News: Microelectronics

15 December 2023

A*STAR and centrotherm partner on 200mm silicon carbide technology

A partnership has been announced that combines the 200mm open R&D silicon carbide (SiC) pilot line of the Institute of Microelectronics (IME) at Singapore’s Agency for Science, Technology and Research (A*STAR) with the diffusion and annealing tools of centrotherm International AG of Blaubeuren, Germany.

Compared with traditional silicon-based semiconductors, the greater energy efficiency and higher switching frequencies of SiC-based semiconductors enable smaller power electronics modules to be built. SiC-based power modules can be found in a wide range of power applications, such as electric vehicles (EVs), electric trains, data centers and power grids. However, SiC substrates currently have a large number of defects that need to be skilfully managed.

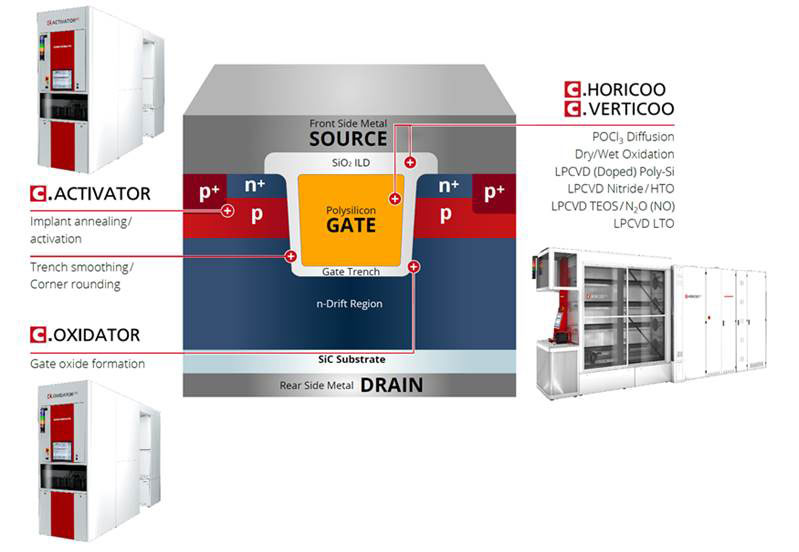

The collaboration aims to leverage IME’s process integration and device characterization capabilities and centrotherm’s specialized tools to develop thermal processes for SiC-based device fabrication, such as optimizing trench and gate oxide formation, so as to enhance the performance and reliability of SiC-based devices, such as metal–oxide–semiconductor field-effect transistors (MOSFETs) and diodes. As part of the partnership, centrotherm will establish a dedicated technology team in Singapore to offer technological know-how, process recipes, and on-site support.

Picture: Integrated SiC MOSFET technology solution being developed by A*STAR’s Institute of Microelectronics and centrotherm (image courtesy of A*STAR and centrotherm).

“Through the combination of IME’s 200mm SiC R&D pilot line with centrotherm’s advanced tools, we can accelerate R&D to better address the industry’s needs,” says Terence Gan, executive director of A*STAR’s IME.

“The shared vision, expertise and resources of both organizations promise to drive innovation, elevate industry standards and foster local growth in the field of semiconductor manufacturing,” says centrotherm’s chief technology officer Helge Haverkamp. “As we move towards the future of SiC and power electronics, we plan to further enhance diffusion and annealing specialization in wide-bandgap process modules and expand expertise into SiC, GaN and other innovative wide-bandgap materials.”

LPE and A*STAR’s IME to develop high-quality 200mm SiC and specialty epitaxy processes

A*STAR’s IME and Soitec to co-develop silicon carbide for EVs and high-voltage electronics

ST and A*STAR’s IME team on silicon carbide R&D for automotive and industrial power electronics