News: Suppliers

17 April 2020

LayTec’s EpiCurve TT used in AlInN composition control for III-nitride VCSELs

In-situ metrology system maker LayTec AG of Berlin, Germany notes that high-effiicency and high-power operation have been recently demonstrated for blue gallium nitride (GaN)-based vertical-cavity surface-emitting lasers (VCSELs) with AlInN/GaN distributed Bragg reflectors (DBRs) [Kuramoto et al, Appl. Sci. 2019, 9, 416; doi:10.3390/app9030416].

These AlInN/GaN DBRs are used at the front (emitting) side of the VCSEL that emits through the GaN substrate and is completed by a second, dielectric DBR at the VCSEL’s back-side. Hence, perfect lattice match of the AlInN in the front DBR is essential for enabling extremely low-defect InGaN layers in the active zone of the device that is grown on top of the AlInN/GaN DBRs.

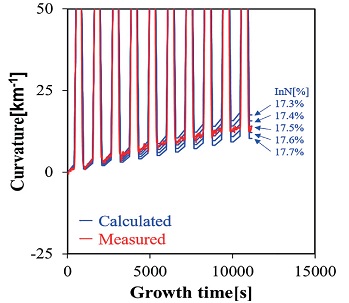

Figure 1: Measured in-situ wafer bow of GaN/AlInN DBRs on GaN substrate as measured (red line) and simulated for several InN mole fractions (blue lines). Shown is a magnified view to the low-temperature (825°C) AlInN wafer curvature sequence.

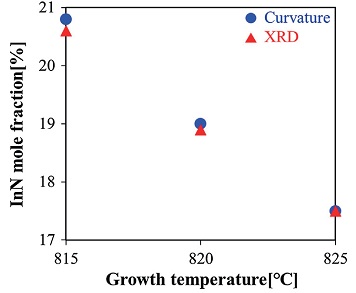

Figure2: InN mole fraction values estimated from the in-situ curvature measurements and the ex-situ XRD measurements.

A recent paper by Meijo University (Hiraiwa et al., Journal of Crystal Growth 531 (2020) 125357) demonstrated that LayTec’s EpiCurve TT metrology tool is powerful for revealing and controling the AlInN strain and alloy compositions at the accuracy levels of x-ray diffraction (XRD) already during growth of the epitaxial layers.