- News

14 February 2017

Aluminium indium gallium nitride electron-blocking layers

South China University of Technology and Taiyuan University of Technology in China have used quaternary aluminium indium gallium nitride (AlInGaN) semiconductor alloys to improve the performance of electron-blocking layers (EBLs) in blue light emitting diodes (LEDs) [Zhiting Lin et al, IEEE Transactions on Electron Devices, vol64, p472, 2017].

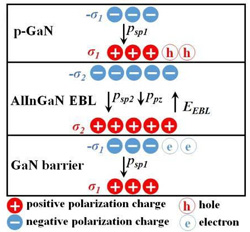

Conventional AlGaN EBLs aim to stop electrons overshooting the active light-emitting region and recombining non-radiatively in the p-type GaN contact layers. However, AlGaN EBLs also reduce hole injection and suffer from strain-induced piezoelectric fields from charge-polarization effects of the III-nitride chemical bond. The piezoelectric field acts to reduce the barrier to electron flow.

Figure 1: Illustration of polarization charge distribution for sandwich structure composed of p-GaN, AlInGaN EBL, and GaN barrier.

Figure 1: Illustration of polarization charge distribution for sandwich structure composed of p-GaN, AlInGaN EBL, and GaN barrier.

The researchers used AlInGaN to reduce the strain and hole blocking effects of the EBL (Figure 1) both in simulations and experimental work. Test vehicles of simulations were grown on 2-inch c-plane sapphire by metal-organic chemical vapor deposition (MOCVD). The AlInGaN was grown at 760°C at 200hPa (20kPa) pressure. The composition was varied through altering the trimethyl-indium flow. The material was divided into standard 750μmx220μm LED chips.

A reference EBL (LED A) had Al0.15Ga0.85N composition. Four AlxInyGa1-x-yN quaternary EBL structures were also produced with 0.35 Al-content, and 0.04, 0.11, 0.18, 0.21 In-content for LEDs B-E in order, spanning In/Al ratios of 0.1 to 0.6.

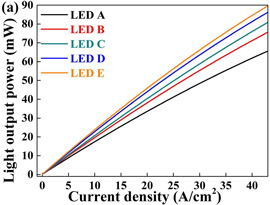

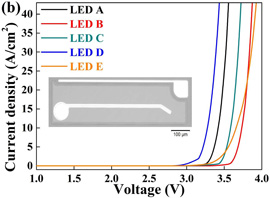

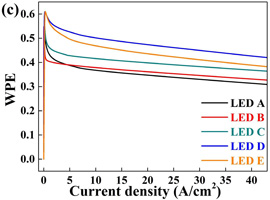

Figure 2: (a) Experimental LOP versus current density curves and (b) current density versus voltage curves for LEDs A–E. Inset: optical microscope image of LED chip. (c) Experimental WPE of LEDs A–E with current density ranging from 0A/cm2 to 43A/cm2.

The light output power (LOP) from the devices A-E at 43A/cm2 was 65.90mW, 75.99mW, 81.26mW, 86.58mW and 90.07mW, respectively (Figure 2). In particular, the improvements of LEDs D and E over that of LED A were 31.38% and 36.68%, respectively.

However, LED D had better performance in terms of lower forward voltage for a given current, which indicates greater power efficiency. At 14.4A/cm2 (20mA) injection, the forward voltages for LEDs A-E were 3.45V, 3.77V, 3.62V, 3.31V and 3.72V, respectively.

The improved overall performance of LED D was reflected in it having the best peak wall-plug efficiency (WPE) of 60.99% and lowest efficiency droop of 31.12% at 43A/cm2. The corresponding WPEs for LEDs A-C and E were 51.58%, 54.78%, 57.58% and 58.84%; the respective droops were 40.12%, 40.33%, 36.83% and 35.02%.

The 0.5 In/Al ratio of LED D giving the best performance supported the results of the researchers' simulations. The team explains that, according to their simulations, increasing the In/Al ratio enhances carrier injection efficiency, increasing internal quantum efficiency (IQE) and hence WPE. However, beyond 0.35 In/Al ratio, carrier injection efficiency approaches saturation at 100%. High In/Al fractions also increase series resistance of the EBL layer, increasing forward voltage and hitting WPE, as seen in LED E.

The researchers admit that the experimental work does not exactly match the performance expected from the simulation – this is attributed to relatively poor AlInGaN material due to the large difference in optimal growth temperature of the AlGaN (~1000°C) and InGaN (700-800°C) components.

The researchers chose a low growth temperature to encourage indium incorporation, but at the cost of AlGaN quality. "As a result, the material issues in the AlInGaN quaternary alloy, such as phase separation, composition inhomogeneity, and relatively poor crystalline quality, will deteriorate the positive influence from the AlInGaN EBL, especially for the condition of high Al and In fractions," the team writes.

https://doi.org/10.1109/TED.2016.2637407

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.