News: Suppliers

8 April 2025

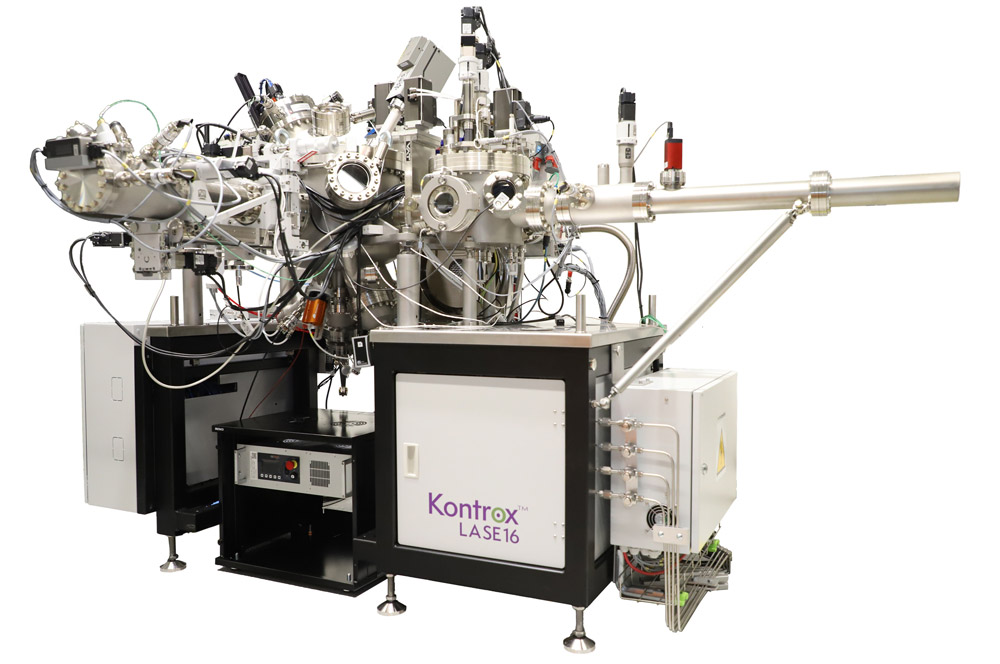

Comptek launches Kontrox LASE 16 for industrial-scale edge-emitting laser facet passivation

Comptek Solutions Oy of Turku, Finland (which specializes in III-V compound semiconductor quantum surface engineering) has launched its industrial-grade Kontrox LASE 16. Following significant advances in optimizing Kontrox technology for passivating edge-emitting lasers, the Kontrox LASE 16 is designed to transform laser facet processing, providing manufacturers with a more efficient and cost-effective solution for enhanced laser diode performance.

As the laser diode market is projected risee at a compound annual growth rate (CAGR) of 10.94% to about US$25.84bn by 2034 (according to Precedence Research), manufacturers are facing increasing demands to improve performance, reliability and scalability, all while maintaining cost-effectiveness. A key challenge in this evolution is addressing catastrophic optical mirror damage (COMD) — a major failure mode caused by oxidation-induced absorption at laser facets.

Industrial-grade Kontrox LASE 16 tackles this challenge by integrating Comptek’s proprietary Kontrox passivation technology, which precisely controls the oxidation process of the compound semiconductor materials used in laser diodes. This process creates a stable crystalline native oxide barrier on the facets, protecting against further oxidation and significantly enhancing laser diode performance. Delivering passivation results that are claimed to be comparable to leading industry standards such as ZnSe and E2 process, Kontrox LASE 16 is said to offer lower cost, reduced technical complexity, higher throughput, and outstanding facet stability over time. Treated facets remain highly stable even after prolonged air exposure following passivation, offering manufacturers greater flexibility by eliminating time constraints for the subsequent mirror coating process.

Designed for high-volume, industrial-scale operations, Kontrox LASE 16 combines several advanced processing techniques, optimized and tuned to effectively clean and passivate laser facets, making it a suitable turnkey solution for mass production. Its compact, user-friendly design integrates multiple processes — cleaning, passivation, and sealing — into a single process chamber. This integration boosts flexibility, accelerates throughput, and reduces operational complexities, driving significant cost and time savings compared with traditional passivation methods, it is claimed.

Other product highlights are cited as:

- High throughput: Processes up to 1800 laser bars per day, with eight stacking jigs for continuous production.

- Enhanced facet stability: Passivated facets remain stable for days, removing time pressure and improving flexibility for mirror coatings.

- Supports multiple recipes: Tailored process recipes for various laser bar designs in one setup, maximizing versatility and efficiency.

“With its industrial-grade readiness, optimized design and unmatched facet stability, the Kontrox LASE 16 delivers significant operational advantages, improving efficiency, reducing complexity, and enabling flexible production timelines,” claims CEO & co-founder Vicente Calvo Alonso.

Comptek says that, during the piloting phase with selected customers, the Kontrox turnkey passivation machine has generated significant interest among laser manufacturers worldwide, leading to multiple requests for proof of concepts and trial runs. With the LASE 16 now available for full commercial deployment, Comptek invites laser chip manufacturers to integrate this passivation solution into their production lines.

Comptek completes installation of Kontrox-powered 200mm wafer pilot line