News: LEDs

6 May 2025

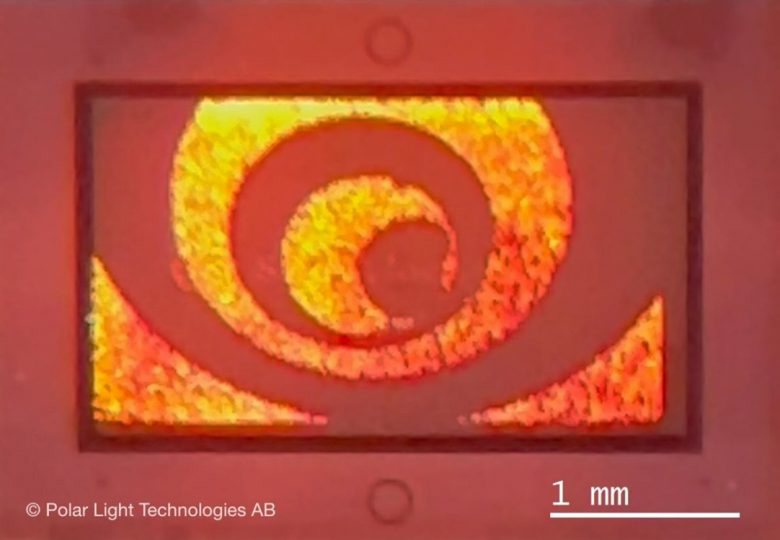

Polar Light demos first pyramidal µLED micro display prototype

Polar Light Technologies AB (PLT) has fabricated its first micro-display prototype built on its proprietary pyramidal micro-LED (µLED), confirming the technology’s ability to integrate the pyramidal micro-LED frontplane onto a CMOS backplane.

Polar Light stems from research by founder professor Per-Olof Holtz and his team at Linköping University (with support from the Swedish Foundation for Strategic Research (SFF) and Sweden’s innovation agency Vinnova). The firm supplies wafer-level RGB micro-LED arrays that can power the next generation of ultra-compact displays.

The prototype pairs a bottom-up-grown Polar Light monochrome µLED front-plane with a high-performance SAPIEN CMOS back-plane. Precision flip-chip bonding was carried out by Finetech of Berlin, Germany (a supplier of sub-micron and high-accuracy die bonding solutions), achieving pixel-accurate alignment across the panel.

“This proof of concept shows that our pyramidal µLEDs can be hybridized to mainstream CMOS drivers, creating a micro-display” notes Polar Light’s co-founder Ivan Martinovic. “We thank our partners SAPIEN Semiconductors and Finetech for helping us validate the manufacturability of our platform.”

This latest achievement provides a path to monolithic RGB displays, based on the red, green and blue µLEDs previously demonstrated using same material system.

Polar Light cites the following factors for why the development I significant:

- Monolithic RGB: Polar Light’s µLEDs, based on the same material system, are paving the way for monolithic RGB displays.

- Integration: The demo display is a stepping stone for Polar Light’s µLEDs to be integrated with a CMOS backplane for novel opto products.

- Bottom-up approach: Pyramidal µLEDs manufactured bottom-up without etching are suitable for integration in VR/AR applications.

- Sub-Lambertian emission: A naturally focused light lobe couples efficiently into waveguide, boosting brightness.

Polar Light is pioneering a patented, bottom-up process that grows pyramidal micro-LEDs atom layer by atom layer, eliminating destructive etch steps that conventional methods require. The result is said to be record small pixels, superior brightness and efficiency, and a manufacturing flow that scales cleanly to high-volume wafers.

Polar Light achieves 625nm-wavelength red pyramidal micro-LED

Polar Light partners with Finetech to connect pyramidal GaN micro-LEDs

Linköping micro-LED spin-off Polar Light Technologies appoints CEO