News: Microelectronics

16 April 2025

Navitas gains automotive qualification of high-power GaNSafe ICs

Gallium nitride (GaN) power IC and silicon carbide (SiC) technology firm Navitas Semiconductor Corp of Torrance, CA, USA has announced that its high-power GaNSafe ICs have achieved automotive qualification for both AEC-Q100 and AEC-Q101, showcasing GaN’s next inflection into the automotive market, it is reckoned.

The high-power GaNSafe 4th-generation family integrates control, drive, sensing and critical protection features that enable what is claimed to be unprecedented reliability and robustness in high-power applications. It is said to be the world’s safest GaN with short-circuit protection (350ns maximum latency), 2kV ESD protection on all pins, elimination of negative gate drive, and programmable slew rate control. All these features are controlled with 4-pins, allowing the package to be treated like a discrete GaN FET, requiring no VCC pin.

The Automotive Electronics Council (AEC) lists various qualifications focused on failure mechanism-based stress tests for packaged integrated circuits (AEC-Q100) and discrete semiconductors (AEC-Q101) used in automotive applications. Navitas’ GaNSafe has been qualified to both standards to ensure that both the discrete power FET stage and the combined IC solution meet these stringent specifications.

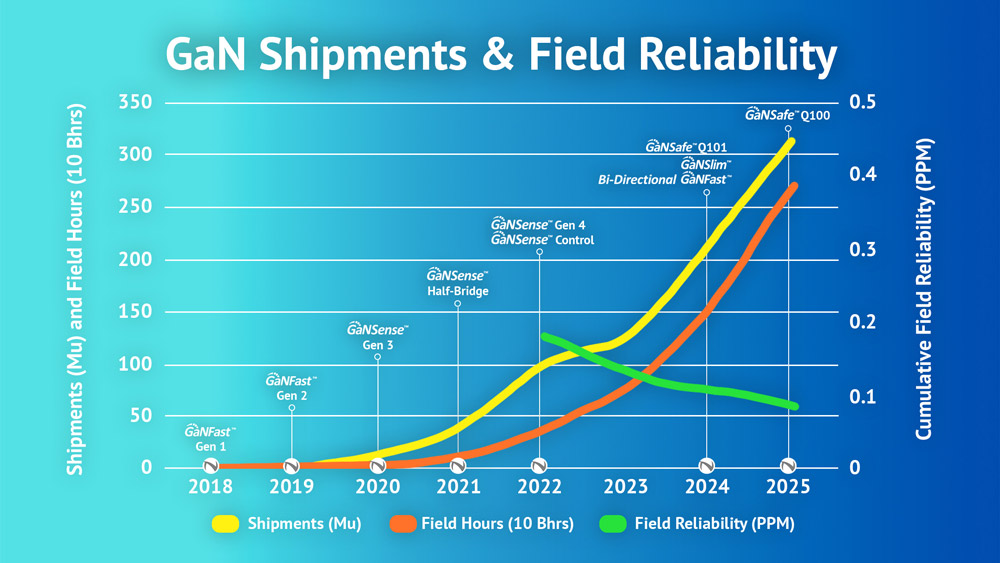

To support the qualification, Navitas has created a comprehensive reliability report that analyzes over seven years of production and field data. It demonstrates their track record, alongside generational and family improvements in robustness and reliability, establishing GaN power ICs as highly reliable and automotive-ready. The reliability report is available to qualified customers.

Additionally in March, Navitas unveiled the first production-released 650V bi-directional GaNFast ICs with IsoFast Drivers, creating a paradigm shift in power to enable the transition from two-stage to single-stage topologies to further enhance efficiency, power density and performance in AC–DC and AC–AC conversion. This would allow next-generation single-stage onboard chargers (OBCs) to provide bi-directional charging in a high-efficiency, extremely compact solution – which eliminates bulky capacitors and input inductors.

A leading electric vehicle (EV) and a solar micro-inverter manufacturer have already begun their implementation of single-stage BDS converters to improve efficiency, size and cost in their systems. GaNFast-enabled single-stage BDS converters achieve up to 10% cost savings, 20% energy savings, and up to 50% size reductions.

Picture: Navitas’ latest GaN reliability report highlights seven years of production with accelerating volumes exceeding 250 million units, while driving field failure rate towards 100ppb.

“Our latest reliability report is the culmination of years of innovation and field experience,” says Gene Sheridan, CEO & co-founder. “With more than 250 million units shipped, over 2 trillion field device hours and a cumulative field failure rate that is now approaching 100 parts per billion, we’re leading the charge in making GaN the go-to technology for EV power systems.”

Navitas adds TOLT package to GaNSafe family