- News

2 September 2019

Mitsubishi Electric develops first multi-cell GaN-HEMT bonded directly to single-crystal diamond substrate

At the International Conference on Solid State Devices and Materials (SSDM) at Nagoya University, Japan (2-5 September), Japan’s Mitsubishi Electric Corp has announced that – in collaboration with the Research Center for Ubiquitous MEMS and Micro Engineering, National Institute of Advanced Industrial Science and Technology (AIST) – it has developed what is reckoned to be the first gallium nitride high-electron-mobility transistor (GaN HEMT) with a multi-cell structure (multiple transistors cells arranged in parallel) bonded directly to a single-crystal diamond heat-dissipating substrate.

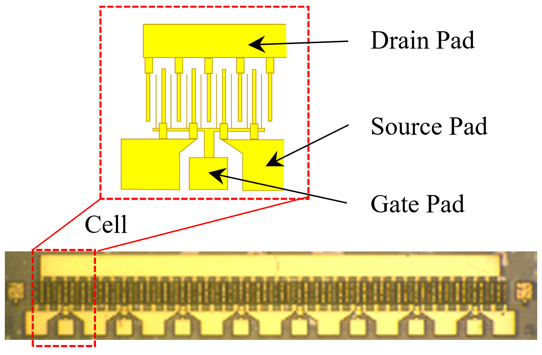

Picture: New GaN-on-diamond HEMT: view from above and cell structure.

Mitsubishi Electric handled the design, manufacture, evaluation and analysis of the GaN-on-diamond HEMT and AIST developed the direct bonding technology. Part of this achievement is based on results obtained from a project commissioned by Japan’s New Energy and Industrial Technology Development Organization (NEDO).

In recent years, high-power, high-efficiency GaN HEMTs have been adopted for high-power amplifiers in mobile communication base stations and satellite communications systems, helping to make such equipment smaller, lighter and more efficient. However, due to heat generation during high-power operation, the output performance inherent in GaN HEMTs cannot be realized and their reliability decreases.

Most existing GaN HEMTs that use a diamond substrate for heat dissipation are created using a GaN epitaxial layer foil from which silicon substrate has been removed and onto which diamond is deposited at high temperature. HEMTs are then fabricated on the diamond substrate of the flattened GaN wafer. However, because the thermal expansion coefficients of GaN and diamond are different, the wafer can warp greatly during the manufacturing process, making it difficult to fabricate large multi-cell GaN HEMTs.

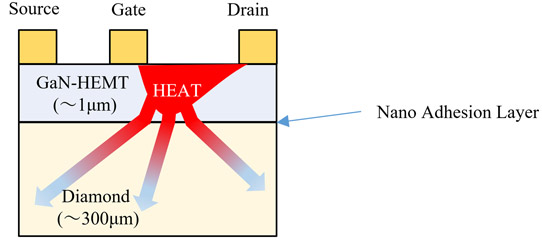

In the latest research a multi-cell GaN HEMT was fabricated then the silicon substrate was removed. The back surface of the GaN HEMT was then polished to make it thinner and flatter, after which it was bonded directly onto a diamond substrate using a nano adhesion layer. A multi-cell structure was used for the parallel alignment of eight transistor cells of a type found in actual products. Finally, a multi-cell GaN-on-diamond HEMT ─ the world’s first ─ was fabricated using a substrate with high heat dissipation made of single-crystal diamond.

Picture: Cross-sectional view of new GaN-on-diamond HEMT.

Using a single-crystal diamond (with high thermal conductivity of 1900W/mK) for superior heat dissipation suppresses temperature degradation, reducing the temperature rise in the GaN HEMT from 211.1°C to 35.7°C. This improves output per gate width from 2.8W/mm to 3.1W/mm as well as raising power efficiency from 55.6% to 65.2%, realizing significant energy conservation.

The new GaN-on-diamond HEMT should be able to improve the power-added efficiency (PAE) of high-power amplifiers in mobile communication base stations and satellite communications systems, helping to reduce power consumption. Mitsubishi Electric aims to refine the GaN-on-diamond HEMT prior to its commercial launch, targeted for 2025.

Mitsubishi Electric GaN HEMT Diamond