- News

11 January 2017

Purdue demos potential of beta gallium oxide on insulator transistor for ultra-efficient switches in power electronics

Purdue University has demonstrated the high-performance potential of an experimental transistor made of beta gallium oxide, which could bring new ultra-efficient switches for applications such as the power grid, military ships and aircraft (Hong Zhou et al, 'High Performance Depletion/Enhancement-Mode β-Ga2O3 on Insulator (GOOI) Field-effect Transistors with Record Drain Currents of 600/450mA/mm', IEEE Electron Device Letters, vol38 (2017), no1, p103).

The semiconductor is promising for the next generation of power electronic devices needed to control the flow of electrical energy in circuits. Such a technology could help to reduce global energy use and greenhouse-gas emissions by replacing less efficient and bulky power electronics switches now in use.

The gallium oxide on insulator (GOOI) field-effect transistor is especially promising because it has an ultra-wide bandgap (needed for switches in high-voltage applications). Compared with other semiconductors, devices made from β-Ga2O3 have a higher breakdown voltage, says Peide Ye, Purdue University's Richard J. and Mary Jo Schwartz Professor of Electrical and Computer Engineering.

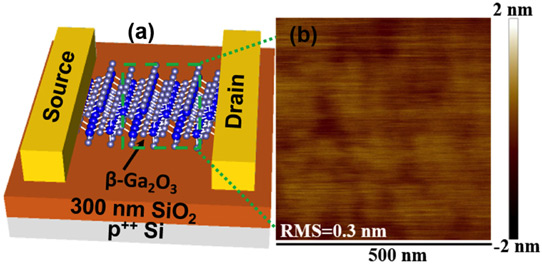

Picture: Left: Schematic showing the design for an experimental transistor made of beta gallium oxide. Right: an atomic force microscope image of the semiconductor. (Purdue University image/Peide Ye).

The team also developed a new low-cost method using adhesive tape to peel off layers of β-Ga2O3 from a single crystal, representing a far less expensive alternative to epitaxy. The market price for a 1cm x 1.5cm piece of β-Ga2O3 produced using epitaxy is about $6000. In comparison, the Scotch-tape approach costs pennies and can be used to cut films of β-Ga2O3 into belts or nano-membranes, which can then be transferred to a conventional silicon disc and manufactured into devices, Ye says.

The technique was found to yield extremely smooth films, with a surface roughness of 0.3nm. This is another factor that bodes well for its use in electronic devices, says Ye, who is affiliated with the NEPTUNE Center for Power and Energy Research, funded by the US Office of Naval Research and based at Purdue's Discovery Park (in the Birck Nanotechnology Center). Related research was supported by the center.

The Purdue team achieved electrical currents 10-100 times greater than other research groups working with β-Ga2O3, Ye reckons.

One drawback of the material is that it has poor thermal properties. To help solve the problem, future research may include work to attach the material to a substrate of diamond or aluminum nitride (AlN).

Ga2O3 Gallium oxide transistors

http://ieeexplore.ieee.org/document/7765124