News: Optoelectronics

29 June 2022

Intel Labs demos eight-wavelength laser array on silicon wafer with matched power and uniform spacing

Intel Labs of Santa Clara, CA, USA has announced advances in multi-wavelength integrated optics, including the demonstration of an eight-wavelength distributed feedback (DFB) laser array that is fully integrated on a silicon wafer and delivers output power uniformity of ±0.25dB and wavelength spacing uniformity of ±6.5% that exceed industry specifications.

“This new research demonstrates that it’s possible to achieve well-matched output power with uniform and densely spaced wavelengths,” says senior principal engineer Haisheng Rong. “Most importantly, this can be done using existing manufacturing and process controls in Intel’s fabs, thereby ensuring a clear path to volume production of the next-generation co-packaged optics and optical compute interconnect at scale.”

It is reckoned that the advance will enable the production of the optical source with the required performance for future high-volume applications, such as co-packaged optics and optical compute interconnect for emerging network-intensive workloads including artificial intelligence (AI) and machine learning (ML). The laser array is built on Intel’s 300mm silicon photonics manufacturing process to pave the way for high-volume manufacturing and broad deployment.

Picture: Eight-channel hybrid III-V/silicon DFB laser array (courtesy of Intel Corp).

Market research firm Gartner forecasts that silicon photonics will be used in more than 20% of all high-bandwidth data-center communications channels by 2025 (up from less than 5% in 2020) and will represent a total available market of $2.6bn. The growing demand for low power consumption, high bandwidth and faster data transfer is driving the need for silicon photonics to support data-center applications and beyond.

Why it matters

Optical connections began replacing copper wires in the 1980s due to the inherent high bandwidth of light transmission in optical fibers instead of electrical impulses transmitted through metal wires. Since then, the technology has become more efficient due to reduced component size and cost, leading to breakthroughs in the past few years in using optical interconnects for network solutions, typically in switches, data centers and other high-performance computing (HPC) environments.

With the rise of electrical interconnect performance limitations, integrating silicon circuitry and optics side by side on the same package holds the promise of a future input/output (I/O) interface with improved energy efficiency and longer reach. These photonic technologies were achieved in Intel’s fab using existing process technologies, which translates to favorable cost reductions of large-scale manufacturing.

Recent co-packaged optics solutions using dense wavelength division multiplexing (DWDM) technology have shown the promise of increasing bandwidth while significantly reducing the physical size of photonic chips. However, it has been very difficult to produce DWDM light sources with uniform wavelength spacing and power until now.

Intel says that this new advance ensures consistent wavelength separation of light sources while maintaining uniform output power, resulting in meeting one of the requirements for optical compute interconnect and DWDM communication. The next generation of compute I/O using optical interconnect can be tailor-made for the extreme demands of future high-bandwidth AI and ML workloads.

How it works

The eight-wavelength DFB array was designed and fabricated using Intel’s commercial 300mm hybrid silicon photonics platform, which is used to manufacture production optical transceivers in volume. This innovation is reckoned to represent a significant advance in the capabilities of laser manufacturing in a high-volume complementary metal-oxide-semiconductor (CMOS) fab by utilizing the same lithography technology used to manufacture 300mm silicon wafers with tight process control.

For this research, Intel used advanced lithography to define the waveguide gratings in silicon prior to the III-V wafer bonding process. This technique resulted in better wavelength uniformity compared with conventional lasers manufactured in 3-inch or 4-inch III-V wafer fabs. In addition, due to the tight integration of the lasers, the array also maintains its channel spacing when the ambient temperature is changed.

What’s next

Intel says that, as a pioneer of silicon photonics technology, it is committed to developing solutions to meet the growing demand for a more efficient and resourceful network infrastructure. Core technology building blocks under development include light generation, amplification, detection, modulation, CMOS interface circuits and package integration technologies.

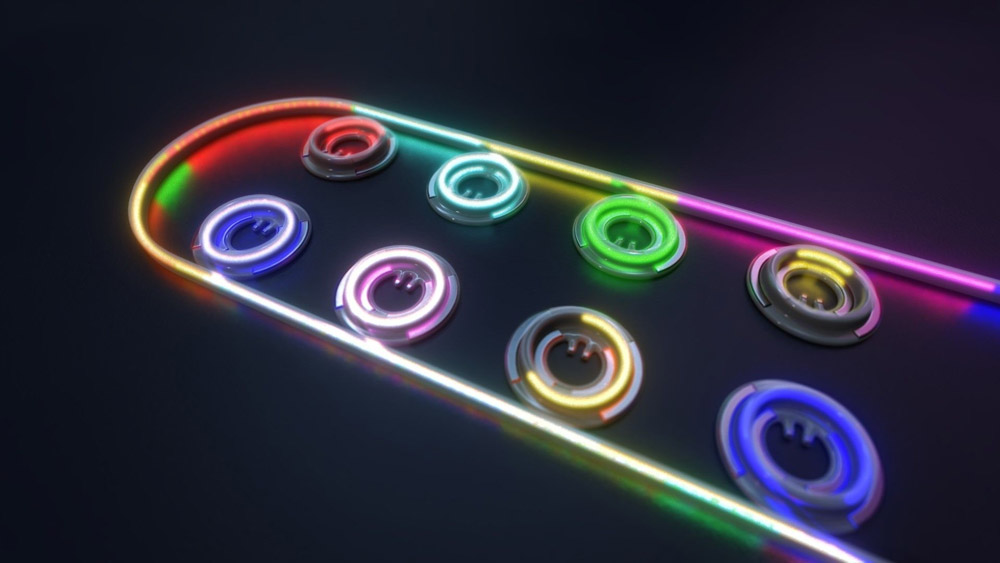

Picture: Eight micro-ring modulators and optical waveguide. Each micro-ring modulator is tuned to a specific wavelength, do each micro-ring can individually modulate the light to enable independent communication (courtesy of Intel Corp).

In addition, many aspects of the eight-wavelength integrated laser array technology are being implemented by Intel’s Silicon Photonics Products Division as part of a future optical compute interconnect chiplet product. The forthcoming product will offer power-efficient, high-performance multi-terabits per second interconnect between compute resources including CPUs, GPUs and memory. The integrated laser array is a critical element to achieve a compact and cost-effective solution that supports high-volume manufacturing and deployment, says Intel.

Intel Research Center for Integrated Photonics for Data Center Interconnects opened