| Home | About Us | Contribute | Bookstore | Advertising | Subscribe for Free NOW! |

| News Archive | Features | Events | Recruitment | Directory |

News

13 April 2010

First demonstration of semipolar III–nitride ‘deep-UV’ LED

Researchers based in South Carolina have developed ‘first demonstration’ semipolar nitride semiconductor 307nm ultraviolet light-emitting diodes [Krishnan Balakrishnan et al, Jpn. J. Appl. Phys., vol49, p040206, 2010]. The 307nm wavelength is claimed as the shortest emission wavelength ever reported for a non c-plane III–nitride semiconductor-based LED. The researchers classify 307nm as ‘deep-UV’ (although some other groups define wavelengths shorter than 300nm as ‘deep-UV’).

By developing nitride semiconductor LEDs with reduced electric polarization fields, it is hoped that better recombination efficiencies will be achieved, boosting emission of UV light. In nitride semiconductors grown in the normal ‘c-direction’, electric fields of the order of several MV/cm can build up due to polarization effects. These fields tend to separate the negative (electron) and positive (hole) carriers, making it more difficult for them to recombine and emit photons.

The use of semipolar and non-polar nitride semiconductors is being actively developed for longer-wavelength LEDs, such as for green indium gallium nitride (InGaN) devices. It has been harder to develop such materials for UV wavelengths shorter than 350nm since the aluminum-based nitrides that are needed tend to form stacking faults and multiple structural phases when grown in non-standard directions.

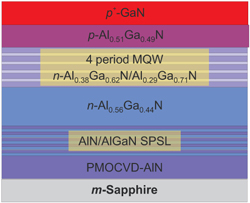

Figure 1: Schematic cross-section of the semipolar deep-UV LED structure.

Figure 1: Schematic cross-section of the semipolar deep-UV LED structure.

The latest research by University of South Carolina and Nitek Inc of Irmo, SC, USA uses m-plane sapphire substrates (Figure 1). A layer of aluminum nitride is then grown using pulsed metal-organic chemical vapor deposition (PMOCVD). A strain-relieving short-period super-lattice (SPSL) of alternating ultra-thin layers of AlN and AlGaN is used to enable crack-free metal-organic chemical vapor deposition (MOCVD) of subsequent layers.

The bottom contact consisted of n-AlGaN; the active, light-emitting region was a four-period multi-quantum well (MQW); the structure was topped off with a p-AlGaN electron-blocking layer (EBL) and a p+-GaN contact. EBLs are widely used in nitride LEDs to reduce over-spill of electrons into the p-type layers where they recombine non-radiatively or with parasitic wavelengths, reducing the efficiency for producing the desired short wavelength.

The researchers comment that they chose Al compositions in the MQW, n-contact, and SPSL that, like AlN and sapphire, were transparent to UV in the wavelength range 260–320nm. Various standard material characterizations were carried out: high-resolution x-ray diffraction, transmission electron microscopy, atomic force microscopy and scanning electron microscopy.

The x-ray diffraction measurements showed that the nitride layers grew in the (11-22) semipolar direction and that the SPSL was effective in improving the crystallinity of the material above – a typical rocking curve scan of a diffraction peak gave a full-width at half maximum (FWHM) value of 1386 arcsec for the AlN template, but for the n-AlGaN contact layer this was reduced to a sharper ~1110 arcsec.

Photoluminescence (PL) and electroluminescence (EL) studies were also carried out. The wavelength of the emission peak shifts very little (~0.5nm) with excitation power in PL measurements, unlike in comparison with c-direction devices where polarization effects led to a red-shift of ~1.9nm.

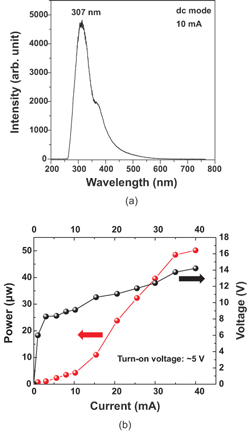

Conventional 100μm square LEDs were produced to carry out the EL work (Figure 2). A shoulder at 380nm is seen in the EL spectrum, which is believed to be due to recombination involving the magnesium acceptors used to create the p-type layers. The shoulder was absent in the PL spectra carried out on material without the p-type EBL or contact layers.

Conventional 100μm square LEDs were produced to carry out the EL work (Figure 2). A shoulder at 380nm is seen in the EL spectrum, which is believed to be due to recombination involving the magnesium acceptors used to create the p-type layers. The shoulder was absent in the PL spectra carried out on material without the p-type EBL or contact layers.

Figure 2: EL emission spectrum (a) and current-voltage-light output power (I–V–L) characteristics (b) of semipolar deep-UV LED.

The output power at 20mA DC input was 20μW, which the researchers find ‘reasonable for the first ever demonstration of a semipolar deep-UV LED’. Further work is being carried out to improve the device design and material quality in the hope of increasing optical output powers.

See related items:

Nichia achieves 2.78% external quantum efficiency for 281nm UV-LED

Dowa presents 320–350nm UV LED samples

Increased UV power from diamond LEDs enables E. coli sterilization

Multi-quantum blocking raises deep-UV LED efficiency

Improving deep UV emission on aluminum nitride templates

Deep ultraviolet power boost at shorter wavelengths

![]() Search: Deep UV LEDs AlGaN AlN Sapphire substrates

Search: Deep UV LEDs AlGaN AlN Sapphire substrates

Visit: http://jjap.ipap.jp/link?JJAP/49/040206

Visit: www.ee.sc.edu/research/microlab/Default.htm

Visit: www.nitekusa.com

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.