News: LEDs

21 July 2020

ALLOS and KAUST co-developing high-efficiency nitride-based red LEDs on silicon

IP licensing & technology engineering firm ALLOS Semiconductors GmbH of Dresden, Germany is collaborating with professor Ohkawa and his team at Saudi Arabia’s King Abdullah University of Science and Technology (KAUST) to realize high-efficiency nitride-based red LEDs on large-diameter silicon substrates.

The teams are addressing fundamental issues such as the large lattice mismatch and the quantum-confined Stark effect (QCSE), which are preventing the adoption of red nitride-based LEDs for practical industry usage. In particular, to reduce manufacturing complexity and cost for the emerging field of micro-LED displays there is strong demand to enable the growth of red LEDs on large-diameter wafers in addition to the established blue and green color LEDs in the nitride system.

In this context, by using local strain compensation and a modified metal-organic chemical vapor deposition (MOCVD) reactor design, Ohkawa and team have developed an indium gallium nitride (InGaN)-based red LED stack with low forward voltage of less than 2.5V and high efficiency.

The researchers have already grown red LEDs on sapphire substrates and gallium oxide (Ga2O3) substrates (‘633-nm InGaN-based red LEDs grown on thick GaN underlying layers with reducing in-plane residual stress’, D Iida et al, Applied Physics Letters 116, 162101 (2020); ‘Demonstration of low forward voltage InGaN-based red LEDs on β-Ga2O3 substrates’, D Iida et al, Applied Physics Express 13, 031001 (2020)).

For potentially higher-performance red LEDs by using strain engineering at the wafer level - in particular for large-wafer diameters - the team is now extending its work to silicon substrates by collaborating with ALLOS. This also enables huge advantages for mass production due to the scalability up to 300mm diameter and thus processability in silicon process lines. For micro-LED displays - in particular monolithically integrated micro-displays for augmented reality (AR) application, for example - this is another important enabler, says ALLOS.

The firm says that the unique high crystal quality of gallium nitride on silicon (GaN-on-Si) technology with a threading dislocation density (TDD) of ~2x108cm-2 is the pre-condition to achieve at least the same performance red LED as on sapphire. Furthermore, ALLOS’ precise strain-engineering - which enables excellent emission uniformity for blue and green LED as well as flat wafer bow for 200mm and 300mm diameters - is used to optimize the growth conditions for red LED.

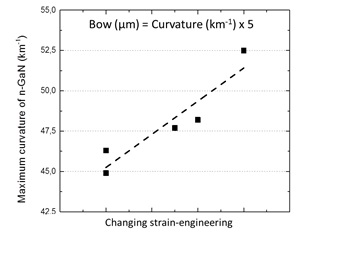

Figure 1: ALLOS’ in-line process control enables +/-5µm bow range.

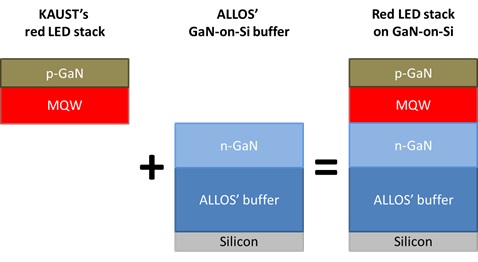

Both teams combine their unique technologies to handle strain and optimize crystal growth conditions for GaN-on-Si and red LEDs. To this end, the KAUST team will grow its red LED stack on top of ALLOS’ GaN-on-Si-buffer layers, which will be fine-tuned during the collaboration to optimize the performance of KAUST’s red LED stack:

Figure 2: In the collaboration, ALLOS’ established methods of integrating different LED stacks with its high crystal quality and strain-engineering buffer technology are used.

“From personal experience I am aware how challenging it is to realize high-efficiency red LED,” says ALLOS’ co-founder & chief technology officer Dr Atsushi Nishikawa. “From ALLOS’ side we can provide our established blue and green high-quality GaN-on-Si micro-LED epiwafers of up to 300mm diameter. Furthermore, we see the opportunity that our unique strengths in strain engineering can contribute to improved red LED performance,” he adds.

“Our team has developed a high-efficiency red LED stack and continues to push the boundaries in this very challenging field,” says Ohkawa. “When talking to ALLOS, we of course were interested in the scalability up to 300mm - but the capability to control the strain engineering so precisely and in such a large process windows promises more progress for red LED performance.”