News: LEDs

20 March 2025

OSRAM’s and Nichia’s micro-LED solutions boost resolution 100-fold over traditional matrix LEDs

In its report ‘Automotive MicroLED Comparison 2025’ focusing on the new micro-LED-based technology emerging in the automotive sector, market research and strategy consulting company Yole Group notes that two leading LED companies ams OSRAM and Nichia have developed dedicated micro-LED solutions, enabling more than a 100-fold increase in resolution compared to existing matrix LED systems based on discrete LEDs.

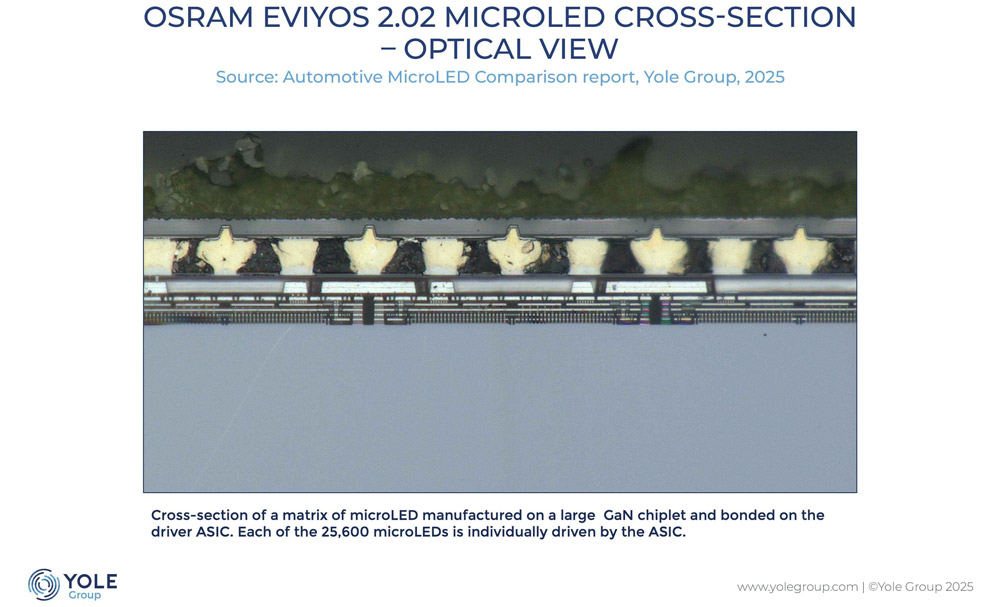

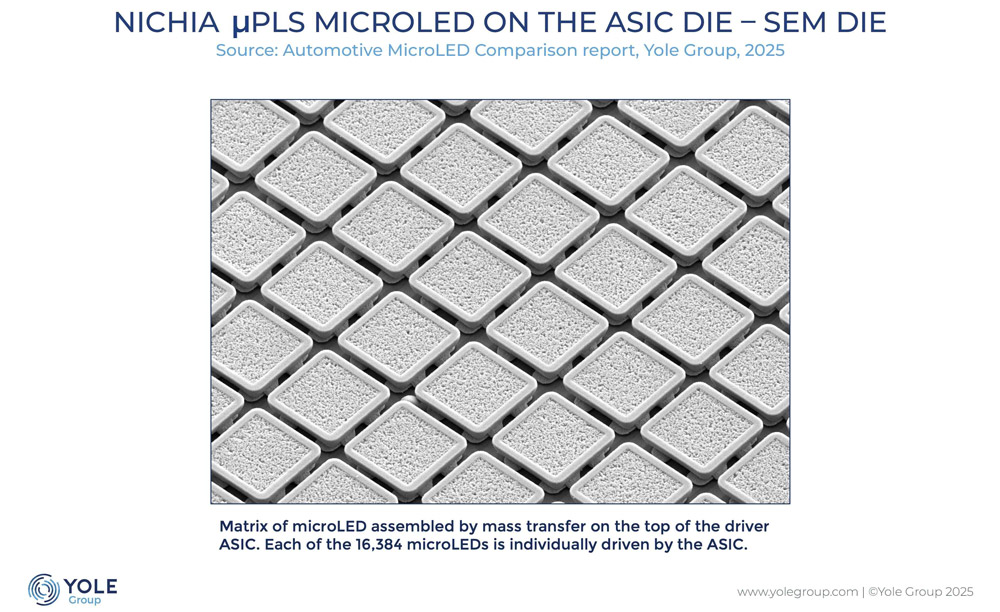

Both components have the same function: an LED matrix for an adaptive driving beam (ADB). However, the technology choice is different, although both solutions are based on micro-LED technology. ams OSRAM has developed a technology to assemble a very large gallium nitride (GaN) chiplet on which 25,600 micro-LEDs are patterned. Nichia has developed a different process based on a mass-transfer technology. 16,380 micro-LEDs are manufactured on a sapphire/GaN substrate and assembled on an ASIC driver die. The two components are assembled in specific packages optimized to enhance thermal management.

The report focuses on the reverse engineering and costing analysis of the first two micro-LED-based products on the market: the EVIYOS 2.0 from ams OSRAM and the µPLS from Nichia. Yole’s investigations underline the technological solutions adopted by both companies. The report examines the complex electrode and mirror structures fabricated on the micro-LED GaN wafer, the micro-LED integration process, and the final assembly & packaging steps.

The Pixel LED EVIYOS developed by ams OSRAM is a pixel-based ADB device for automotive headlights. The reverse costing study provides insights into the technology, manufacturing costs and selling price of the EVIYOS KEW GBBMD1U from ams OSRAM. The KEW GBBMD1U consists of a large-matrix LED die bonded to an ASIC driver die. Each micro-LED, with a 40µm pitch, is directly driven by the ASIC die, allowing for the individual control of all 25,600 micro-LEDs. This pixel ADB solution has been selected by Marelli for its high-end headlamp systems. The EVIYOS 2.0 headlight has been integrated by Marelli into several cars, including VW’s Touareg, Tiguan and Tayron (19kpixels), Opel’s Grandland (25kpixels), and Nio’s ET9 (25kpixels).

“The driver die is designed and manufactured by ams OSRAM at the ams 200 foundry in Austria. ams acquired OSRAM in 2000,” notes Sylvain Hallereau, principal analyst, global semiconductors, at Yole Group. “The LED die is produced by ams OSRAM at their LED foundry in Malaysia. Additionally, based on our reverse engineering and cost analysis, we determined that the gold pad on the driver and the C2W [chip-to-wafer] bonding process are carried out by ams OSRAM in Malaysia. We estimate that the packaging of the driver and LED die is also conducted by ams OSRAM in Malaysia.”

The second component analyzed is the µPLS micro-LED from Nichia, featuring 16,384 pixels. “Nichia’s technology differs significantly, as it is based on the mass transfer of 16,384 individual discrete micro-LEDs onto an ASIC die,” notes Pierrick Boulay, senior technology & market analyst, automotive semiconductors, at Yole Group. “Each micro-LED, with a 50µm pitch, is directly driven by the ASIC die. This pixel ADB solution has been chosen by Forvia Hella for their high-end headlamps.”

Micro-LEDs maintain momentum despite Apple’s withdrawal

Micro-LED IP plateaus after seven years of exponential growth