- News

18 August 2017

Monolithic red-green-blue InGaN pixels from strain engineered nanopillars

University of Michigan in the USA has used local strain engineering of nanopillars to produce light-emitting diode (LED) red-green-blue (RGB) subpixel arrays based on indium gallium nitride (InGaN) multiple quantum wells (MQWs) [Kunook Chung et al, Appl. Phys. Lett., vol111, p041101, 2017].

The researchers comment: “The proposed nanopillar LED devices can potentially provide a practical path for the future LED based microdisplay technology, especially aimed for augmented reality applications.”

Such displays need high brightness, contrast, resolution, power efficiency, and device lifetime. These requirements can’t be met by present-day liquid crystal or organic LED display technologies.

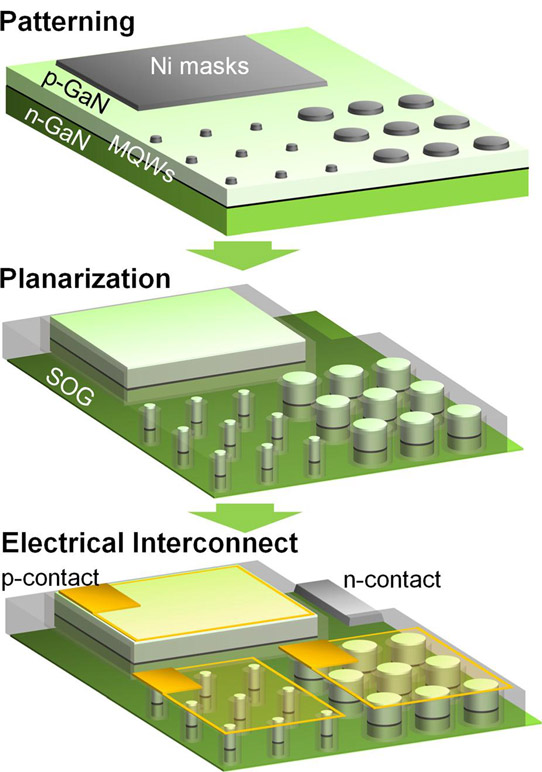

Figure 1. Schematic of fabrication process for RGB LED pixel, which includes three steps: subpixel patterning, sample planarization, and formation of electrical interconnects.

Also key for microdisplays is color mixing capability. The researchers note that despite there being a range of monolithic RGB LED technologies, usually based on InGaN, color mixing has not yet been demonstrated.

The team explains: “Color mixing is one of the key elements for any display technology. It requires independent and linear control of the intensity from each color channel. At the same time, the color coordinates of these color channels must remain stable.”

Metal-organic chemical vapor deposition (MOCVD) on 2-inch c-plane sapphire substrate produced a five-period multiple quantum well InGaN/GaN structure. The indium composition and well thickness were designed to produce red photoluminescence with wavelength longer than 600nm. Above the MQW structures were added a 20nm aluminium gallium nitride (Al0.2Ga0.8N) electron-blocking layer and a p-GaN contact layer.

Color variations in pixels were induced by local strain engineering (Figure 1). Nanopillars of varying diameters were fabricated to relax strain in the heterostructures: 150nm for green light, and 50nm for blue. Red light came from pixels using the thin-film material as-grown. The nanopillar and other patterning was achieved using nickel masks. The nanopillars were separated by 300nm in both cases.

RGB balancing was achieved by creating different sub-pixel areas: 400μmx400μm for red, 341NPsx341NPs for green, and 434NPsx434NPs for blue. The subpixels were separated by 150μm. The areas of the respective active regions were 160,000μm2, 2050μm2, and 370μm2.

The larger area for the more strained, longer-wavelength subpixels compensates for the efficiency reduction caused by the quantum-confined Stark effect, where charge polarization of the III-nitride bonds creates an electric field that tends to inhibit electron-hole recombination into photons. The electric field is increased by strain due to piezoelectric effects.

The uncooled pixels were driven with pulse-width modulation (PWM) from a Arduino microcontroller circuit. Controlling output intensity with PWM avoids wavelength shifts that arise in continuous wave operation at different current injection levels (quite apart from self-heating effects).

The bias voltages were optimized to balance the RGB output powers, starting with the red subpixel. In microdisplay applications, it would be preferred to have one bias voltage across the device. This could be achieved by suitably tuning the active region areas.

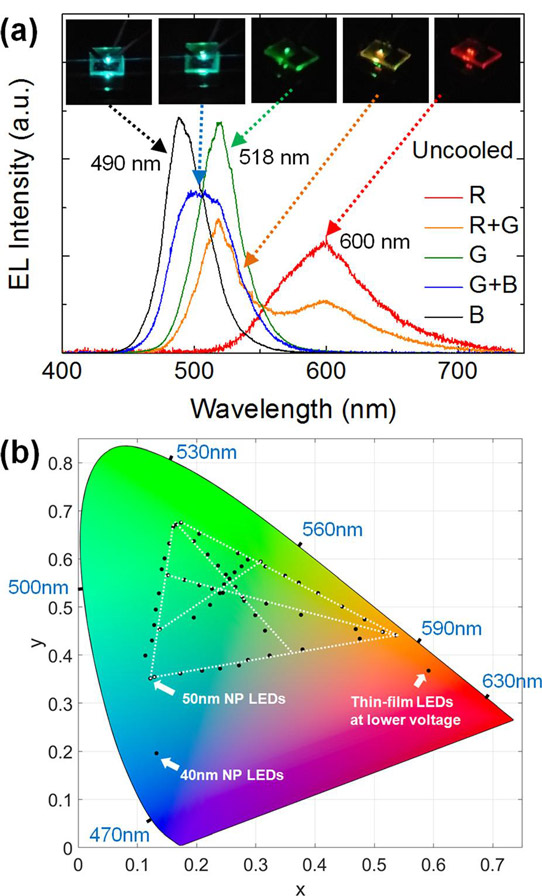

Figure 2.(a) Electroluminescence (EL) spectra and corresponding images. (b) Each EL spectrum converted into set of CIE-1931 color coordinates. White dotted lines correspond to theoretical color mixing results expected from two end points, i.e. with one or two color channels off for case of two- and three-color mixing, respectively. Also shown are color coordinates of LED devices on the same sample which were not used in the color mixing experiment due to insufficient output power.

Each subpixel had a dominant wavelength, respectively, at 490nm (blue), 518nm (green), and 600nm (red). The set up enabled production of cyan, mixing blue and green, and yellow, mixing green and red (Figure 2).

Although the color gamut was more restricted than needed for full-color display applications, the device showed good linearity, indicating minimal crosstalk between the pixels. The researchers add that “with further improvements of the epitaxial growth and optimization of the electrical properties for small-diameter nanopillar devices, it is expected that the color gamut can approach a typical organic LED display.”

Another improvement would be to extend the base wavelength of the InGaN MQW out to 650nm.

http://dx.doi.org/10.1063/1.4995561

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.