News: Microelectronics

14 October 2024

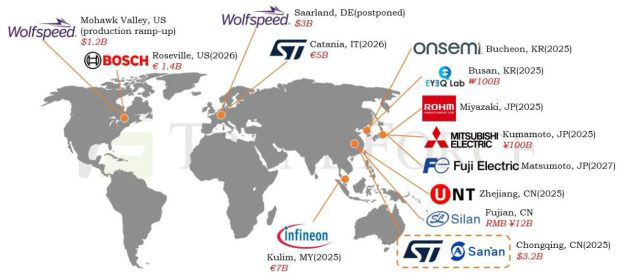

Planned 8-inch silicon carbide wafer fabs worldwide reach 14

Over the past few years, major companies around the world have been investing in 8-inch silicon carbide (SiC) production lines, and these investments are now gradually becoming operational, notes market research firm TrendForce in a recent summary.

Global spread: 14 new 8-inch silicon carbide factories

Globally, companies such as STMicroelectronics (ST), Onsemi, Infineon, Wolfspeed, ROHM, BOSCH, Fuji Electric, Mitsubishi Electric, Vanguard International Semiconductor (VIS) and EPISIL, Silan Microelectronics, and UNT have all announced plans to build 8-inch SiC chip factories. Many of these companies are also making strides in the upstream substrate and epitaxial material segments, TrendForce adds.

STMicroelectronics (ST): On 31 May, ST announced the construction of a new 8-inch SiC plant in Catania, Italy, consolidating all aspects of the SiC production process. The new plant is expected to start production in 2026 and reach full capacity by 2033, with a maximum capacity of 15,000 wafers per week and an estimated total investment of about €5bn.

The 8-inch SiC manufacturing plant in Chongqing, China, jointly established by ST and China’s Sanan Optoelectronics, will become ST’s third SiC production center. The project was announced in June 2023 and is expected to begin production in fourth-quarter 2025, with full completion anticipated by 2028.

Onsemi: Onsemi’s SiC wafer plant in Bucheon, South Korea, completed its expansion in 2023 and plans to transition to 8-inch production by 2025 after completing technology verification. By then, capacity will be expanded to 10 times the existing scale.

Infineon: It was announced on 8 August that the first phase of Infineon’s 8-inch SiC power semiconductor wafer plant in Kulim, Malaysia, has officially started operation, with large-scale production expected by 2025.

Wolfspeed: Wolfspeed has the world’s first and largest 8-inch SiC plant, located in Mohawk Valley, New York, which officially opened in April 2022. As of June 2024, the factory has achieved a 20% wafer utilization rate.

In January 2023, Wolfspeed and automotive parts supplier ZF announced plans to build the world’s largest and most advanced 8-inch SiC device manufacturing factory in Saarland, Germany. This project has been delayed and is now expected to start at the earliest in 2025.

ROHM: ROHM built a new SiC plant in Chikugo, Fukuoka Prefecture, Japan, which began mass production in 2022 and plans to transition from 6-inch to 8-inch wafer production by 2025. In July 2023, ROHM announced plans to start producing 8-inch SiC substrates at its second factory in Miyazaki Prefecture, Japan, by the end of 2024.

BOSCH: BOSCH’s factory in Reutlingen, Germany, began 6-inch SiC wafer production in 2021, with 8-inch SiC wafers currently also produced at this factory. The factory in Roseville, CA, USA, is expected to start 8-inch SiC wafer production by 2026.

Mitsubishi Electric: It was announced in late May that Mitsubishi Electric’s 8-inch SiC plant in Kumamoto Prefecture, Japan, will be completed by September 2025, with production brought forward from April 2026 to November 2025.

Fuji Electric: In January, Fuji Electric announced a 200bn yen investment over the next three years (fiscal 2024–2026) for SiC power semiconductor production, including an 8-inch SiC capacity at its Matsumoto factory in Japan, expected to start production in 2027.

UNT: China-based United Nova Technology (UNT) has built its first 8-inch SiC MOSFET wafer production line in Yuecheng District, Shaoxing, and completed the engineering batch in April this year, with mass production expected in 2025.

Silan Microelectronics: Silan officially launched China’s first 8-inch SiC power device chip manufacturing line project in Xiamen on 18 June this year, with a total investment of RMB12bn. The project will be built in two phases, with an annual production capacity of 720,000 8-inch SiC power device chips. The first-phase investment is RMB7bn, which is expected to complete initial connection by the end of third-quarter 2025, with trial production in fourth-quarter 2025 and an annual yield target of 20,000 wafers. The second-phase investment is about RMB5bn.

Vanguard International Semiconductor (VIS) & EPISIL: On 10 September, VIS announced a plan to invest NTD2.48bn to acquire a 13% stake in EPISIL. The two companies will collaborate on the development and production of 8-inch SiC wafer technology, with mass production expected in second-half 2026.

Thailand’s first SiC factory: Recently, the FT1 Corp joint venture in Thailand invested THB11.5bn (US$350m) to build Thailand’s first SiC factory using technology transferred from a Korean chip manufacturer to produce 6-inch and 8-inch wafers. The factory is expected to start production in first-quarter 2027 to meet the growing demand in automotive, data-center and energy storage markets.

Summary

Of the above-mentioned 14 silicon carbide factories (12 under construction), only Wolfspeed’s Mohawk Valley plant can currently provide 8-inch SiC wafers in the short term. Other manufacturers are expected to begin supplying 8-inch SiC wafers gradually from next year, concludes TrendForce.

ST remains largest silicon carbide power device maker, with 32.6% market share

Silicon carbide power device market to grow to $5.33bn in 2026