News: Microelectronics

12 December 2022

ST boosts EV performance and driving range with new silicon carbide power modules

STMicroelectronics of Geneva, Switzerland has released new high-power silicon carbide (SiC) modules for electric vehicles (EVs) that boost performance and driving range. In production now, the ACEPACK DRIVE modules have been selected for Hyundai’s E-GMP electric vehicle platform (which is shared by the Kia EV6 and several models).

Five new SiC MOSFET-based power modules provide flexible choices for vehicle makers, covering a selection of power ratings and support for operating voltages commonly used in EV traction applications. Housed in ST’s ACEPACK DRIVE package optimized for traction applications, the power modules are said to be reliable (due to sintering technology), robust, and easy for manufacturers to integrate into EV drives. Internally, the main power semiconductors are ST’s third-generation (Gen3) STPOWER SiC MOSFETs, which combine what are claimed to be industry-leading figure of merit (RDS(ON) x die area) with very low switching energy and super performance in synchronous rectification.

“ST silicon carbide solutions are enabling major automotive OEMs to set the pace of electrification when developing future generations of EVs,” says Marco Monti, president of ST’s Automotive and Discrete Group. “Our third-generation SiC technology ensures the greatest power density and energy efficiency, resulting in superior vehicle performance, range and charge time.”

Hyundai Motor Company has chosen ST’s ACEPACK DRIVE SiC-MOSFET Gen3-based power modules for its current-generation EV platform, called E-GMP. In particular, the modules will power the Kia EV6. “ST’s SiC MOSFET-based power modules are the right choice for our traction inverters, enabling longer range,” says Sang-Cheol Shin, Inverter Engineering Design Team at Hyundai Motor Group. “The cooperation between our two companies has realized a significant step towards more sustainable electric vehicles, leveraging ST’s continuous technological investment to be the leading semiconductor actor in the electrification revolution.”

ST has already supplied STPOWER SiC devices for more than three million mass-produced passenger cars worldwide. With the recently announced fully integrated SiC substrate manufacturing facility in Catania, expected to start production in 2023, ST is moving quickly to support the rapid market transition towards e-mobility.

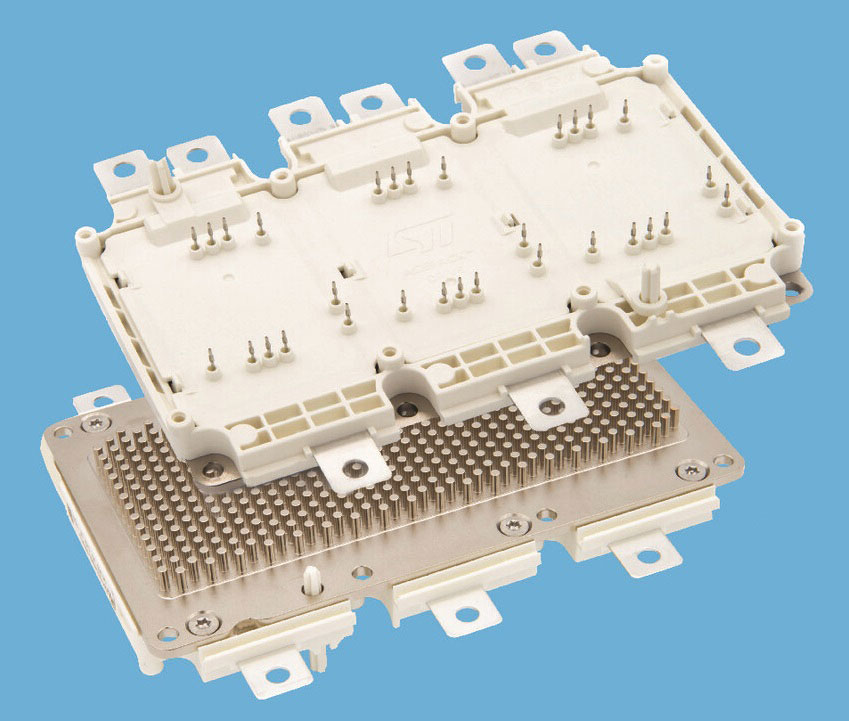

ST’s 1200V ADP280120W3, ADP360120W3 and ADP480120W3(-L) modules are already in full production. The 750V ACEPACK DRIVE ADP46075W3 and ADP61075W3 will be in full production by March 2023. They enable a plug-and-play solution for traction inverters, compatible with direct liquid cooling, and featuring a pin-fin array for efficient heat dissipation. Specified up to a maximum junction temperature of 175°C, they provide long-lasting and reliable press-fit connections and dice sintered to substrate to ensure extended lifetime in automotive applications. ST will extend the product portfolio to include insulated-gate bipolar transistor (IGBT)- and diode-based ACEPACK DRIVE versions.

The modules feature active metal brazed (AMB) substrate technology, known for excellent thermal efficiency and mechanical strength, mounting a dedicated NTC (negative temperature coefficient thermistor) for each substrate. They are also available with a choice of welded or screw-fit busbar, giving flexibility to address different mounting requirements. A long-busbar option further extends the flexibility by allowing the choice of a Hall sensor to monitor the motor current.

ST to build €730m silicon carbide wafer factory in Catania, Italy

ST cooperating with Semikron to integrate SiC power technology in EV drives

ST launches third generation of STPOWER SiC MOSFETs