News: LEDs

24 July 2024

Nanoparticle-based zinc oxide homojunction LEDs

Shimane University and S-Nanotech Co-Creation Co Ltd in Japan report on phosphor-converted full-color and white-light emission from zinc oxide (ZnO) pn homojunctions, using p-ZnO nanoparticles (NPs) from an arc-discharge process [Phys. Status Solidi RRL, p2400149, 2024].

Hole injection from bulk ZnO is difficult to arrange as there is no effective acceptor doping process known at present. Even without doping, ZnO is n-type conducting. Some attempts at producing pn heterojunctions have been reported, but homojunction structures should benefit from reduced strain and result in better efficiency devices in general.

The Shimane/S-Nanotech team suggests that reducing the effective dimension of the ZnO might enhance the p-type doping effect of nitrogen, which has been found in previous studies.

The researchers explain: “Low-dimensional p-type ZnO is relatively easier to fabricate than thin films, and its use in LEDs, as compared to the use of planar films, provides several benefits. Low-dimensional p-type ZnO can be used to readily confine carriers within one-dimensional structures, thus enhancing the junction area and minimizing the dependency on temperature sensitivity. Thus, several attempts have been made to fabricate low-dimension ZnO-based LEDs.”

The use of p-ZnO nanoparticles could widen the optoelectronic potential of ZnO for light-emitting diodes (LEDs), photodetectors, solar cells, transparent conductive oxides, and lasers. A particular attraction of ZnO for white and visible color emissions, compared with the mainstream indium gallium nitride (InGaN) devices is the much lower cost of the base Zn material, relative to the extremely rare In and Ga elements.

The nanoparticles were fabricated in a plasma chamber using an electric arc formed between a pointed carbon cathode and a flat zinc ingot anode in an oxygen/nitrogen (O2/N2) atmosphere at 150Torr pressure when biased above the striking/ignition voltage. The relatively low pressure enabled a lower striking voltage with a cathode–anode separation of around 1mm. The arc ionized the gas molecules and created free electrons. Some of the electrons recombined with the ions to give a purplish glow in the plasma chamber. The arc current was 50A DC.

The researchers report: “The ionized gases produced in an arc discharge are accelerated by an electric field and combine with the incoming cooled gas (a mixture of O2 and N2) to form ZnO nuclei, which subsequently grow into nanorods or nanoparticles as they impinge on the cooled walls of the plasma chamber and are rapidly quenched.”

The ZnO NPs contained N impurities. Photoluminescence studies suggested that the dominant incorporation was of single-atom N replacing O (NO) in the ZnO wurtzite lattice, rather than diatomic N2 incorporation as (N2)O. The NO form should act as an acceptor, while (N2)O is expected to be a double donor.

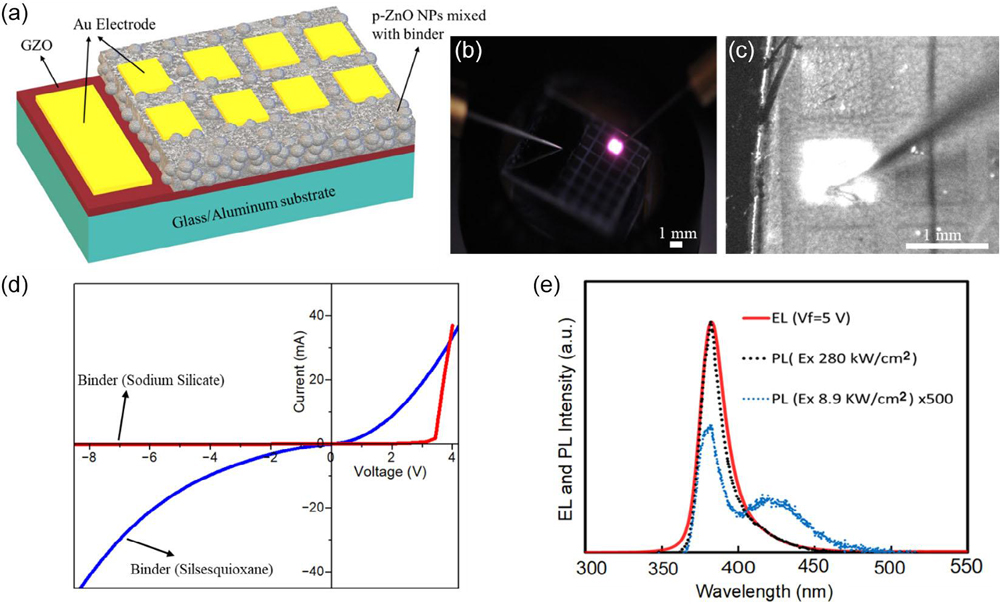

The researchers fabricated LEDs with the p-ZnO nanoparticles on gallium-doped n-ZnO (GZO) layer on aluminium (Al)/glass substrates (Figure 1). The GZO was applied by sputtering. The p-ZnO nanoparticles from the arc-discharge process were spin-coated with the binder onto the GZO. After annealing at 300°C, the p-ZnO nanoparticle layer was 3µm thick. Gold (Au) was used for the electrodes. The turn-on voltage was around 3.4V, corresponding to the ZnO bandgap of 3.37eV.

Figure 1: a) Scheme for ZnO nanoparticle-based LED. Photographic images: b) UV emission at 8V bias captured using CCD camera with ultraviolet/infrared (UV/IR) filter removed; c) UV emission detected by UV-sensitive monochrome camera. d) Current-voltage characteristics of LEDs, and e) EL and PL spectra of ZnO nanoparticle layer.

The electrical performance depended on the binder layer holding the ZnO nanoparticles. The researchers report that using sodium silicate (Na2SiO3) gave much reduced leakage under reverse bias, compared with silsesquioxane. The team suggests that Na2SiO3 provides a better means to passivate defects. The rectification on/off ratio at ±4V was 1600 for devices with the preferred Na2SiO3 binder.

The electroluminescence (EL) from the device biased at 5V gave a narrow spectral line around 383nm wavelength with 23nm full-width at half maximum (FWHM) from near-band-edge emissions.

The intensity of the EL peaked under 25mA current injection. The reduced intensity at higher currents is attributed to self-heating effects. The self-heating also seemed to red-shift the peak wavelength in the longer-wavelength direction.

The researchers comment: “The red-shift may be attributed to thermally induced bandgap narrowing or a change in the carrier concentration caused by varying the injection current.” The higher temperature may also decay the possibility of excitons (electron–hole bound states), further reducing EL intensity.

The researchers used a Peltier electrothermal module to control the LED temperature. Above 30°C operating temperature the EL intensity was much reduced.

The team also studied the application of phosphors with a view to RGB color emission and white-light illumination.

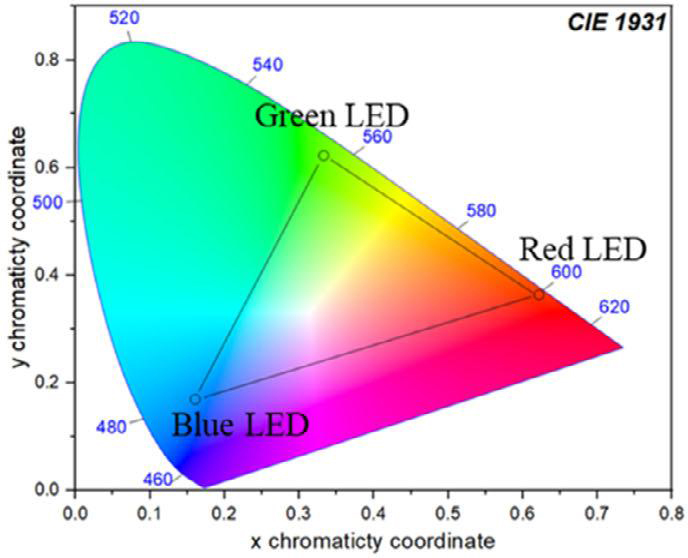

Figure 2: Color gamut obtained by applying RGB CASN, SiAlON and SBCA phosphors, respectively.

For RGB emissions (Figure 2), the researchers applied three europium-doped phosphor types in UV-curable resin: red-emitting CASN calcium aluminium silicide nitride (CaAlSiN3:Eu2+), green β-SiAlON silicon aluminium oxynitride ((Si,Al)3(O,N)4:Eu2+), and blue SBCA ((Sr,Ba)10(PO4)6Cl2:Eu2+).

The researchers comment: “The gamut area can be further enhanced by selecting phosphors with a higher saturation. Furthermore, the residual UV light from the LEDs can be reduced using a UV filter or by increasing the phosphor thickness to optimize visible light.”

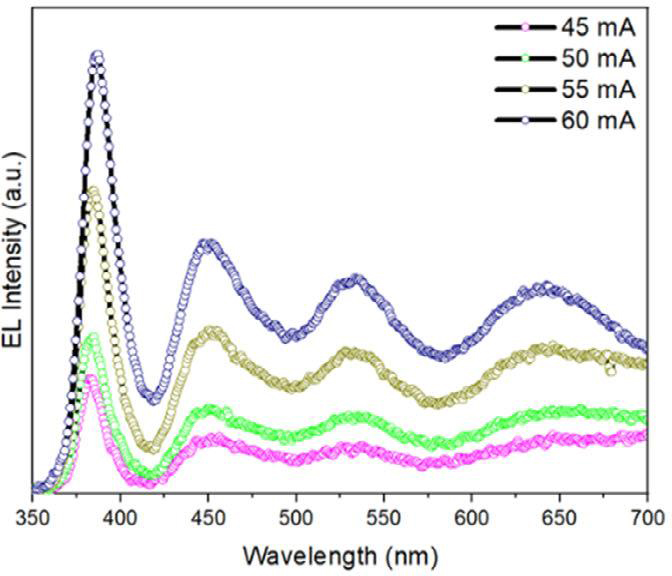

A phosphor blend was applied to give phosphor-converted white LED (pc-WLED) emission (Figure 3) with a chromaticity coordinate of (0.32,0.33). The average color rendering index (Ra) was 90, and the color temperature of 6226K is described as ‘cool white’.

Figure 3: WLED EL spectra with variable injection current.

The researchers comment: “Increasing the injection current for the WLED resulted in negligible peak shifts for the three visible wavelengths (red, green, blue), which led to the high chromatic stability of the pc-WLED.”

The color fidelity (Rf) was 93; the color gamut (Rg) was 106.

Zinc oxide homojunction LEDs ZnO InGaN LEDs

https://doi.org/10.1002/pssr.202400149

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.