News: Suppliers

14 August 2023

US Department of Energy releases 2023 Critical Materials Assessment

The US Department of Energy (DOE) has released its 2023 Critical Materials Assessment, which evaluated materials for their criticality to global clean energy technology supply chains and has hence determined the 2023 DOE Critical Materials List of energy-specific critical and near-critical materials through 2035.

The Assessment focuses on key materials with high risk of supply disruption that are integral to clean energy technologies. The final list includes aluminium, cobalt, copper, dysprosium, electrical steel (grain-oriented steel, non-grain-oriented steel, and amorphous steel), fluorine, gallium, iridium, lithium, magnesium, natural graphite, neodymium, nickel, platinum, praseodymium, terbium, silicon, and silicon carbide.

Gallium (Ga) continues to be critical due to its use in light-emitting diodes. In addition, the use of gallium has increased both in magnet manufacturing and in semiconductors including gallium arsenide (GaAs) or gallium nitride (GaN), the Assessment notes.

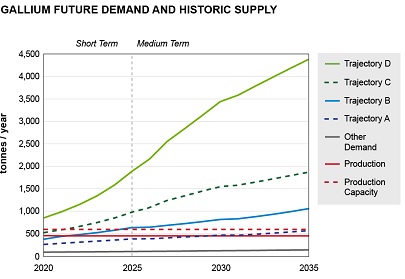

The Figure shows four different demand scenarios for gallium from 2020 to 2035 against current gallium production and production capacity. Energy applications considered for gallium were LED lighting, magnets in electric vehicles (EVs) and wind turbines, solar cells, and power electronics.

There is a wide gap among the four trajectories due to different technology trends. LED demand is steadily growing for both low and high trajectories. Gallium demand for magnets in EVs and wind is highly variable because of the difference between low and high intensities. In the case of solar, because the adoption of copper indium gallium diselenide (CIGS) is shrinking, trajectories A and B assume no CIGS market share between 2020 and 2035, while trajectories C and D assume 5% CIGS market share within the same time frame. Overall, demand for gallium in energy applications is the dominant use of gallium. Other demand not considered in the report includes the use of gallium in consumer electronics and telecommunications. As the Figure shows, ‘other demand’ is insignificant.

Production data were obtained from the United States Geological Survey (USGS). Of this data, high-purity refined gallium production was identified as the material form of interest due to the requirement that most semiconductor applications feature 6N purity or higher (IARC). To compute total high-purity gallium production capacity, the primary high-purity gallium production capacity 325mt was summed with the secondary high-purity gallium production capacity 273mt (USGS). Regarding current production, because recycling output is not available, an assumed 86% capacity utilization rate was used to derive production from capacity. This number, 232mt, was then added to primary high-purity gallium production, 220mt, to compute the total supply of high-purity gallium.

“As our nation continues the transition to a clean energy economy, it is our responsibility to anticipate critical material supply chains needed to manufacture our most promising clean energy generation, transmission, storage and end-use technologies, including solar panels, wind turbines, power electronics, lighting, and electric vehicles,” says Alejandro Moreno, acting assistant secretary for the DOE’s Office of Energy Efficiency and Renewable Energy (EERE). “Ultimately, identifying and mitigating material criticality now will ensure that a clean energy future is possible for decades to come.”

Because material and technology markets are global, the Critical Materials Assessment has a global scope, placing US domestic interests in that context. For each of the critical materials identified, the DOE says it will develop an integrated strategy to address material-specific risks.

The 2023 Critical Materials Assessment was managed and funded by EERE’s Advanced Materials and Manufacturing Technologies Office (AMMTO) and was conducted by Argonne National Laboratory and Idaho National Laboratory, in consultation with members of the DOE Critical Minerals and Materials Science and Energy Technology Team.