News: Suppliers

20 May 2020

LayTec’s EpiTT Band Edge tool used for ZnO substrate temperature and growth rate control in MBE

In a recent project, the group of professor C. Meier at the University of Paderborn – which is focusing on modern methods of nanofabrication and nanotechnology with the aim of developing novel devices for photonics, plasmonics and nonlinear processes – has grown zinc oxide (ZnO) structures using molecular beam epitaxy (MBE) both by homoepitaxy on ZnO substrates and by heteroepitaxy on sapphire and silicon substrates.

In-situ metrology system maker LayTec AG of Berlin, Germany is supporting this research with a newly developed version of its EpiTT Band Edge tool that combines long-wavelength (1550nm) pyrometry with short-wavelength ZnO band-edge temperature sensing as well as with 405nm in-situ reflectance.

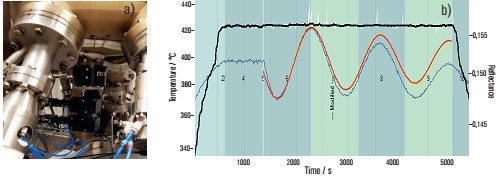

Picture: EpiTT Band Edge for oxide semiconductor MBE: (a) the optical head, as mounted on a Riber C12 MBE system, and (b) example in-situ data – ZnO substrate temperature (black line) and 405nm reflectance (blue line). After surface roughening effects have been numerically removed (yellow line), the best fit (red line) yields a growth rate of 0.078nm/s.

While temperature sensing on silicon substrates and growth rate measurements during growth of ZnMnO/ZnO heterostructures are covered by the EpiTT’s standard performance, the Figure shows the performance of the EpiTT Band Edge even during ZnO/ZnO homoepitaxy: the temperature of the ZnO substrate is measured throughout the process by the integrated Band Edge temperature module, and 405nm reflectance gives access to the homo-epitaxial growth rate. At this wavelength, located close to the ZnO band-edge, the tiny (±0.5%) Fabry–Perot oscillations of ZnO grown on ZnO (with different doping levels) can be resolved, notes LayTec.