News: LEDs

14 July 2023

Improving micron-scale AlGaInP red LED performance

University of California Santa Barbara (UCSB) in the USA and Seoul Viosys Co Ltd of South Korea have used a combination of thermal annealing, chemical treatment, and passivation, to reduce performance degradation in micron-scale aluminium gallium indium phosphide (AlGaInP) red light-emitting diodes (LEDs) [Applied Physics Express, v16, p066503, 2023]

The researchers report: “The devices with sidewall treatments demonstrated a reduction in external quantum efficiency (EQE) of 20%, corresponding to the lowest efficiency drop due to the size effect in AlGaInP μLEDs to date.”

Micron-scale LEDs are being developed for display applications. Although nitride-based InGaN LEDs are used to cover the green and blue parts of the visible color range, InGaN red LEDs suffer from much reduced efficiency and low light output powers. Normal red LEDs use other material systems such as AlGaInP.

Unfortunately for micron-scale applications such as displays, the reduced-size AlGaInP LEDs suffer from more severe efficiency degradation than nitride-based devices.

This mainly arises from ‘sidewall damage’ from the mesa etching part of the LED fabrication process. This damage has a larger impact on smaller devices due to the greater ratio of sidewall surface area to device volume — or, alternatively but equivalently, sidewall perimeter to device area.

Damaged sidewalls form sites where carriers more easily dissipate their energy through Shockley–Read–Hall (SRH) recombination, rather than perform the desired LED function of recombining electrons and holes into photons. AlGaInP devices suffer from further factors of a longer minority carrier diffusion length, and faster surface recombination velocity, compared with other LED materials systems, which means that the carriers can more easily end up at the sidewalls, avoiding photo-production.

Figure 1: Schematics of AlGaInP devices with no sidewall treatments (reference), with ALD sidewall passivation, and with combination of chemical treatments and ALD sidewall passivation.

The devices (Figure 1) were fabricated from one commercial 4-inch AlGaInP wafer produced for LED production. The active light-emitting region of the epitaxial material comprised 40 AlGaInP quantum wells in InGaP barrier layers.

The material was diced into 1.5cmx1.5cm squares for LED fabrication. A 110nm indium tin oxide (ITO) transparent ohmic conductor was first applied to the p-GaP contact layer by electron-beam evaporation.

Various-sized square device mesas of sides from 20μm to 100μm were etched using reactive chlorine/nitrogen ions. A major problem with reactive-ion etching is that it creates highly defective sidewalls.

The researchers tackled the sidewall damage by a combination of annealing, chemical treatment, and passivation. The chemical treatment consisted of 310°C rapid thermal annealing in nitrogen for 5 minutes and 60°C ammonium sulfide ((NH4)2S) exposure for 10 minutes. The passivation came from atomic layer deposition (ALD) of aluminium oxide (Al2O3).

The devices were completed by applying an omnidirectional reflector (ODR) and electrical isolation materials, and metal electrodes. The ODR consisted of a three-period silicon dioxide/tantalum pentoxide (SiO2/Ta2O5) structure. The electrical isolation was Al2O3. The contact metals consisted of annealed germanium/gold/nickel/gold (Ge/Au/Ni/Au).

The researchers also produced reference devices without any attempt to repair the sidewall damage, and devices with only passivation, but no chemical treatment step.

The ALD passivation improved the electrical current–voltage performance of the LEDs, reducing series resistance and leakage currents. The reference device without passivation also had a higher subthreshold current.

While the annealing and chemical treatment had no visible effect on the electrical performance, the light output power and external quantum efficiency were significantly increased. For 20μm-side devices, the light output was 5x that for the reference LEDs without any sidewall treatments at 5A/cm2 injection. The effect of chemical treatment over just applying the ALD passivation was 1.9x at 100A/cm2.

The researchers also found a significant effect on performance from applying thermal annealing before the ammonium sulfide treatment. In particular, the EQE improved by 160% and 40% at 5A/cm2 and 100A/cm2, respectively.

The team comments: “The purpose of thermal annealing was to remove residual oxygen at the surfaces before the chemical treatment with ammonium sulfide, and the thermal annealing condition was insufficient for nitridation to occur. The large enhancement in optical power was attributed to the reduction in SRH non-radiative recombination centers at the active region, resulting in an improvement in internal quantum efficiency.”

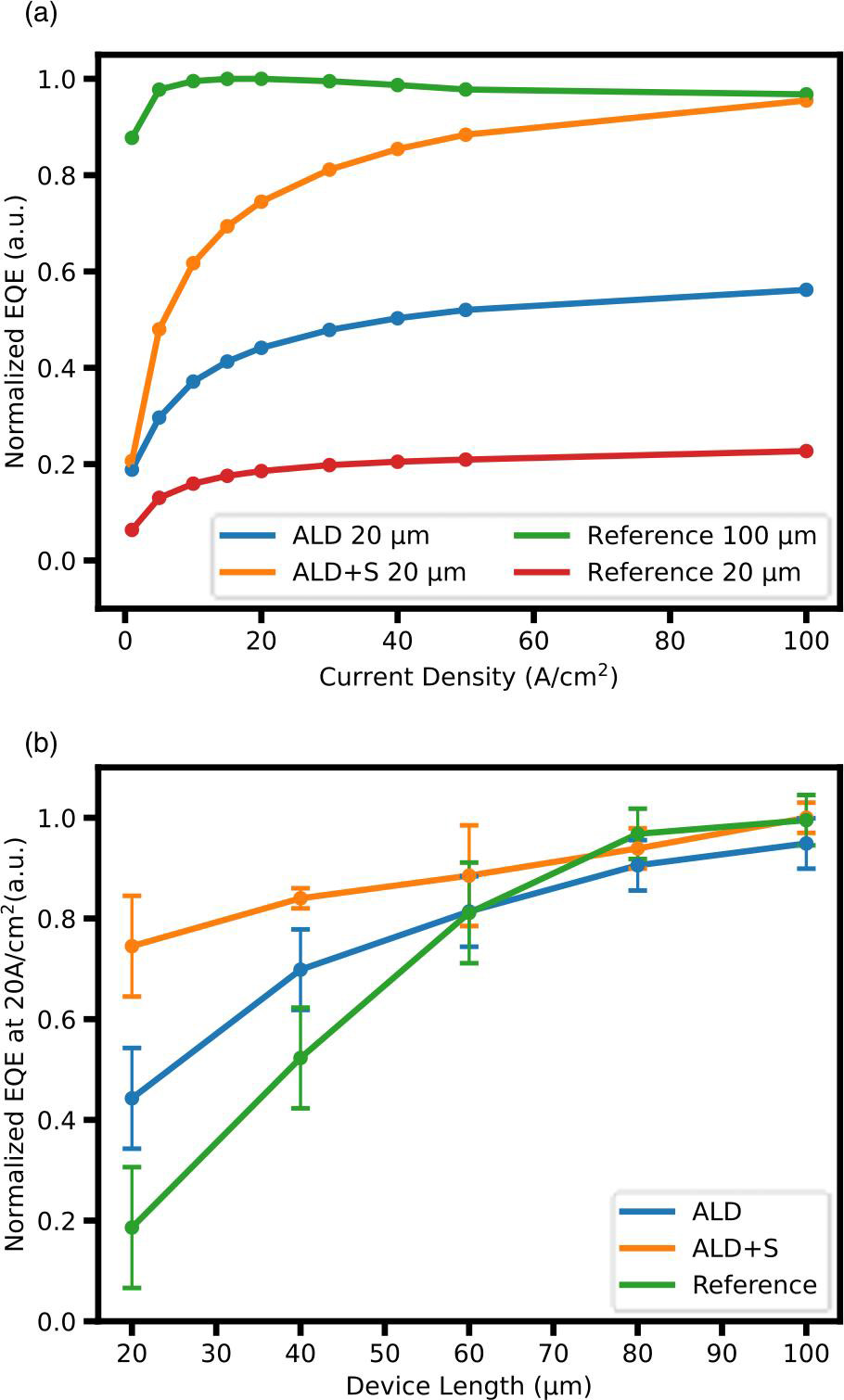

At 100A/cm2 injection, the fully treated and passivated 20μm-side device showed comparable performance to the larger 100μm-side reference without any sidewall measures (Figure 2). The 20μm-side devices without chemical treatment and the reference were reduced in EQE by 50% and 80%, respectively.

Figure 2: (a) On-wafer EQE performance of AlGaInP LEDs and (b) on-wafer EQE measurements of AlGaInP devices with and without thermal annealing before treating with ammonium sulfide with various side mesas.

At 20A/cm2 injection, the reduction in EQE relative to the largest 100μm-side LEDs was around 20% for the fully treated device. “The 20% reduction in EQE indicates that additional optimizations in the sidewall treatments are necessary to achieve fully size-independent EQE performance, yet this work demonstrates AlGaInP μLEDs efficiency can be significantly improved with proper sidewall treatment techniques,” the team writes.

The devices showed similar EQE degradation effects from increasing the operating temperature up to 80°C. The researchers explain: “The thermal degradation in EQE of AlGaInP devices was attributed to the direct–indirect bandgap transition and carrier overflow due to the smaller band offset compared to III–nitride-based devices. This suggested that the thermal degradation in EQE is limited by the intrinsic material properties and epitaxial design and sidewall defects do not contribute to additional EQE loss.”

At 80°C, the light output power from the fully treated 20μm LEDs was 20% and 15% greater than that from the same sized reference and passivation-only devices, respectively.

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.