- News

21 March 2019

NIST boosts AlGaN/GaN nanowire UV LED electroluminescence fivefold at 365nm

The US National Institute of Standards and Technology (NIST) has made ultraviolet light-emitting diodes (LEDs) that, due to a special type of shell, produce five times higher light intensity than comparable LEDs based on a simpler shell design (M.D. Brubaker, K.L. Genter, A. Roshko, P.T. Blanchard, B.T. Spann, T.E. Harvey and K. A. Bertness, ‘UV LEDs Based on p-i-n Core-Shell AlGaN/GaN Nanowire Heterostructures Grown by N-polar Selective Area Epitaxy’, Nanotechnology, vol30 (2019) 234001).

Ultraviolet LEDs are used in a growing number of applications such as polymer curing, water purification and medical disinfection. Micro-LEDs are also of interest for visual displays. NIST is experimenting with nanowire-based LEDs for scanning-probe tips intended for electronics and biology applications.

The new, brighter LEDs are an outcome of NIST’s expertise in making high-quality gallium nitride (GaN) nanowires. Lately, researchers have been experimenting with nanowire cores made of silicon-doped GaN (which has extra electrons) surrounded by shells made of magnesium-doped GaN (which has a surplus of holes for missing electrons) to promote electron and hole recombination and hence the release of energy as light via electroluminescence.

The NIST group previously demonstrated GaN LEDs that produced light attributed to electrons injected into the shell layer to recombine with holes. The new LEDs have a small amount of aluminium added to the shell layer, which reduces losses from electron overflow and light reabsorption.

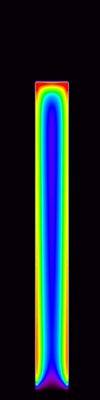

Picture: Model of nanowire-based LED showing that adding aluminium to the shell layer (black) directs all recombination of electrons and holes (spaces for electrons) into the nanowire core (multi-colored region), producing intense light. (Courtesy of NIST.)

Picture: Model of nanowire-based LED showing that adding aluminium to the shell layer (black) directs all recombination of electrons and holes (spaces for electrons) into the nanowire core (multi-colored region), producing intense light. (Courtesy of NIST.)

The brighter LEDs are fabricated from nanowires with a p-i-n structure, a tri-layer design that injects electrons and holes into the nanowire. The addition of aluminium to the shell helps to confine electrons to the nanowire core, boosting the electroluminescence fivefold (at an emission wavelength of 365nm).

“The role of the aluminum is to introduce an asymmetry in the electrical current that prevents electrons from flowing into the shell layer, which would reduce efficiency, and instead confines electrons and holes to the nanowire core,” says first author Matt Brubaker.

The nanowire test structures were about 440nm long with a shell thickness of about 40nm. The final LEDs, including the shells, were almost 10 times larger. Researchers found that the amount of aluminium incorporated into fabricated structures depends on nanowire diameter.

Group leader Kris Bertness says that at least two companies are developing micro-LEDs based on nanowires, and that NIST has a Cooperative Research and Development Agreement (CRADA) with one of them to develop dopant and structural characterization methods. The researchers have had preliminary discussions with scanning-probe companies about using NIST LEDs in their probe tips, and NIST plans to demonstrate prototype LED tools soon.

The NIST team holds US Patent 8,484,756 on an instrument that combines microwave scanning probe microscopy (SPM) with an LED for non-destructive, contactless testing of material quality for important semiconductor nanostructures such as transistor channels and individual grains in solar cells. The probe could also be used for biological research on protein unfolding and cell structure.

https://iopscience.iop.org/article/10.1088/1361-6528/ab07ed