News: Suppliers

17 September 2025

La Luce Cristallina launches 200mm barium titanate substrate

La Luce Cristallina Inc of Austin, TX, USA has launched its new 200mm (8-inch) crystal-on-glass barium titanate (BaTiO3) substrate and opened a facility to expand capacity for wafer-scale fabrication, supporting growing demand from data-center, telecoms, sensing, computing and integrated photonics markets. With equipment provided by Finland-based manufacturer DCA Instruments, the fab should enable closer collaboration with partners and customers worldwide through a secure US-based supply chain. La Luce Cristallina is now taking orders for its 200mm wafer, with delivery scheduled for early first-quarter 2026.

With the global optical interconnect market expected to rise at a compound annual growth rate (CAGR) of 14.1% to $34.54bn by 2030, La Luce Cristallina says that its 200mm BaTiO3 platform arrives at a critical inflection point for AI and data-center photonics. The 200mm wafer is said to offer better speed, a smaller size and lower power consumption than silicon photonics modulators while addressing the integration challenges of alternative materials.

La Luce Cristallina’s solution delivers a high-performance, foundry-compatible electro-optic platform that supports the capacity demands of AI workloads and high-density optical interconnects. BaTiO3 offers more longevity and multiple generations of device innovation (over 10 years) compared with materials such as lithium niobate, the firm adds, helping customers to prepare for current and future photonics demands while securing quicker and higher returns on their investments. The substrates also support emerging quantum computing, aerospace and defense applications.

La Luce Cristallina leverages RF sputtering to achieve scalable manufacturing, enabling it to produce multiple 200mm wafers per day, far outpacing the manufacturing volume of other methods of producing BaTiO3 on silicon. The firm maintains a secure supply chain, utilizing US-sourced silicon and qualified international partners for silicon-on-insulator (SOI) wafers, ensuring reliable sourcing and mitigating the risks associated with overseas manufacturers. La Luce Cristallina says that its solution integrates cleanly with silicon manufacturing processes and avoids the chemical contamination issues associated with lithium niobate and similar materials. The 200mm wafer is also said to offer better reliability than electro-optic polymers, maintaining optimal performance even under high temperatures, high-frequency operation, radiation and other adverse conditions.

“This new facility represents continued progress in our mission to build a secure US-based supply chain for BaTiO3, helping us serve current and emerging markets across the telecommunications, data-center and defense sectors,” says CEO & co-founder Alex Demkov. “Our new 200mm wafer helps our customers unlock innovation by solving the speed, size and production limitations of competing materials, signifying the transformation of decades of academic research into a scalable, practical solution.”

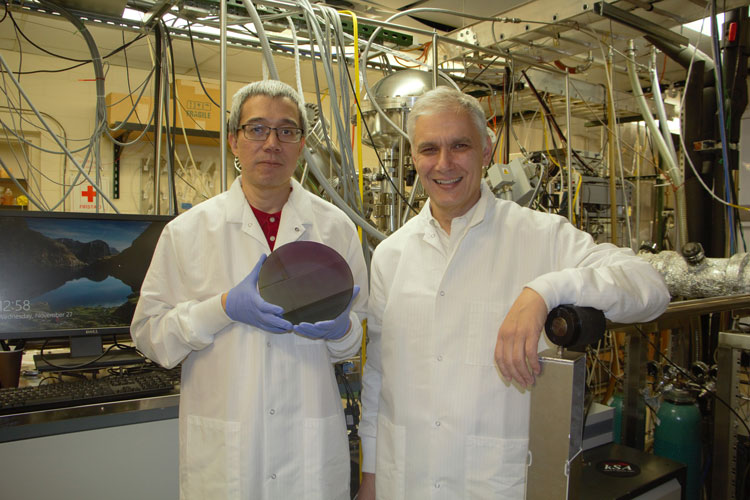

Co-founders Agham Posadas (CTO) and Alex Demkov (CEO) with a 200mm BaTiO3 wafer.

La Luce Cristallina notes that its BaTiO3 substrates are backed by university researchers, with scientists at UT Austin reporting the lowest propagation loss in a monolithic BaTiO3 waveguide utilizing the firm’s photonic materials. Researchers from the University of Illinois recently achieved an intrinsic quality factor of over 1 million with La Luce Cristallina’s low-loss BaTiO3-on-insulator integrated photonics. The firm currently supports customers in integrated photonics, quantum computing and other industries.

“La Luce Cristallina’s solutions signify continued technological evolution to support data-center interconnection, AI workloads and other high-capacity use cases,” says recent La Luce Cristallina customer Ron Kelly, CEO of Ambature Inc. “The company’s recent capability in manufacturing high-quality 200mm silicon wafers will enable Ambature to produce its quantum-based SQUID sensors and HPC processors at scale for data centers and AI in the growing military and commercial markets.”