- News

3 October 2019

Plessey’s micro-LED growth technology combines native blue and green epi on single wafer

UK-based Plessey, which develops embedded micro-LED technology for augmented-reality and mixed-reality (AR/MR) display applications, has extended the capability of its proprietary gallium nitride on silicon (GaN-on-Si) process to enable native blue and native green emission from the same wafer.

The potential of micro-LEDs is well known but several challenges remain before ramping up to large-scale consumer applications. To form RGB micro-LED displays, typical approaches are to use a pick & place process to transfer discrete R, G and B pixels or to use native-blue LEDs as the light source for subsequent colour conversion to red and green.

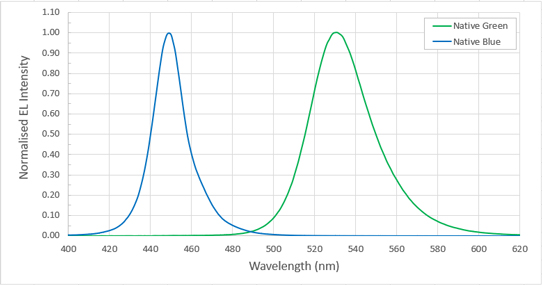

Plessey’s latest patented growth approach creates both native-blue and native-green emission layers on the same wafer. The monolithic formation of two colours significantly simplifies display manufacture. Green micro-LEDs have high efficiency with a narrow spectral width resulting in what is said to be an excellent colour gamut when operating alongside the high-performance blue micro-LEDs. The firm’s new approach forms micro-LEDs that exhibit high-current-density operation and long operational lifetime.

The monolithic integration of both the native-blue and green micro-LEDs on the same silicon substrate is the result of a concerted effort aimed at solving several challenges previously considered insurmountable. Among the issues preventing the integration of multiple wavelength diode junctions are, firstly, a magnesium memory effect and diffusion from the p-type cladding of the lower junction into the upper junction.

An additional process challenge to the integration of blue and green micro-LEDs is the precise tuning of the thermal budget during growth of the second junction to prevent indium phase separation in the blue active region. Plessey says it has precisely engineered the thermal budget to maintain high efficiency (IQE), low defectivity and high electrical conductivity required for high-brightness display applications.

A final operation in the formation of GaN micro-LEDs is a post-growth treatment aimed at removing hydrogen atoms that would otherwise compromise the conductivity of p-type layers. The presence of a second junction complicates the removal of hydrogen from the buried device structure, negating the effect of standard post-growth activation treatments.

Plessey says it has overcome all these challenges and created a monolithic blue and green micro-LED fabrication process that integrates these junctions vertically, separated by a sub-micron layer thickness, resulting in very reproducible and stable diode performance well beyond what is typical in the LED industry, it is reckoned.

“Our latest breakthrough has a multiplier effect on our previous successes with high-efficiency monolithic native blue arrays, native green arrays and hybrid bonding to backplane by demonstrating a way to synthesize the best of our know-how into a single die,” says Dr Wei Sin Tan, director of Epitaxy and Advanced Product Development. “This has enormous implications and will open the doors towards new innovations across a wide range of display applications. For mobile and large displays, a high-efficiency single RGB tile can now be used for mass-transfer and for micro-displays; this creates a path to the elusive single RGB panel ultra-high-resolution micro-LED AR display,” he adds. “This new process paves the way to commercial, high-performance micro-LED displays, bringing mass adoption of micro-LEDs in displays ever closer to reality.”

Micro-LED technology is continuing to emerge as the most likely successor to today’s smart high-performance display applications, making displays with smaller form factor even brighter and more power efficient than existing display technologies available, says Plessey.

Other recent milestones from Plessey includes the first wafer-level bonded monolithic 3000ppi (pixels per inch) GaN-on-Si micro-LED emissive display hybridized to an active-matrix CMOS backplane, and a high-efficiency native-green technology. Plessey says it is continuing to develop micro-LED display solutions with its roadmap including the production of full RGB micro-LED displays by 2020.

Plessey’s new native green LEDs boosts output for micro-LED displays