News: Suppliers

1 November 2023

ELEMENT 3–5’s novel ACCELERATOR 3500K provides single-crystal AlN for mass production

ELEMENT 3–5 GmbH says that its innovative Next Level Epitaxy (NLE) technology enables the reduction of the total manufacturing cost, energy and environmental impact of light-emitting diodes (LED), high-electron-mobility transistor (HEMT) for high-power applications, and life-time expanding layers in batteries.

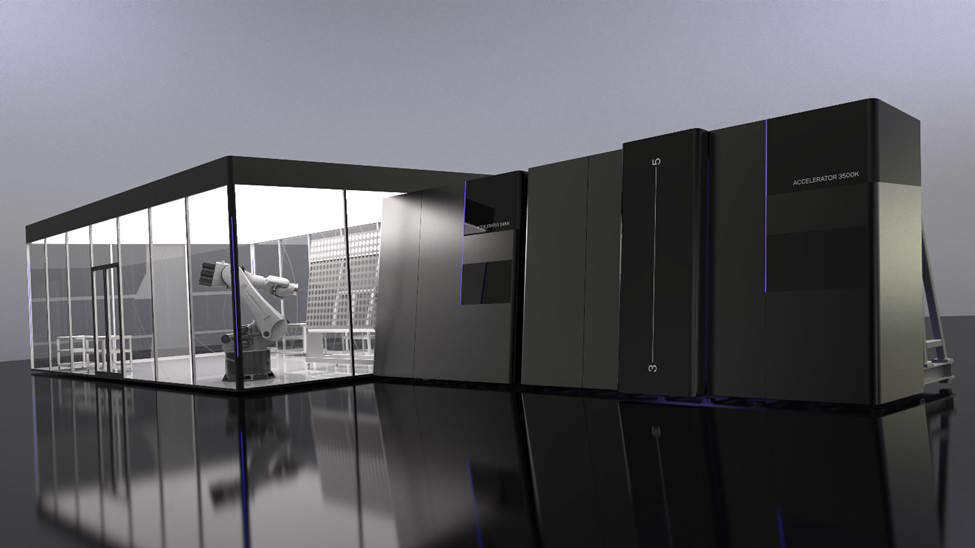

The Baesweiler (Germany) based company has unveiled its ACCELERATOR 3500K for the mass production of aluminium nitride (AlN) epitaxial thin films as starting layer on silicon, sapphire or silicon carbide (SiC).

The ACCELERATOR 3500K is said to represent a paradigm shift in the production of wide-bandgap semiconductors. The epitaxy system follows a modular design and is for the first time in-line ready — it includes the carrier loading, substrate cleaning followed by growth of single-crystal AlN layers.

Photo: ELEMENT 3-5´s ACCELERATOR 3500K.

“The ACCELERATOR 3500K lives up to its’ name. The system accelerates the production on the customer side significantly.

It is equipped with combined plasma sources and ion gun enabling the fabrication of AlN layers characterized by single-crystal quality at processing temperatures below 300°C that enable a 90% saving in energy consumption,” says ELEMENT 3–5’s managing director Dr Volker Sinhoff. “Additionally, its wafer carrier is designed to accommodate 35 x 300mm, 70 x 200mm, 135 x 150mm or 300 x 100mm wafers during each processing cycle, making a tenfold increase in capacity compared to a conventional metal-organic chemical vapor deposition (MOCVD) reactor. Compared with the MOCVD process the incorporation efficiency of the molecules is distinctly higher (from 35% to >80%), which leads to significantly reduced consumable costs. In addition, metal-organic compounds and toxic gases are avoided completely. All in all, an advantageous solution for the user to enter new markets like micro-LEDs for displays or in mature markets like GaN LED and GaN power (HEMT).

The mini- and micro-LED boom is just getting started and we expect a steep rise in the HEMT market in the future, supported by our Next Level Epitaxy,” he adds. “Customers anticipate even greater performance while also guaranteeing cost-effectiveness. We provide customers with the ability to take the pole position with the help of our cutting-edge technology.”

ELEMENT 3–5 says that it is setting a new epitaxy standard, enabling the customer to have a completely new option: single-crystal layer qualities, superior layer homogeneity, and stable thickness repeatability paired with over 70% reduced productions costs, reduced CO2 footprint and MOCVD capacity increase is included for free.