- News

10 September 2018

Presto extends test capabilities to 100GHz and beyond

© Semiconductor Today Magazine / Juno PublishiPicture: Disco’s DAL7440 KABRA laser saw.

In booth B245 at European Microwave Week (EuMW 2018) in Madrid, Spain (23-28 September), Presto Engineering Inc of San Jose, CA, USA – which provides outsourced operations to semiconductor and Internet of Things (IoT) device firms (including developing industrial solutions for RF, analog, mixed-signal and secured applications, from tape-out to delivery of finished goods) – is highlighting that it can now provide high-volume testing of semiconductor devices up to 100GHz and beyond.

Applications that use GHz frequencies, i.e. millimeter wavelengths (mmW), are increasing rapidly and hence driving the need for high-volume device testing, says the firm, for example for Internet over satellite connections, car ADAS systems, and other high-speed data transfer solutions with a projected volume of more than a billion units by 2020.

“Commercial test equipment does not test much about 50GHz,” says chief operating officer Cédric Mayor. “The current method used by most customers is in-house bench testing by hand, which is slow and expensive. This is because testing equipment above 50GHz becomes increasingly expensive as the frequency increases as it is non-standard,” he adds. “To solve this problem, we have created custom interfaces that step the test frequencies down into the range that commercial testers operate in. This enables us to provide a cost-effective testing service for ultra-high-frequency or mmW devices and builds on our existing services for high-frequency device testing.”

Another challenge of mmW devices is that the substrate used is often much more brittle than the usual CMOS, such as gallium arsenide (GaAs) or gallium nitride (GaN). The wafers are hence much more susceptible to breakage in transit and handling. To reduce the possibility of breakage, they are usually cut into quadrants once manufactured. A broken quadrant means fewer damaged parts compared to a whole broken wafer. However, the standard handling and test equipment is designed for circular wafers, so Presto has developed its own quadrant handling adapters for its test equipment.

It is also key to be able to maintain good correlation during the test and during the self-heating of the pulsed test methods, where continuous-wave measurement is normally used. In this case, all the fixturing must be able to control temperature and heat dissipation as well as include RF systematic error compensation for the measurements and maintain the correct reproducibility during production.

Among mmW applications already implemented or under consideration are short-range wireless backhaul, connecting small-cell wireless; data-center interconnect (DCI) for cloud servers; radar (primarily automotive); body scanners for airport security; chip-to-chip communications on printed circuit boards (where even short runs of wires or cables attenuate signals at these frequencies); and wireless communication protocols, such as 5G cellular, WiGig (802.11ad) and Wireless HD.

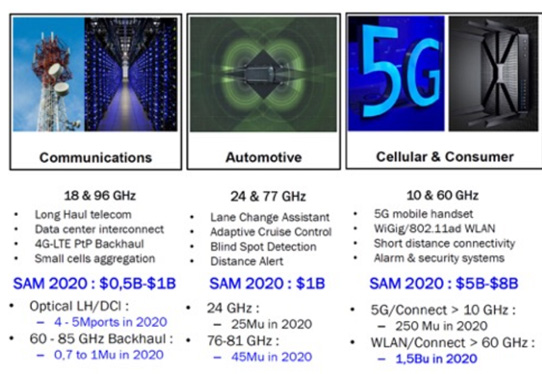

For convenience, the markets can be considered in three segments: communications, automotive and cellular/consumer, as shown in the table, which includes estimates of the potential served available market (SAM) and unit volumes. The first two of these are in now. Communications, driven by expansion in small-cell backhaul and cloud computing, has annual unit volumes for 2020 projected to be in the millions; and Automotive, driven by assisted driving (with autonomous driving on the horizon), has projected volumes in the tens of millions. The third vertical segment, Cellular & Consumer, driven by WiGig and 5G mobile, is in development now, with 2020 annual unit volumes projected to exceed 1 billion.

For further information, see the white paper ‘Enabling High Volume Test for Millimeter Wave RF Devices’ on Presto’s website.

Presto appoints COO and VP sales to address demand for IoT and related turnkey production & operations outsourcing