News: Optoelectronics

13 April 2023

Annealing InP quantum dot MBE structures for laser diodes

Researchers in the USA report progress in molecular beam epitaxy (MBE) and post-growth annealing of indium phosphide (InP) quantum dot (QD) structures for deployment in near-infrared and visible red laser diodes with low threshold current density (Jth) [Pankul Dhingra et al, J. Appl. Phys., v133, p103101, 2023].

“After annealing, Jth per QD layer is 99.8A/cm2, >7x lower than previous reports by MBE and comparable to their MOCVD-grown counterparts,” claims the team from University of Illinois Urbana-Champaign and University of Texas at Austin.

The researchers add: “Among the few reports of the molecular beam epitaxy (MBE) growth of InP QD lasers, the lowest published Jth value is ~2000A/cm2, >10x higher than with MOCVD.”

The low growth temperature of MBE relative to metal-organic chemical vapor deposition (MOCVD) leads to challenges in terms of optical quality of the complete epitaxial structure, which included quaternary aluminium gallium indium phosphide (AlGaInP) alloy barriers for the InGaP quantum wells (QWs) in which the QDs were placed.

The team reports: “InP/AlGaInP QDs show greater thermal stability, with ~50x increase in the PL intensity due to improvement in the optical properties of InP QDs, InGaP QWs, and AlGaInP barriers. Thermal annealing is a crucial step toward developing visible red lasers that will allow integrated photonics to expand into areas such as quantum computing, optogenetics, and next-generation displays.”

The researchers add: “While the atomic origin of the improvement remains unclear, deep-level transient spectroscopy studies of InGaP/AlGaInP QWs show a substantial reduction of signals related to phosphorous vacancy complexes after rapid thermal annealing (RTA) at 875°C.”

The attraction of MBE is that it allows easier growth control of the QD layers themselves. In MOCVD, the substrates need to be offcut to encourage high dot density with uniform size.

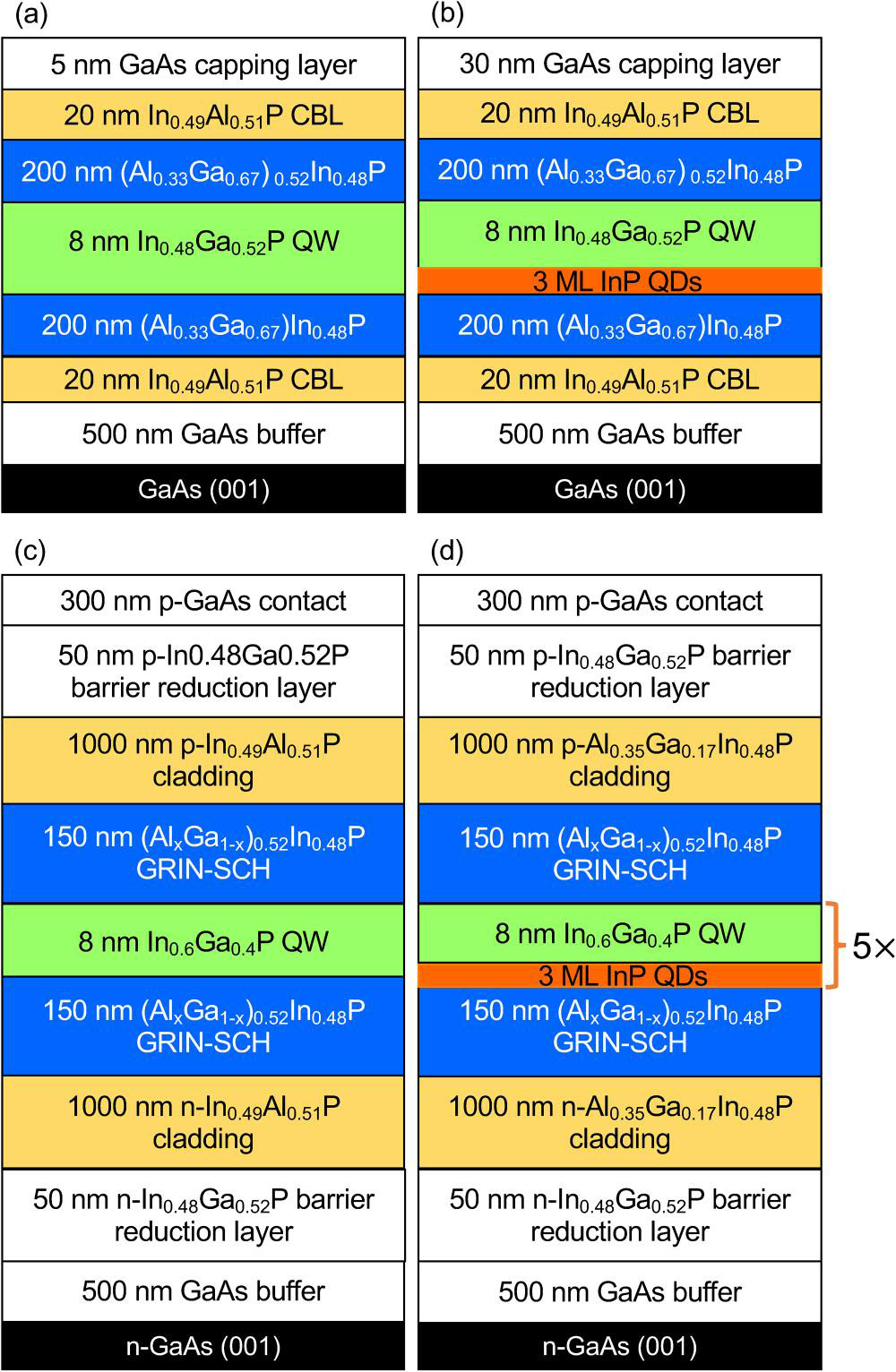

Figure 1: PL structure schematics for (a) In0.48Ga0.52P QW and (b) InP QDs grown on GaAs (001) substrates. Laser design for (c) In0.6Ga0.4P SQW and (d) InP MQD graded-index separate-confinement heterostructure (GRIN-SCH) lasers.

The researchers grew four solid-source MBE structures on gallium arsenide (GaAs) (001) substrates with a view to photoluminescence (PL) and laser diode (LD) experiments (Figure 1). The substrate temperature during the growth was 460-480°C. The V/III ratio was in the range 15-30.

For the PL experiments, the protective GaAs capping layer was removed by etching. The QW and three monolayer (ML) QD active regions were sandwiched between carrier-blocking layers (CBLs) consisting of undoped indium aluminium phosphide (InAlP) to reduce surface recombination. The well barriers were AlGaInP rather than the more usual InGaP.

These layers translated with suitable doping and thickness/composition adjustments into suitable components of the laser diodes. Some of the adjustments aimed at creating compressive strain in the QW — rather than the unstrained condition of the PL structure — with a view to reducing the threshold current of the broad-area stripe lasers with 800–1560μm cavity lengths. The laser mirror facets were uncoated.

The PL study focused on tuning the post-growth annealing, aiming at high-intensity, stable wavelength emission from the structures. The team performed comparisons based on rapid thermal annealing (RTA) and furnace annealing (FA) techniques. The use of quaternary AlGaInP barriers reduced indium out-diffusion, enabling longer annealing times at higher temperature.

Laser diodes fabricated from the single-quantum-well (SQW) epitaxial material had 1.5x reduced threshold current density, from 340 to 200A/cm2, after RTA at 950°C for 1s. Using a heat-sink, the threshold current was maintained at 200A/cm2 even in continuous-wave operation, “among the lowest reported values for In0.6Ga0.4P SQW lasers by any growth technique”, the team points out. The RTA blue-shifted the as-grown emission wavelength from 690nm to 683nm.

The researchers comment: “Changes in the emission wavelength can be attributed to group-III intermixing after RTA, heating of the active region at high current density, and current-induced wavelength shift, typically observed in broad-area lasers.”

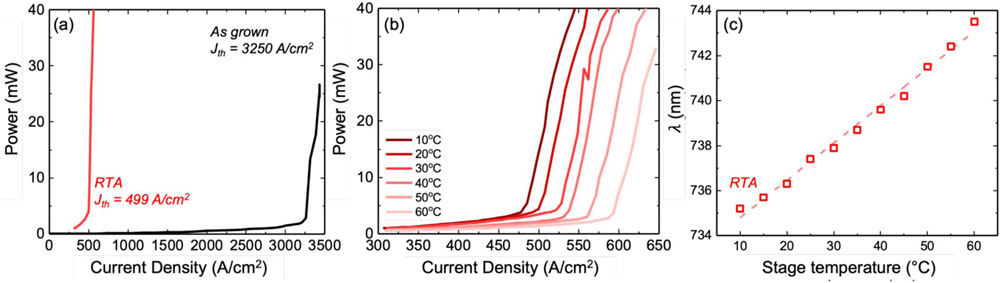

The same RTA process reduced the threshold current density by 6.5x, from 3250A/cm2 to 499A/cm2, in the multiple quantum dot (MQD) laser structures (Figure 2). Measurements of the threshold between 10°C and 60°C gave a characteristic temperature of 230K for the RTA laser diodes, representing an increase from 477A/cm2 to 586A/cm2 with temperature.

Figure 2: (a) Pulsed light output power–current density characteristics of InP MQD laser at room temperature. (b) Temperature-dependent performance. (c) Temperature dependence of emission wavelength.

The researchers comment on the temperature-dependent measurements, “there are no previous reports describing the high-temperature operation of MBE-grown InP QD lasers for comparison to these results.”

The near-infrared (NIR) wavelength of the RTA MQD lasers also red-shifted with temperature. The as-grown InP MQD lasers did not operate past 20°C.

Unspecified “further improvements in the fabrication” and heat-sinking enabled continuous-wave operation of annealed MQD lasers with 565A/cm2 threshold.

The researchers expect similar performance gains from furnace annealing, based on their PL studies.

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.