News: Microelectronics

11 September 2024

Infineon pilots first 300mm power GaN wafer technology on existing large-scale 300mm silicon line

Infineon Technologies AG of Munich, Germany has developed what it says is the first 300mm power gallium nitride (GaN) wafer technology to be applied in an existing and scalable high-volume manufacturing environment, helping to drive the market for GaN-based power semiconductors. Compared with 200mm-diameter wafers, 300mm wafers allow the production of 2.3 times more chips per wafer.

GaN-based power semiconductors are finding fast adoption in industrial, automotive, and consumer, computing & communication applications, including power supplies for AI systems, solar inverters, chargers and adapters, and motor-control systems. GaN manufacturing processes lead to improved device performance, resulting in benefits in end-customers’ applications as it enables efficiency performance, smaller size, lighter weight, and lower overall cost. Furthermore, 300mm manufacturing also ensures superior customer supply stability through scalability.

“The technological breakthrough will be an industry game-changer and enable us to unlock the full potential of gallium nitride,” reckons CEO Jochen Hanebeck. “Nearly one year after the acquisition of GaN Systems, we are demonstrating again that we are determined to be a leader in the fast-growing GaN market. As a leader in power systems, Infineon is mastering all three relevant materials: silicon, silicon carbide and gallium nitride.”

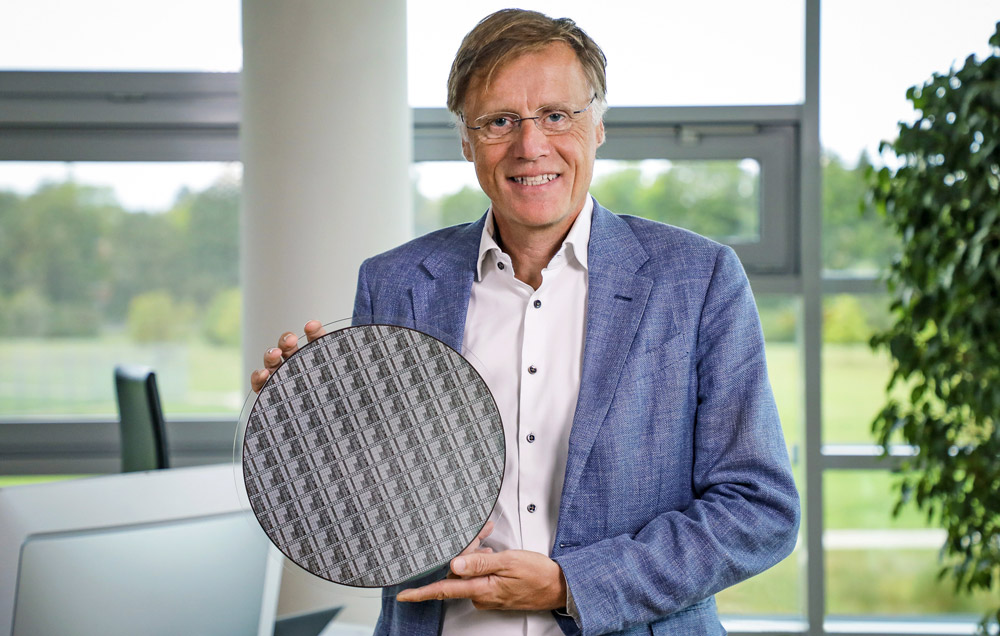

Picture: Infineon CEO Jochen Hanebeck holds one of the world’s first 300mm GaN power wafers produced in an existing and scalable high-volume manufacturing environment.

Infineon manufactured the 300mm GaN wafers on an integrated pilot line in existing 300mm silicon production in its power fab in Villach, Austria. The firm is leveraging well-established competence in the existing production of 300mm silicon and 200mm GaN. It will further scale GaN capacity aligned with market needs. Infineon reckons that 300mm GaN manufacturing will put it in a position to shape the growing GaN market, which is expected to reach several billion US dollars by the end of the decade.

Infineon says it is implementing 300mm GaN to strengthen existing and enabling new solutions and application fields with an increasingly cost-effective value proposition and the ability to address the full range of customer systems. The firm will present the first 300mm GaN wafers to the public at the electronica 2024 trade show in Munich (12-15 November).

A significant advantage of 300mm GaN technology is that it can utilize existing 300mm silicon manufacturing equipment, since gallium nitride and silicon are very similar in manufacturing processes. Infineon’s existing high-volume silicon 300mm production lines are said to be suitable for piloting reliable GaN technology, allowing accelerated implementation and efficient use of capital. Fully scaled 300mm GaN production should contribute to GaN cost parity with silicon regarding on-resistance RDS(on), which means cost parity for comparable silicon and GaN products, it is reckoned.

Infineon launches CoolGaN transistor families built on 8-inch foundry processes