News: Optoelectronics

19 March 2020

Indium tin oxide as cladding for more efficient green laser diodes

Researchers based in China have used indium tin oxide (ITO) as an upper cladding component in green laser diodes (LDs) rather than the more usual aluminium gallium nitride (AlGaN), reducing thresholds to as low as 1.6kA/cm2 [Lei Hu et al, Photonics Research, vol8, p279, 2020]. A conventional AlGaN-clad laser diode with the same structure otherwise achieved a threshold of 5kA/cm2.

The team from Suzhou Institute of Nano-Tech and Nano-Bionics and University of Science and Technology of China hope to use their work to fill the ‘green gap’ for efficient laser diodes between the near-infrared to red range, and the blue to near-ultraviolet. The central range of the gap is 500-550nm wavelength range. At the same time, these wavelengths are in the center of the visible spectrum, 380-794nm, and hence are key in red-green-blue display applications.

The low refractive index of ITO (about 2) should enable better confinement of the light generated in the laser cavity, compared with higher-index AlGaN. Also, ITO deposition is a relatively low-temperature process (around 300°C), which reduces thermal damage to the indium gallium nitride (InGaN) multiple quantum wells (MQWs) that generate the green light.

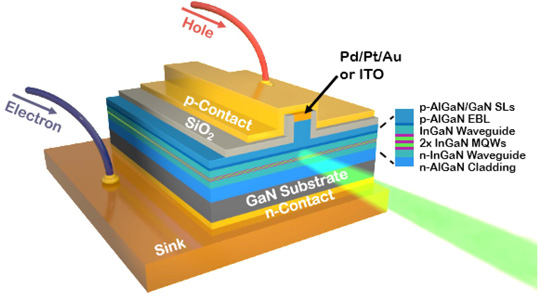

The researchers designed three laser diode structures with varying p-Al0.08Ga0.92N cladding thickness, which were grown by metal-organic chemical vapor deposition (MOCVD) on c-plane GaN substrates (Figure 1). The cladding thicknesses were 150nm, 300nm and 500nm. The cladding was actually deposited as a 2.5nm/2.5nm p-AlGaN/p-GaN superlattice (SL) with 8% average Al content, with the aim of reducing series resistance.

Figure 1: Hybrid laser diode with ITO cladding layer or conventional laser diode with Pd/Pt/Au electrode.

The n-side cladding was designed to consist of Al0.07Ga0.93N. The InGaN waveguide layers had 4% indium content on the n-side and were unintentionally doped on the p-side. The electron-blocking layer (EBL) contained 15% Al.

The material was processed into ridge-waveguide laser diodes with inductively coupled plasma (ICP) etch, 200nm silicon dioxide ICP CVD, and 200nm ITO evaporation at 300°C. The p-electrode metal was titanium/gold, while the n-contact was through titanium/aluminium/titanium/gold deposited on the back of the wafer. A conventional laser diode without ITO was fabricated on a 500nm p-AlGaN cladding sample, where the p-electrode consisted of palladium/platinum/gold (Pd/Pt/Au). The laser diode cavities were formed by cleaving the fabricated devices and coating the facets with dielectric layers.

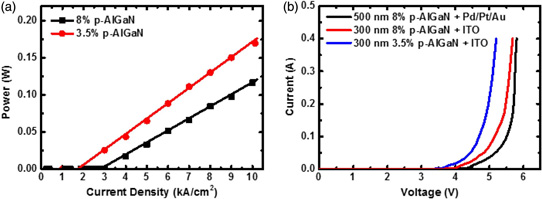

The devices were subjected to 0.4μs current pulses at a rate of 10kHz with a view to eliminating self-heating effects. The threshold of the conventional laser diode without ITO came in at 5kA/cm2 current density. The slope efficiency of the light output power was 0.16W/A.

The ITO device with the thinnest AlGaN cladding of 150nm reduced the threshold to 2.5kA/cm2. The sloped efficiency increased to 0.20W/A. The intermediate cladding laser diodes also showed reduced thresholds to a lesser extent. The 300nm-clad laser diode also showed increased slope efficiency of 0.19W/A.

The light output wavelengths were just above 500nm: 506nm, 512nm and 508nm, for the ITO laser diodes with 500nm, 300nm and 150nm p-AlGaN cladding, respectively. The conventional device wavelength was 505nm. The researchers attribute the wavelength variation to different MOCVD growth temperatures. These values are toward the blue end of the 495nm-570nm green range.

Studying the subthreshold light emission suggested increased non-radiative recombination in the samples with thicker p-AlGaN cladding. The researchers comment; “We believe that the increasing non-radiative recombination centers result from the increasing thermal budget due to increasing growth time of the p-AlGaN cladding layer.”

AlGaN is generally grown at raised temperature that tends to degrade the InGaN in the light-emitting MQWs and the waveguide layers. The team points particularly to the extended growth time at high temperature as damaging to the QW structure.

Simulations suggest that the lower light absorption of the ITO cladding material is not a particularly significant factor in reducing the threshold, except in so far as it enables a thinner p-AlGaN cladding layer.

The team also carried out simulations that suggested that reducing the Al content in the p-AlGaN cladding to 3.5% could improve hole concentration and injection efficiency, further reducing thresholds. A laser diode was fabricated with 300nm 3.5% Al-content p-cladding, and the threshold was reduced to 1.6kA/cm2. This compared with 2.9kA/cm2 for the 300nm 8%-Al cladding laser diodes. Also, the slope efficiency increased slightly from 0.19W/A to 0.20W/A.

Figure 2: (a) Light output power versus current density curves for ITO laser diodes with 300nm p-AlGaN cladding layers with 8% and 3.5% Al-content. (b) Current density versus voltage for three different laser diodes.

The 3.5%-Al cladding laser diode also showed reduced operating voltage of 0.6V lower than the conventional laser diode with 4kA/cm2 injection current density. This indicated reduced series resistance from the thinner AlGaN.

The researchers used the improved performance to construct a laser diode with 400mW light output power. The high performance was enabled by a 15μm-wide, 1200μm-long ridge with the front facet reflectivity reduced to 40%. The threshold current density was 3.9kA/cm2. The slope efficiency was 0.44W/A, and the current injection at 400mW output was 9kA/cm2.

ITO ITO cladding Green laser diodes AlGaN

https://doi.org/10.1364/PRJ.381262

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.