News: Suppliers

25 February 2020

k-Space issues application note ‘Continuous Reflectivity Measurements for Growth Rate and Emissivity-Corrected Pyrometry in MBE Systems’

k-Space Associates Inc of Dexter, MI, USA – which makes in-situ, ex-situ and in-line thin-film metrology instrumentation for both research and manufacturing of microelectronic, optoelectronic and photovoltaic devices – has released a new technical note on continuous reflectivity measurements for growth rate and emissivity-corrected pyrometry (ECP) in molecular beam epitaxy (MBE) systems. Real-time growth rate and wafer temperature measurement during MBE growth are important to the final product quality and yield, notes the firm.

These measurements have been historically difficult to obtain, says k-Space. Taking the measurement is challenging because of variation in the reflectivity signals caused by substrate wobble. These variations are exacerbated by the relatively long substrate-to-detector distances in MBE systems (typically greater than 24”) compared with metal-organic chemical vapor deposition (MOCVD) systems (typically less than 12”). This results in oscillations in both the measured reflectivity and the temperature.

The kSA Integrated Control for Epitaxy (kSA ICE) instrument provides reflectivity and ECP measurements that can be utilized during MBE growth. This results in real-time material deposition calibration and process control in both continuous and triggered modes. The optics have been configured to overcome the wobble and path length issues in MBE.

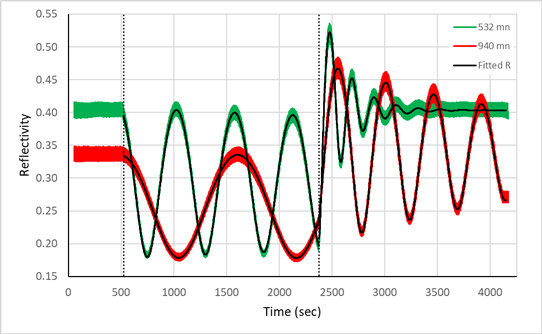

Graphic: 532nm- and 940nm-wavelength reflectivity during growth of 250nm of AlAs followed by 500nm of GaAs on a GaAs substrate, and the corresponding virtual interface reflectivity fits for each layer and wavelength. (from ‘Continuous Reflectivity Measurements for Growth Rate and Emissivity-Corrected Pyrometry in MBE Systems’).

The Figure shows the simultaneous measurement of the surface reflectivity at 532nm and 940nm during the growth of aluminium arsenide (AlAs) and gallium arsenide (GaAs) films on a GaAs substrate. For a deposition with constant growth rate, the oscillation period is proportional to λ/2n. As such, the oscillation period of the 532nm reflectivity data is shorter than that of the 940nm reflectivity data, as seen in the Figure. A shorter oscillation period allows the fit to converge earlier in the growth. As a result, the shorter-wavelength 532nm-wavelength reflectivity data allows the calculation of film thickness earlier in the growth and allows characteristically thinner layers to be measured (under 350nm thick). Conversely, 940nm-wavelength reflectivity continues to produce strong oscillations beyond 350nm.

Additional data is available in the full technical paper ‘Continuous Reflectivity Measurements for Growth Rate and ECP in MBE Systems’.