1: (Grey line) Current-voltage characteristic at +20°C and (symbols) current-power characteristics at indicated temperatures for 4mm-long one-side HR-coated QCL stripe in cw mode.

The threshold was reduced to 1.2kA/cm2 by coating the back-facet with a high-reflectance (HR) coating of silicon dioxide, chromium and gold (Figure 1). The coating also allowed continuous-wave operation at room temperature with threshold power density of 6kW/cm2 (1.5kA/cm2x4V).

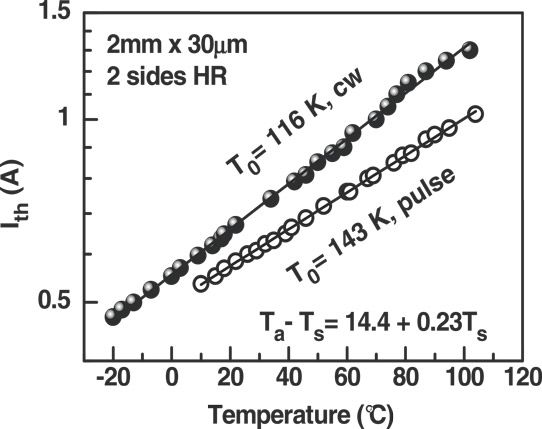

Further threshold reduction in continuous-wave operation to 3.4kW/cm2 threshold power density (3.8Vx0.9kA/cm2) was seen by coating both facets with the same silicon dioxide, chromium and gold layers with different thicknesses designed to give high- and semi-reflective properties. This two-sided coating device was 2mm long.

Figure 2: Threshold current density, Jth, versus heat-sink temperature for two-side HR-coated 30μmx2mm laser driven with 100ns current pulses (open symbols) and with constant current (full symbols). Solid lines are the exponential fit used to determine characteristic temperature T0.

Using temperature-dependent measurements the researchers estimate the thermal conductance of the device at 240K to be 235W/K-cm2 and at 375K to be 140W/K-cm2. These values were consistent with a predicted value of 229W/K-cm2, calculated using a model with one-sided heat flow in the region 9°C to 26°C. The researchers comment: "This strongly indicates asymmetric heat flow in our QCL, which is rather consistent with the manner in which our QCLs were mounted. This result promises, in turn, a significant improvement in performance by improving the heat removal at the top electrical contact."

The researchers operated the devices up to 102°C in continuous mode.

The team comments: "This demonstration opens an appealing route for almost unlimited cw power scaling by increasing the laser ridge width. For achieving high brightness in cw mode, this approach has to be combined in future with existing optical-mode-control solutions."

QCL n-InP MBE InGaAs InGaAs-InAlAs InGaAs

http://dx.doi.org/10.1063/1.4967834

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.