- News

13 October 2017

Low-threshold indium arsenide quantum dot laser diodes on silicon

University of California Santa Barbara (UCSB) in the USA claims record low threshold currents for indium arsenide (InAs) quantum dot (QD) laser diodes (LDs) grown on silicon (Si) [Daehwan Jung et al, Appl. Phys. Lett., vol111, p122107, 2017]. The team says further that the 6.7mA threshold achieved is the lowest for any kind of Fabry-Perot laser grown on silicon. The use of QDs ameliorates problems arising from threading dislocations in lattice-mismatched crystal structures on silicon.

Combined with silicon photonics (waveguides, etc), the researchers see potential for a monolithically integrated, efficient light source to power high-performance, chip-scale optical interconnects to meet growing demand for data bandwidth.

The researchers used on-axis (001) gallium phopshide (GaP) on Si substrates, which are available commercially from NAsPIII/V GmbH in diameters up to 300mm. Although miscut off-axis silicon enables gallium arsenide (GaAs) to be grown directly without anti-phase domains, on-axis substrates are preferred for manufacturing in standard CMOS processing foundries. GaP has been found to terminate anti-phase domains within 40nm of the silicon interface.

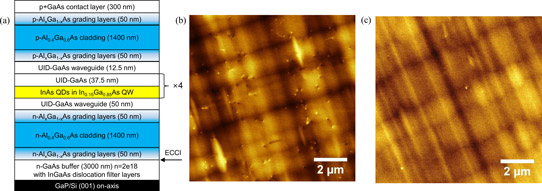

Figure 1: (a) Cross-sectional schematic of InAs QD laser structure grown on GaP/Si substrate. (b) Electron channeling contrast images showing threading dislocations before and (c) after optimization of GaAs/GaP/Si template.

Solid-source molecular beam epitaxy was used to create a 3μm GaAs buffer (Figure 1). The buffer growth included four cycles of thermal annealing between 320°C and 700°C under arsenic over-pressure to annihilate dislocations. A 500°C superlattice dislocation filter in the form of 10 layers of In0.1Ga0.9As was further inserted into the buffer layer. The filter reduced surface roughness from 5.45nm root-mean-square to 2.48nm, according to atomic force microscopy (AFM).

Electron channeling contrast imaging (ECCI) measurements suggested that threading dislocation densities (TDDs) were reduced by a factor of 20 to 7.3x106/cm2, compared with a non-optimized buffer.

The laser diode structure was completed with molecular beam epitaxy. The active QD region was grown at 495°C, producing 2.55 monolayer InAs dots in 7nm InGaAs wells. The bottom separate-confinement heterostructures were grown at 580°C, while the top half of the structure was grown at 560°C.

A separate single-layer InAs QD sample designed for photoluminescence analysis showed a peak at 1285nm. “The full-width at half-maximum is ~28meV, indicating an excellent QD size homogeneity,” the researchers add. AFM analysis suggested a QD density of ~5.2x1010/cm2, similar to what is seen in InAs QDs on pure GaAs substrate. The QDs were found to have an excited state 84meV above the ground state.

Ridge-waveguide laser diodes were fabricated with the cavity lengths defined by cleaving after wafer thinning to 150-200μm thickness. A 1485μmx2.5μm device had a threshold current of 9.5mA in continuous-wave operation. The researchers say that this is significantly lower than for previous on-axis and miscut QD-based laser diodes on silicon. “We believe that the significant threshold reduction is attributed to the increased internal quantum efficiency in the devices grown on the low-TDD GaAs templates,” they write.

The output power reached more than 71mW per facet for ground-state lasing. Excited-state lasing began at 400mA. The lasing wavelength was initially at 1270nm, with more Fabry-Perot longitudinal lasing modes kicking in as the current increased to 15mA.

A 2600μmx8μm laser diode reached an output power of 175mW with 27.5mA threshold (132A/cm2). The wall-plug efficiency (WPE) was 29.5% at 175mA. Ground-state lasing continued up to 80°C with ~7mW output.

The researchers comment: “This demonstrates that the QD lasers on GaP/Si can operate in a harsh environment such as those found in data-center and high-performance computing applications.”

The device had a low characteristic temperature for the threshold of 32K, indicating rapid thermal fall-off of performance, but the researchers hope that p-modulation doping in the active region will improve temperature characteristics.

The as-cleaved devices had a minimum threshold current density of 147A/cm2 at 20°C, lower than the previously reported value of ~425A/cm2 from high-reflectivity-coated QD lasers grown on on-axis (001) silicon substrates. The researchers attribute the low threshold to “the high-quality GaAs template with low TDD in addition to the low transparency current from using a reduced number of QD layers (four instead of five to seven) in the active region”.

The highest WPE was 38.4% at 74mA from a 1366μmx4μm QD laser. The output power of the device was 18.6mW. There was a wide range of WPEs and output powers achieved due to fabrication non-uniformities and imperfect wafer cleaving.

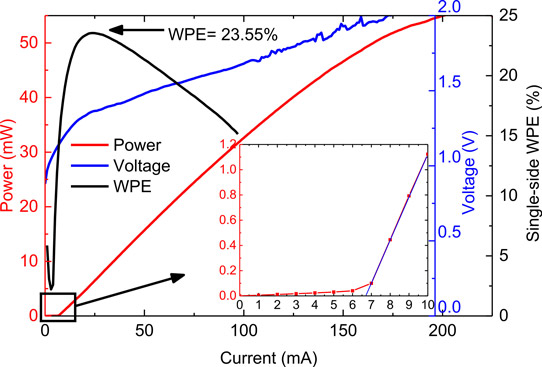

Figure 2: Single-side CW light output power-current-voltage LIV and wall-plug efficiency curves from a 1090μmx3μm laser with one 95% HR-coated facet. Inset: continuous-wave threshold current of 6.7mA at 20°C.

Coating of one facet with 95% high-reflectivity (HR) structures consisting of layers of tantalum oxide and silicon dioxide was carried out on a 1090μmx3μm device. The threshold current was 6.7mA (Figure 2). The researchers comment: “We believe that this value is the lowest threshold current density to date for any kind of Fabry-Perot lasers on Si substrates. Its corresponding threshold current density is 205A/cm2, and the maximum single-side WPE is 23.55%.”

InAs quantum dot laser diodes InAs Laser diodes Si substrates GaAs

http://dx.doi.org/10.1063/1.4993226

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.