News: Markets

12 October 2021

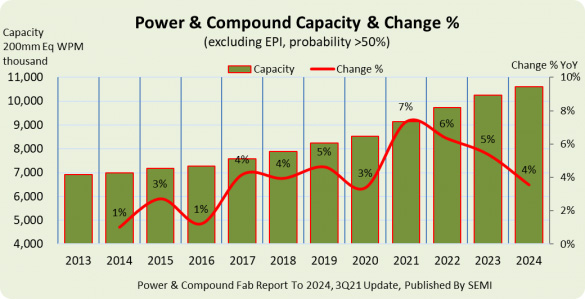

Power and compound fab capacity to top record 10 million wafers per month in 2023

Fueled by pent-up demand for automotive electronics caused by semiconductor supply chain disruptions wrought by the COVID-19 pandemic, worldwide installed capacity for power and compound semiconductor fabs is projected to top 10 million wafers per month (WPM) for the first time in 2023, growing to 10.24 million WPM (in 200mm equivalents), then climbing to 10.6 million WPM in 2024, forecasts industry association SEMI in its ‘Power & Compound Fab Report to 2024’.

China is expected to claim the largest share of installed capacity (33%) by 2023, followed by Japan at 17%, Europe and the Mideast (EMEA) at 16%, and Taiwan at 11%. These proportions are expected to change little as the industry remains on track to add more than 360,000WPM in 2024.

The report notes that 63 companies are expected to add more than 2 million WPM (in 200mm equivalents) from 2021 through 2024. Infineon, Hua Hong Semiconductor, STMicroelectronics and Silan Microelectronics will lead the way, together adding a projected 700,000WPM.

Installed capacity for the power and compound fab industry grew 5% year-over-year (YOY) in 2019 and 3% in 2020 before surging 7% in 2021. Year-on-year growth is projected to remain strong at 6% in 2022 and 5% in 2023 as the industry tops the 10 million WPM mark.

The industry is also adding production facilities. From 2021 through 2024, 47 high-probability facilities and lines (R&D to high volume, including epitaxial wafers) are expected to go online to bring the industry total to 755, a number that could be eclipsed if new facilities and lines are announced.

The SEMI ‘Power & Compound Fab Report to 2024’ covers 957 facilities and lines operational over the 12 years from 2013 to 2024, including facilities that are or will be closed, and new facilities starting operation.