- News

30 October 2019

Extremely thin gallium nitride wells enable deep ultraviolet lasing

Researchers in China have presented a deep ultraviolet (DUV) 249nm optically pumped III-nitride laser structure based on gallium nitride rather than the more usual wider-bandgap aluminium gallium nitride (AlGaN) quantum wells (QWs) [Maocheng Shan et al, ACS Photonics, published online 20 September 2019]. The very short wavelength of 249nm was enabled by the extreme confinement of very thin GaN wells in thin AlN barriers. The corresponding photon energy was 5.0eV, a couple of eV higher than the 3.3eV bandgap of bulk GaN.

The team, from Huazhong University of Science and Technology in China, King Abdullah University of Science and Technology (KAUST) in Saudi Arabia and Ningbo Institute of Materials Technology and Engineering in China, see potential applications for sub-280nm DUV lasers in sterilization, communication, optical storage, spectral analysis, and biochemical detection.

The researchers report that previously only spontaneous emission has been achieved in GaN/AlN multiple quantum well (MQW) systems, adding: “To date, there has not been any report of lasing which, if demonstrated, would truly demonstrate that the potentials of the AlN/GaN MQWs are on par with the AlGaN MQWs for high-performance DUV emitters.”

Among the problems for AlGaN DUV lasers are strong quantum-confined Stark effects (QCSEs) arising from electric fields, based in ionic charge polarization, that pull electrons away from holes, inhibiting recombination into photons. Also, high-Al-content AlGaN tends to emit radiation optically polarized in a transverse-magnetic mode, which is more difficult to use efficiently in light-emitting diode and edge-emitting laser structures.

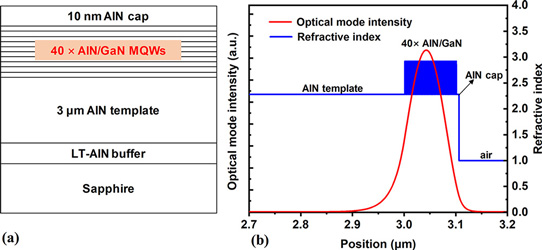

Metal-organic chemical vapor deposition (MOCVD) on 2-inch c-plane sapphire resulted in an AlN/GaN MQW laser structure. The 750°C low-temperature (LT) AlN buffer was 15nm thick. The 3μm AlN template layer was grown at 1230°C. X-ray rocking curve analysis suggested that the AlN template was of higher crystalline quality than previously used for AlGaN DUV laser structures.

A somewhat lower growth temperature of 1040°C was chosen for the MQW to ensure high-quality wells, avoiding evaporation of the more volatile GaN material. The GaN wells were designed to be 4 monolayers (MLs) thick, while the AlN barriers were 6MLs. In metric measurements, according to x-ray analysis, the wells and barriers were 1.0nm and 1.5nm thick, respectively.

The similarity of the quantum well (QW) and barrier (QB) thicknesses was expected to lead to a higher refractive index, compared with the usual situation with significantly thicker barriers. The researchers explain the use of 40 wells as being “due to comprehensive considerations of the lateral optical confinement, penetration depth of the excitation laser beam, gain medium volume, strain relaxation, and material and interface quality.”

Figure 1: (a) Schematic diagram of AlN/GaN MQW DUV laser grown on sapphire substrate; (b) simulated optical mode profile and refractive index distribution.

The final 10nm AlN cap was to provide surface passivation. The team says that ideally the top AlN layer would be thicker to provide a more symmetric waveguide effect coupled with the underlying AlN template. The reason for the thinness was to enable pumping from a 193nm argon fluoride (ArF) excimer laser with minimal absorption losses.

Optical simulations of the structure suggested a 35.4% confinement factor. The researchers explain: “The large factor was partially attributed to the use of high-index GaN QWs and large MQW pair number of 40. Also, it is partially caused by the comparable thicknesses between the GaN QWs and the AlN QBs, resulting in a larger average index.”

The material was prepared into 1mm-long cavity laser bars by thinning the sapphire substrate, and laser scribing and cleaving. No optical coating was applied to the facet.

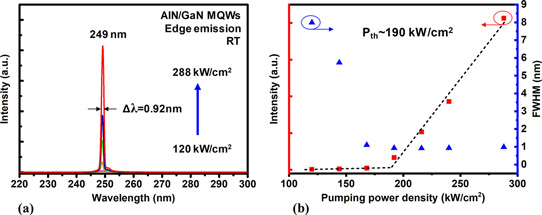

The laser pump was pulsed at 50Hz with 5ns duration. The emission peak was at 249nm with little shift between spontaneous and lasing operation (Figure 2). The researchers attribute this to a minimal QCSE, resulting from the thinness of the GaN QWs.

Figure 2: (a) Laser emission spectra and (b) peak intensity and line width of spectra as a function of pumping power density.

The team puts the lasing threshold at 190kW/cm2 pumping power density. The researchers report that this is comparable to AlGaN-based DUV laser structures on sapphire or AlN substrates. “Such a threshold can be mostly attributed to the high material and interface quality, large quantum and optical confinement, and smooth cleaved facet,” they write.

As the system passed through the laser threshold, the linewidth reduced from 8nm to 0.2nm full-width at half-maximum (FWHM). Above and below threshold the degree of optical polarization was 0.92 and 0.48, respectively. The polarization here was the ratio of the transverse electric intensity excess over the transverse magnetic to the total intensity (that is, (ITE-ITM)/(ITE+ITM)).

The researchers explain the favoring of TE polarization: “The TE dominance is caused by the topmost position of the heavy hole (HH) band of GaN and thereby the optical transition between the conduction band and the HH band.”

The even greater favoring of TE emission above laser threshold is attributed to a large TE-to-TM gain ratio in stimulated operation.

AlGaN DUV lasers DUV AlGaN GaN

http://dx.doi.org/10.1021/acsphotonics.9b00882

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.