- News

3 May 2019

Distributed feed-back gratings for indium gallium nitride laser diodes

Saudi Arabia’s King Abdullah University of Science and Technology (KAUST) claims the highest side-mode suppression ratio (SMSR) for indium gallium nitride (InGaN) distributed feed-back (DFB) laser diodes (LDs) so far [Jorge A. Holguín-Lerma et al, Appl. Phys. Express, vol12, p042007, 2019]. The highest SMSR achieved in the KAUST work was 36.9dB. The researchers comment: “This could enable immediate implementation of narrow-line green laser diodes on various applications, such as atom cooling, spectroscopy, and optical communications.”

Narrow-line emissions usually require external, complex and bulky filtering techniques to reduce the presence of side-modes relative to the main peak. An attractive alternative is monolithic integration of DFB gratings into the structure of the laser diode. Such an approach is already common in laser diodes constructed in other compound semiconductor systems serving wavelengths in the infrared and red parts of the electromagnetic spectrum. Also, DFBs have been applied to blue and ultraviolet InGaN devices, but with lower SMSR values.

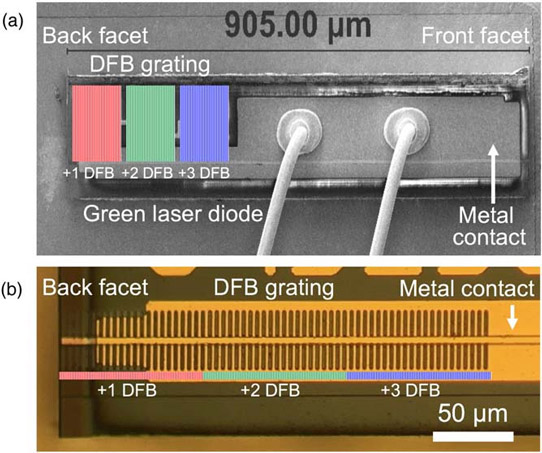

Figure 1: Device A: (a) scanning electron micrograph; (b) optical microscope image of back-facet section of laser diode with DFB grating. Red, green and blue periodic lines overlaid to represent DFB grating sections: +1 DFB, +2 DFB, and +3 DFB.

The KAUST researchers used an Osram PLP520 laser diode. The DFB grating was etched into the device surface using exposure to a focused ion-beam to create grooves. The grating period was 4.12μm, targeting an output wavelength of 515nm, assuming an effective refractive index in the laser diode material of 2.5. The green laser diode had a Fabry-Perot (FP) cavity length of ~905μm and the ridge width was ~4μm.

Two devices (A and B) were produced. The first, device A, used a DFB that was built up in three stages (DFB+1-+3) with the sections consisting of 22 groove/semiconductor pairs (Figure 1). As the DFB was lengthened, the SMSR increased. Under 300mA (8.28kA/cm2) continuous-wave current injection and the temperature maintained at 20°C, the SMSR was 0.2dB for the original device without DFB, while as the DFB was built up to the third +3 stage the SMSR increased successively in steps: 0.34dB, 1.45dB and 2.23dB (Figure 2).

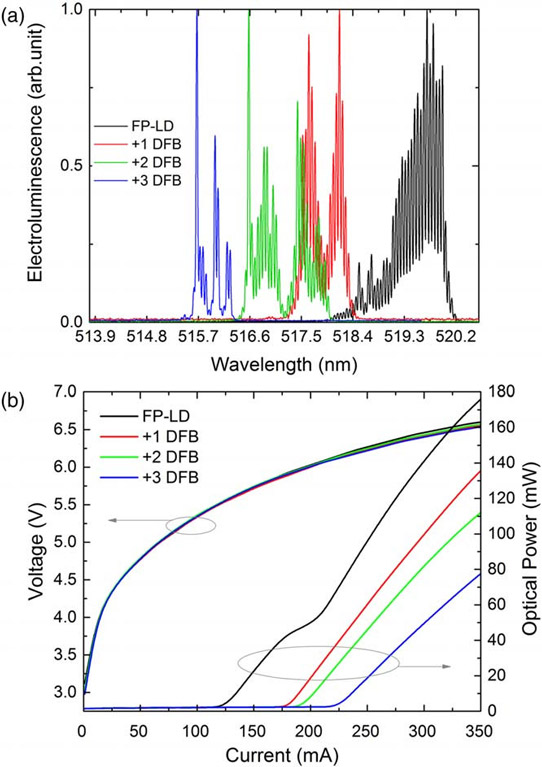

Figure 2: Electro-optical characteristics of device A: (a) spectral evolution after each consecutive DFB grating segment (i.e. +1 DFB, +2 DFB, +3 DFB); (b) light-output–current–voltage characteristics after each DFB grating segment.

The peak shifted to shorter wavelengths due to mismatch between the Bragg resonant wavelength and the main resonance of the Fabry-Perot cavity of the original laser diode. Another effect of the grating was to reduce the output power at 300mA: 141mW for the original laser diode and 49.6mW for the laser diode with +3 DFB. Mode selection and annihilation in the original laser diode did give a kink in the current-power curve, which was not seen in the DFB versions that are expected to have greater mode stability. The electrical voltage-current performance of the various device As was almost identical.

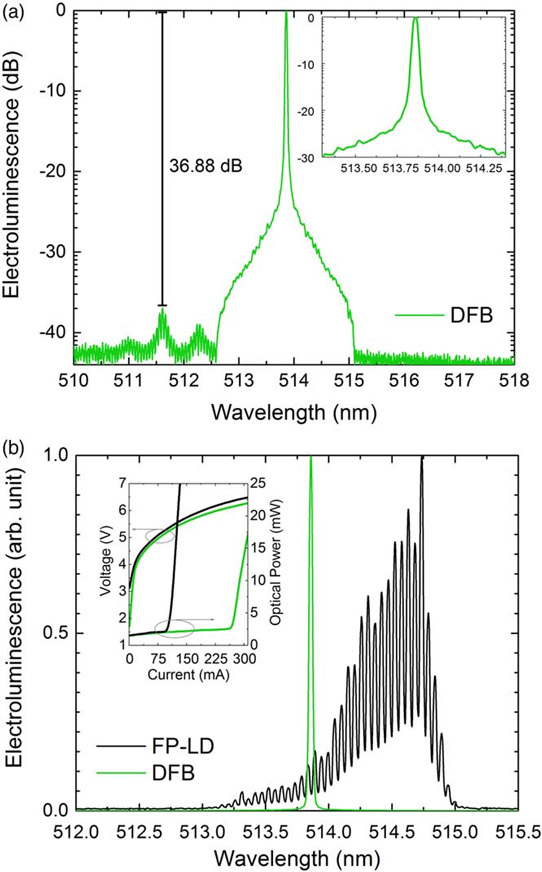

Using parameters derived from device A with +3 DFB sections, the researchers designed an improved 40-order DFB grating for device B. The new gating period was 4.114μm, giving narrow-line emission at 513.85nm. Under 300mA injection, device B achieved an SMSR of 36.9dB (Figure 3). The full-width at half-maximum (FWHM) linewidth of the laser diode without DFB was 544pm; adding the DFB to device B reduced this to 31pm. The corresponding optical powers were 149mW and 14mW. Again, the two set-ups had similar electronic behavior in terms of the current-voltage performance.

Figure 3: Electro-optical characteristics of DFB-LD (device B). (a) High-resolution optical spectra of green laser narrow-line emission (with detail inset). (b) Comparison of emission spectra before and after fabrication of DFB grating (DFB-LD). Inset: light-output–current–voltage characteristics.

Another factor was an increase in threshold current for the laser diode B with DFB: 263mA, compared with 102mA for the raw laser diode. The slope efficiency was also impacted: 0.54W/A without DFB and 0.32W/A with DFB. The external and maximum wall-plug efficiencies for device B with/without DFB were 20.7%/3.5% and 7.7%/1.3%, respectively.

The researchers think improvements could come from optimization of fabrication parameters such as ridge width and length, grating order and duty cycle, etching depth, and passivation.

InGaN DFB laser diodes InGaN Laser diodes

https://doi.org/10.7567/1882-0786/ab0a57

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.