News: LEDs

15 December 2021

MICLEDI produces micro-LED arrays for AR glasses on 300mm CMOS wafers

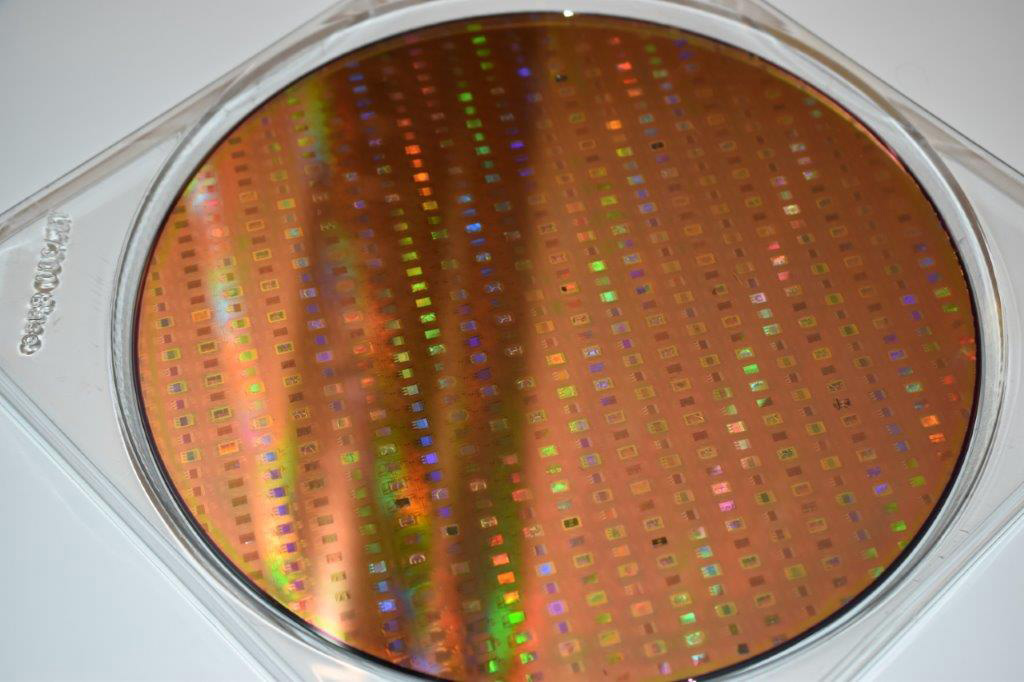

MICLEDI Microdisplays B.V. of Leuven, Belgium, a fabless developer of micro-LED displays for high-end augmented reality (AR) glasses, has demonstrated what it claims are the first micro-LED arrays-for-AR built on a 300mm CMOS manufacturing platform. The manufacturing precision, performance and cost-efficiency offered by the 300mm product strategy targets displays for AR glasses manufacturers.

Picture: MICLEDI microLED arrays processed on 300mm wafers (via reconstitution and W2W bonding).

MICLEDI’s solution is positioned to address the needs of future AR glasses in terms of display size, resolution, brightness, image quality, power consumption and cost. The firm says that the uniqueness of the technology rests on the following attributes:

- CMOS-fab-compatible RGB epitaxial materials reconstituted on 300mm CMOS wafers, co-integrated with advanced-node CMOS backplane ASICs via W2W (wafer-to-wafer) hybrid bonding;

- pixel-level Fresnel lens beam shaping for high-efficiency waveguide integration;

- micro-LED technology tailored for industry-standard tooling and process steps available for volume manufacturing at CMOS foundries.

As a spin-off of nanoelectronics research center Imec, MICLEDI has leveraged IMEC’s extensive background in 3D integration technologies and unique access to its 300mm CMOS pilot-line infrastructure for micro-LED development and prototyping.

The next generation of AR glasses

AR headsets are currently heavy and bulky, image realism is poor, resolution is low, and headsets are costly. Nearly every leading technology company is investing in AR to drive the future of their consumer offerings, and micro-LED displays are a mission-critical component. According to industry analyst firm Yole Developpement, demand for micro-displays in AR headsets is projected to grow at a compound annual growth rate (CAGR) of >100%, rising to more than $1.8bn in 2025 and more than $4.9bn in 2027.

“AR headsets today can be found in industrial and medical niche markets. We intend to change that by enabling AR glasses that are stylish, compact, lightweight, with long battery life, and images that look just like reality,” says CEO Sean Lord. “Our 300mm manufacturing flow is the technology needed to overcome the challenges with first- and second-generation AR glasses and is necessary to achieve the features consumers will require for the ultimate visually immersive AR experience.”

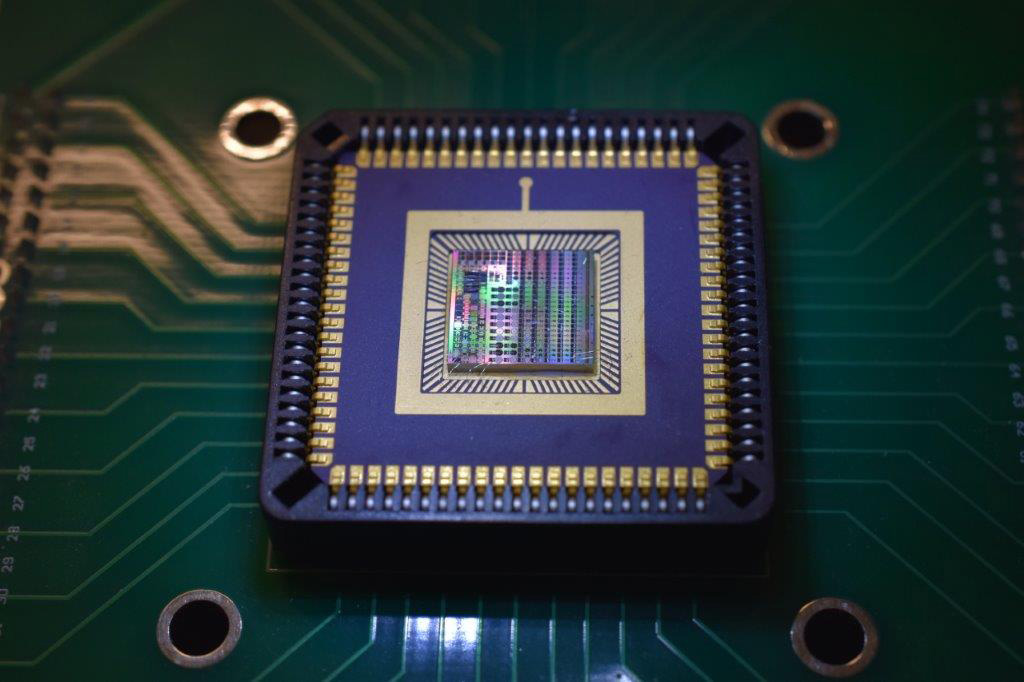

Picture: MICLEDI’s packaged micro-LED dies with test arrays.

First demonstration units at CES 2022

The 2022 Consumer Electronics Show (CES) in Las Vegas in January marks the first availability of MICLEDI’s demonstration units. “CES is where advanced technologies take center stage for all the world to see and AR is one area that is in rapid adoption with leaders from FAANG companies [Facebook, Amazon, Apple, Netflix and Google] and a plethora of smaller innovators,” says Lord.

At CES, MICLEDI is located at booth 19099 in Central Hall. The firm also has a suite at The Venetian for private meetings.

MICLEDI plans to sample its micro-LEDs to customers beginning in first-quarter 2022.